Gli esperti raccomandano:

– Introduzione completa del prodotto

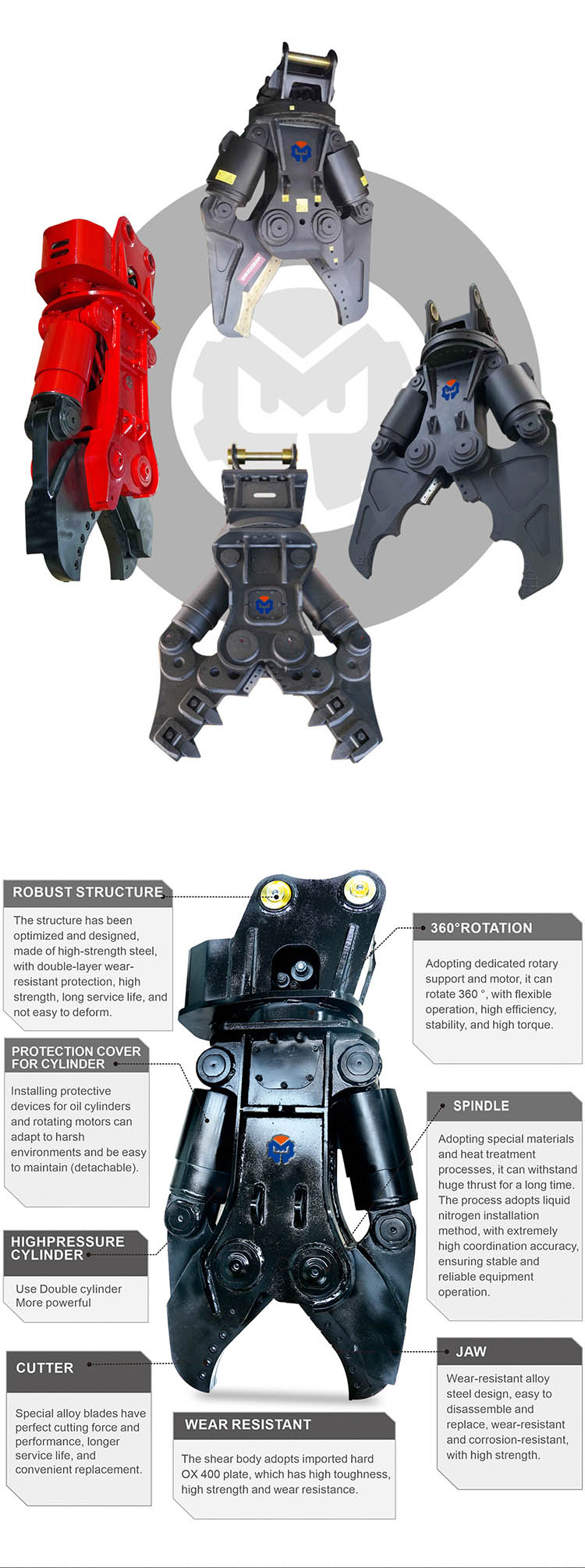

Caratteristiche principali di Metdeem Double Cylinder Shear/Multi Shear

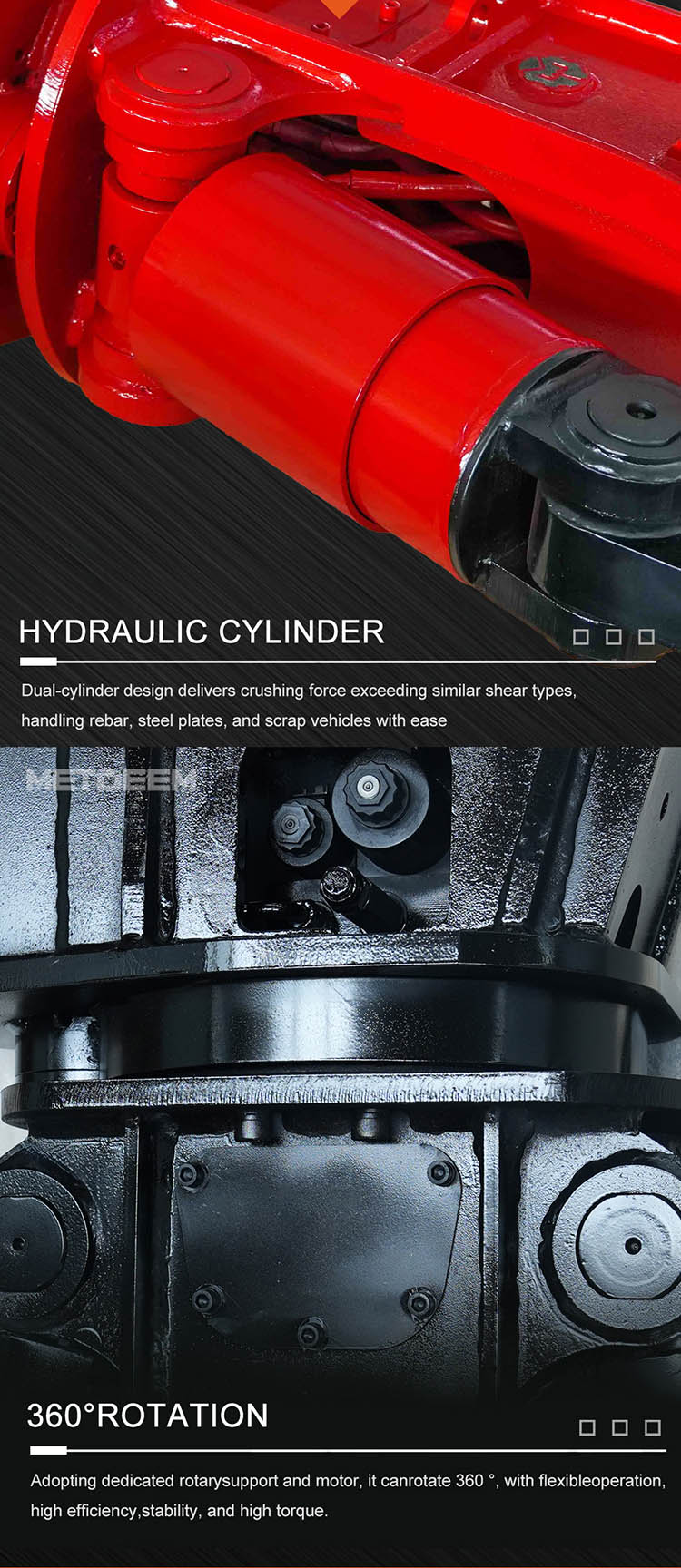

Metdeem doppio cilindro taglio/Multi taglio sono progettati per la demolizione dell'edificio, il taglio dell'acciaio e altre operazioni di frantumazione e taglio.

Parametri del modello del prodotto e guida di selezione:

| Articolo/Modello | Unità | DM100 | DM150 | DM290 | DM390 | DM100 | DM150 | DM290 | DM390 |

| Peso | kg | 500 | 1100 | 2850 | 3300 | 500 | 1000 | 2500 | 2800 |

| Apertura | millimetri | 500 | 650 | 850 | 850 | 480 | 750 | 1000 | 1100 |

| Lama lunghezza | millimetri | 400 | 500 | 670 | 670 | 120 | 140 | 240 | 300 |

| Altezza | millimetri | 1360 | 1820 | 2350 | 2350 | 1360 | 1820 | 2300 | 2300 |

| Larghezza | millimetri | 810 | 1080 | 1350 | 1350 | 810 | 1080 | 1350 | 1350 |

| Schiacciamento Forza | tonnellata | 180 | 240 | 300 | 400 | 85 | 110 | 220 | 240 |

| Taglio forza | tonnellata | 90 | 115 | 165 | 260 | 45 | 50 | 80 | 100 |

| Valutato pressione | bar | 180 | 240 | 300 | 300 | 160 | 240 | 300 | 300 |

| Valutato Flusso | lpm | 180 | 230 | 260 | 380 | 180 | 230 | 260 | 380 |

| Valutato pressione | bar | 180 | 240 | 300 | 300 | 180 | 240 | 300 | 300 |

| Adatto Scavatore | tonnellata | 6-9 | 13-16 | 20-30 | ≥30 | 6-9 | 13-16 | 20-30 | ≥30 |

♥ Le specifiche di questa attrezzatura sono soggette a modifiche per miglioramenti.

