Para ahli merekomendasikan:

Fitur utama dari Metdeem Skeleton Bucket

Metdeem kerangka ember digunakan untuk penggalian bahan longgar & Pemisahan (proyek kota/pertanian/kehutanan/air).

Disarankan untuk memilih model ember grid dengan kapasitas yang mirip dengan excavator’ s ember standar

Berat peralatan tidak boleh melebihi 80% dari kapasitas angkat excavator

Aliran sistem hidrolik harus berada dalam kisaran yang diperlukan oleh peralatan

– Pemisahan tanah-batu konvensional: celah 50-80mm

– Pengambangan sungai: celah 30-50mm

– Klasifikasi limbah konstruksi: celah 80-120mm

– Pemeriksaan tambang: celah 100-150mm

– Kondisi kerja dengan bahan batu keras: Strip grid yang diperkuat dan gigi pelindung tahan aus perlu dikonfigurasi

– Bahan lembab dan lengket: Disarankan untuk memilih desain anti-penyumbatan celah lebar

– Lingkungan korosif: Galvanisasi atau perawatan lapisan khusus adalah opsional

– Ketika digunakan bersama dengan fungsi goyang excavator, dapat meningkatkan efisiensi skrining sebesar 30%

-Secara teratur membersihkan celah grid untuk mencegah penyumbatan

– Sesuaikan sudut kerja sesuai dengan kandungan kelembaban bahan

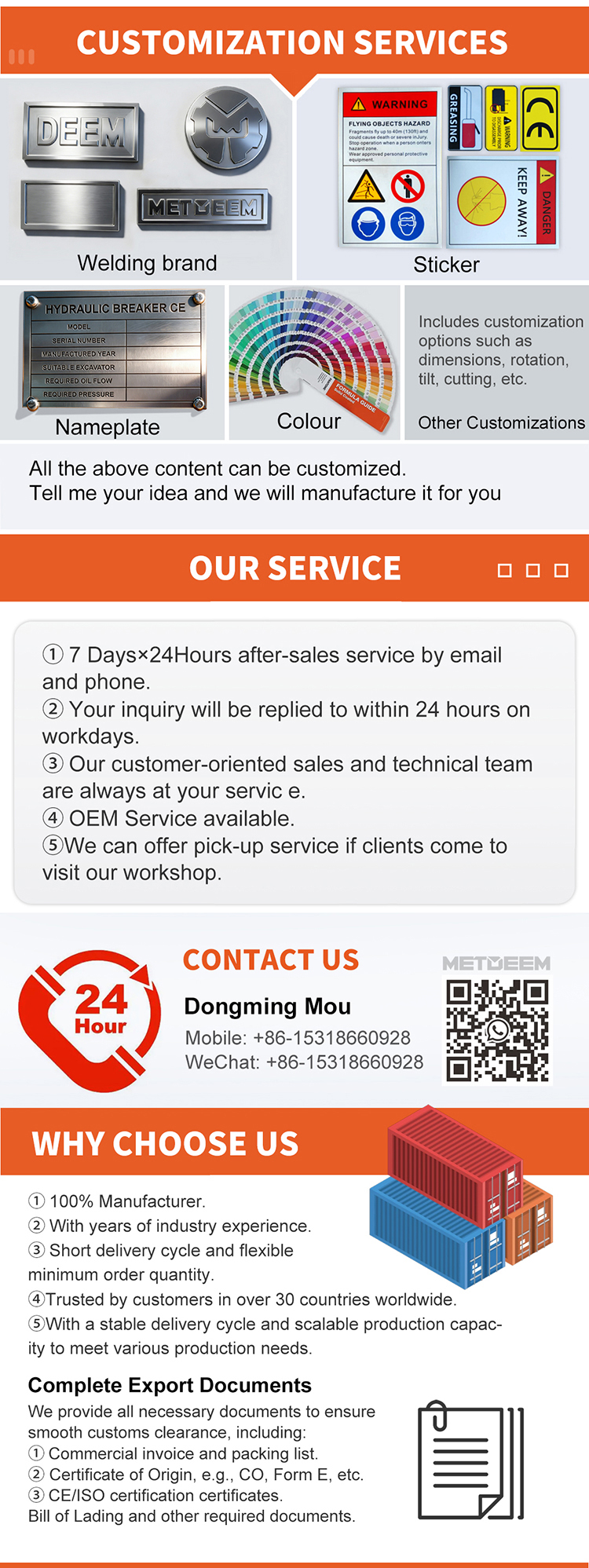

Layanan kami–Layanan Pra-penjualan dan Transaksi

Jaminan–Kebijakan Jaminan Purna Jual

Yantai Hansheng Heavy Industry Co., Ltd.

Dukungan teknis: Beijing Xinhulian Technology Co., Ltd