Para ahli merekomendasikan:

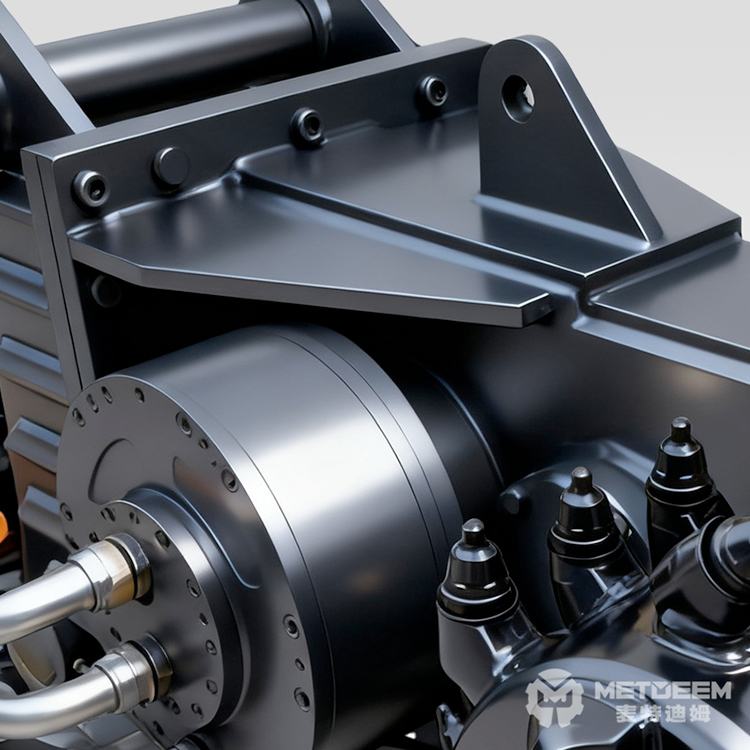

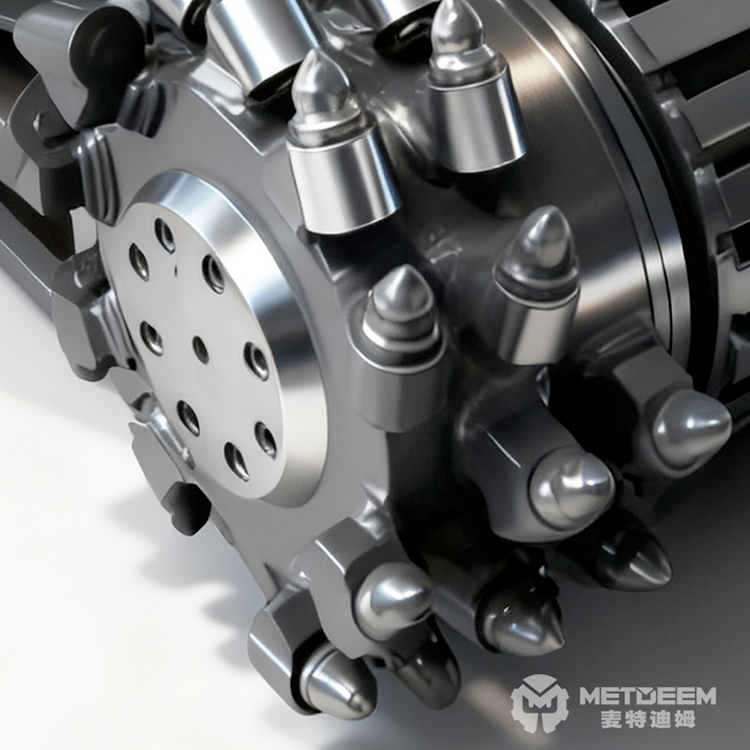

Pemotong Drum Metdeem adalah lampiran berkinerja tinggi yang dirancang untuk pemotongan presisi, penggilingan, dan tugas penggalian dalam proyek konstruksi, pertambangan, terowongan, dan pembongkaran.

Pengantar Produk Penyulingan

Fitur utama dari Metdeem Drum Cutter

– Keuntungan Utama dan Sorotan Produk

Pemotong Drum Metdeem Dikenal karena efisiensi dan fleksibilitasnya:

Metdeem Drum Cutter adalah solusi yang dapat diandalkan untuk bekerja di lingkungan yang menantang dan pada bahan keras seperti batu, beton, dan asfalt.