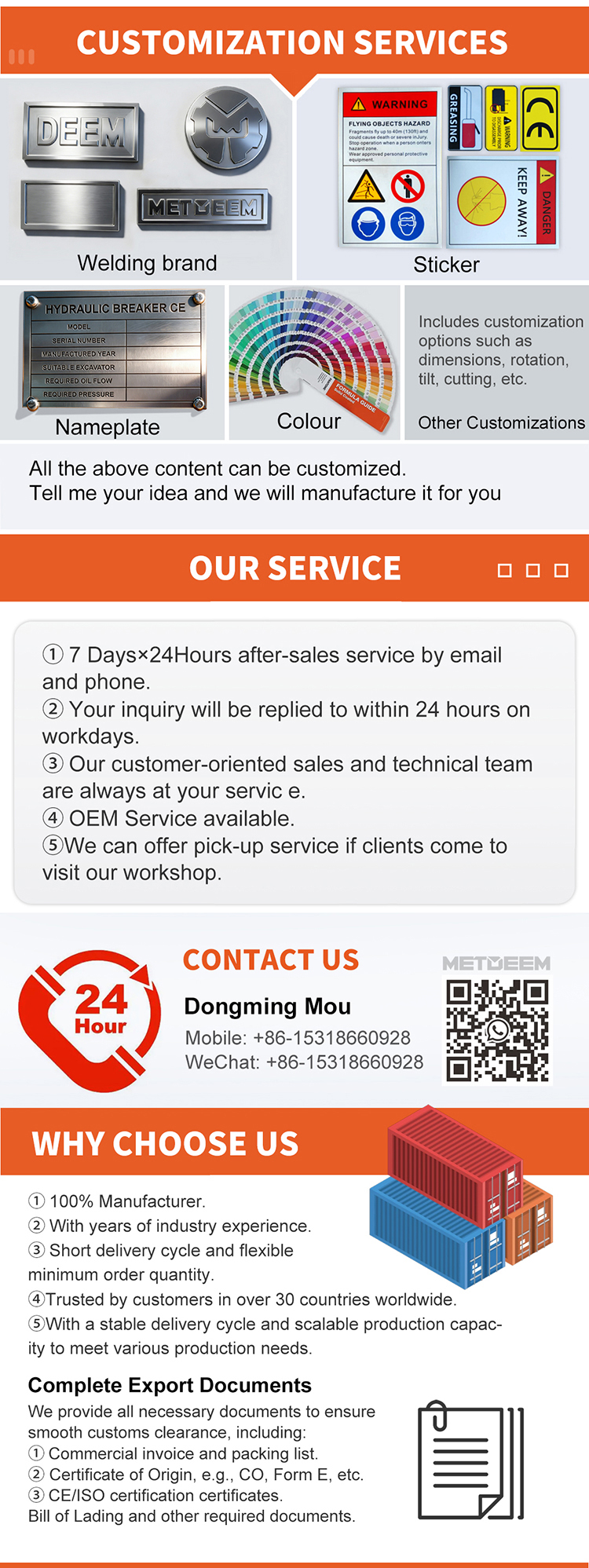

Servizi commerciali internazionali

Garanzia post-vendita

OEM & amp; Cooperazione ODM

Capacità di adattamento globale degli escavatori

Fabbrica R & amp; D e qualificazioni di fabbricazione

Yantai Hansheng Heavy Industry Co., Ltd.

Supporto tecnico: Beijing Xinhulian Technology Co., Ltd