Parameter Model dan Panduan Kompatibilitas Pemilihan:

| ltem/Model | Unit | DM-05 | DM-10 | DM-15 | DM-20 | DM-30 | DM-40 |

| Berat | Kilogram | 310 | 410 | 780 | 1350 | 1650 | 2150 |

| Aliran kerja | L / menit | 30-65 | 50-110 | 75-130 | 150-320 | 180-400 | 225-510 |

| Tekanan kerja | Rumah | 220-320 | 220-320 | 220-320 | 220-320 | 220-350 | 220-350 |

| Kekuatan pemotongan | N | 8-11 | 13-19 | 19-27 | 31-45 | 44-70 | 55-84 |

| Daya nominal | kualitas | 25 | 35 | 50 | 90 | 120 | 165 |

| Excavator yang cocok | Ton | 2-7 | 7-16 | 12-18 | 18-30 | 22-38 | 35-65 |

♥ Spesifikasi peralatan ini dapat berubah untuk perbaikan.

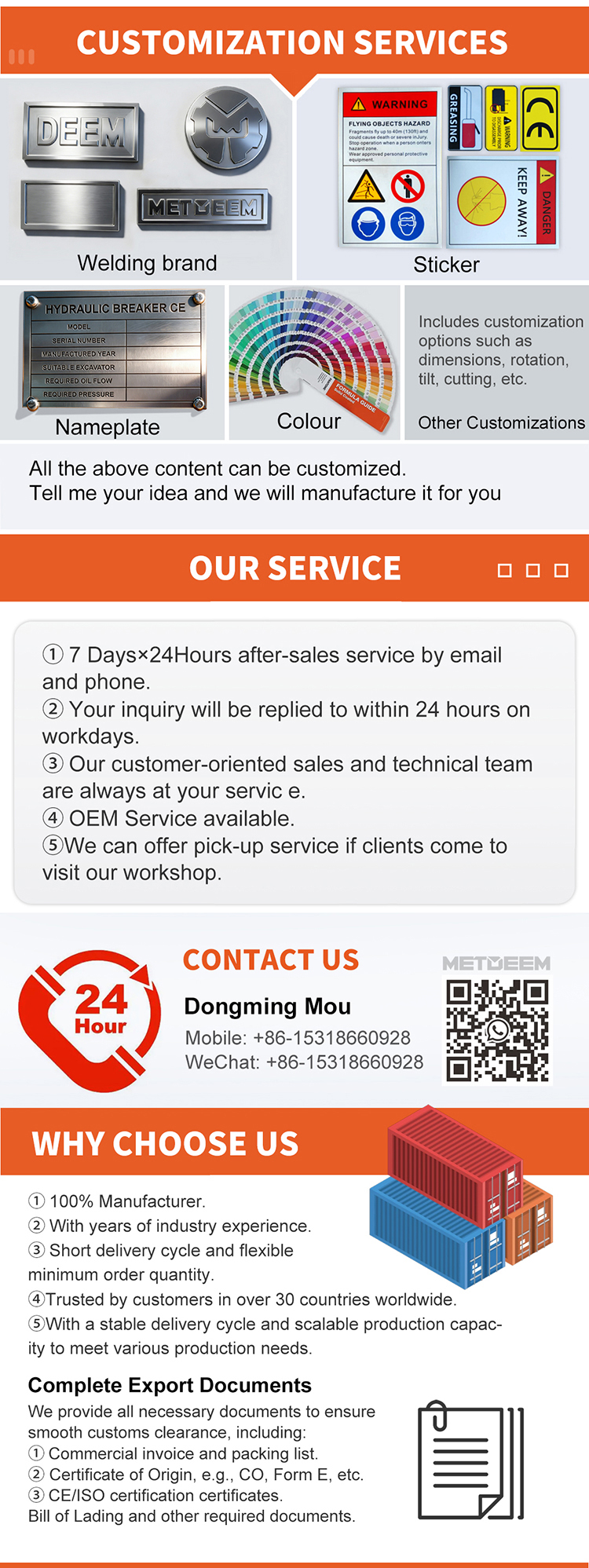

Deskripsi rinci dari produsen’ layanan komprehensif dan kekuatan

Pabrik METDEEM berkomitmen untuk membangun pengalaman kerjasama yang komprehensif dari kontak hingga penggunaan jangka panjang. Berikut adalah deskripsi rinci kekuatan inti dan komitmen kami:

Yantai Hansheng Heavy Industry Co., Ltd.

Dukungan teknis: Beijing Xinhulian Technology Co., Ltd