METDEEM Hydraulic Breaker Comprehensive Application Guide: High-Efficiency Solutions for Diverse Scenarios

Na engenharia moderna, construção e extração de recursos, equipamento eficiente e confiável é fundamental para melhorar a produtividade. METDEEM quebradores hidráulicos, com nosso design avançado, construção duradoura e extensa gama de modelos, se tornaram ferramentas essenciais em uma ampla gama de aplicações, desde demolição de precisão até operações de quebramento pesado. Este artigo demonstrará através de análise detalhada de cenários como os breakers hidráulicos do METDEEM fornecem soluções personalizadas de alta eficiência para diferentes indústrias.

Construir Projetos de Demolição e Renovação: Um Modelo de Precisião, Flexibilidade e Amicidade Ambiental

As operações de demolição na indústria da construção requerem equipamentos que combinam energia, precisão e amigabilidade ambiental. Os quebradores hidráulicos METDEEM, com seu desempenho versátil, demonstram adaptabilidade excepcional no campo da demolição, oferecendo soluções confiáveis para várias tarefas de construção.

Miniature Excavator Adaptation Solution

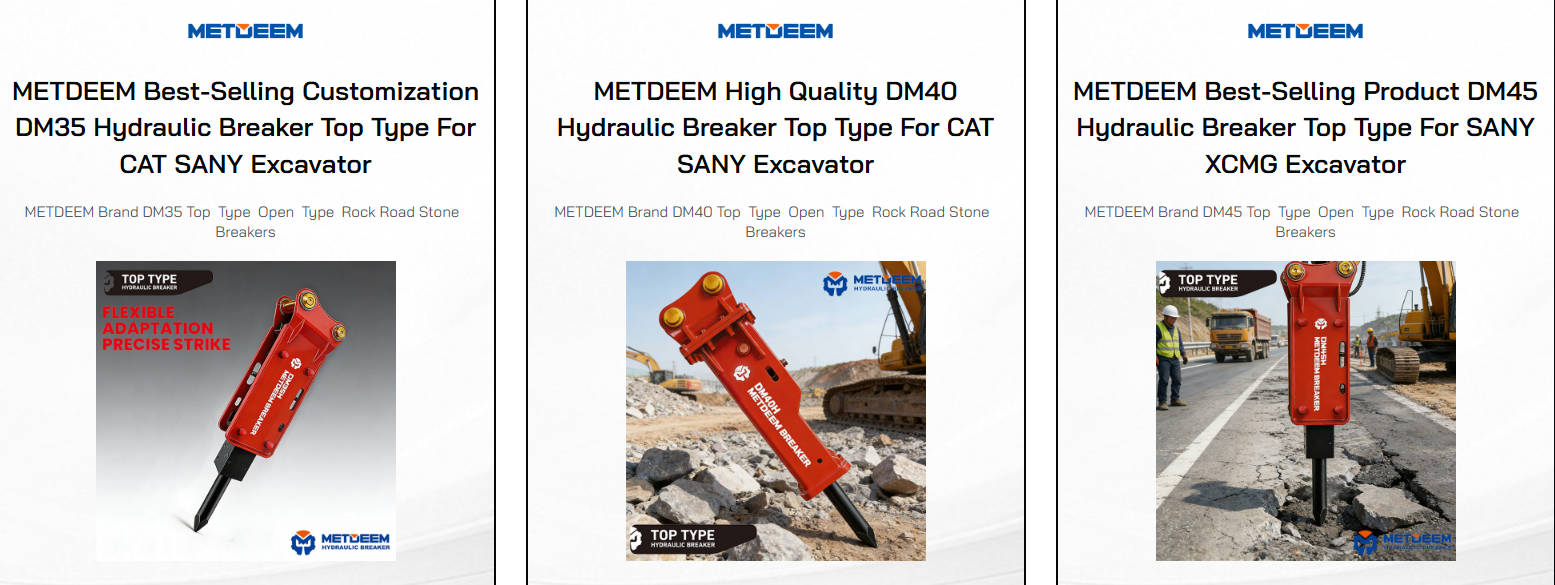

Para tarefas de demolição em espaços interiores confinados, incluindo projetos de quebra de paredes e pequenos fundamentos, recomendamos usar mini-excavadores menores de 2 toneladas, parejados com quebradores hidráulicos de METDEEM DM35 ou DM45, projetados para operações eficientes e de alto desempenho em ambientes estreitos. O tamanho compacto permite movimento livre em bairros estreitos, escadas e espaços interiores, realizando tarefas altamente eficientes que são difíceis de alcançar manualmente.

Capacidade de Operação Multi ângulo

O DM35 e DM45 estão disponíveis tanto em design Top Type como Box Type. O Top Type quebrador hidráulico apresenta uma estrutura racionalizada e excele em quebra de múltiplos ângulos. Os operadores podem facilmente cortar paredes horizontalmente, quebrar concreto no teto num ângulo, ou quebrar o chão para baixo, tornando-a uma máquina versátil que aumenta grandemente a gama operacional e o valor de um único pedaço de equipamento.

Tecnologia silenciosa para ambientes sensíveis

O controle do ruído é um requisito crítico em áreas residenciais urbanas, particularmente perto de hospitais, escolas e áreas comerciais, onde as regras de poluição do ruído são mais estritas, e METDEEM’ s Caixa Tipo de quebrador hidráulico oferece uma solução com ruído reduzido e vibração. Ele encerra completamente o núcleo de impacto com uma concha completamente encerrada, integrando múltiplas camadas de blocos húmidos de borracha de alto desempenho. Esse design absorve e bloqueia efetivamente até 70% do ruído de impacto e vibração, reduzindo significativamente a poluição de ruído e satisfazendo exigências rigorosas de construção ambiental. Também melhora consideravelmente o conforto dos operadores e reduz a fadiga durante longas horas de trabalho.

Construção de infraestruturas de estrada e túnel

A construção de estradas frequentemente encontra obstáculos geológicos imprevistos, exigindo equipamento com poderosas capacidades de quebra para garantir que os prazos do projeto sejam cumpridos.

Tratamento no fundo da estrada e remoção dos obstáculos

Durante a excavação na estrada e no fundo da estrada, quando se encontram camadas profundas e duras de rochas ou grandes pedras, o quebrador hidráulico METDEEM fornece uma alternativa segura e eficiente aos métodos tradicionais de explosão, reduzindo riscos de segurança e atrasos de projetos associados às aprovações de explosão. Também pode clarar exatamente as rochas obstruídas durante a construção de canais de drenagem e corte de inclinações, assegurando um alinhamento suave do projeto.

Escavação de túnel e terminação

Durante a excavação do túnel, os quebradores hidráulicos METDEEM são ideales para quebrar seções de rocha dura e ajustar o perfil de excavação para preparar uma superfície estável para sistemas iniciais de suporte do túnel. [UNK] Sua força de impacto controlável minimiza perturbações à rocha ao redor, melhorando a segurança da construção.

Modelos Especializados Recomendados

Para aplicações que envolvem principalmente quebramento de superfície rodoviária e excavação planar, o quebrador hidráulico METDEEM Side Type é ideal. Sua estrutura é reforçada para impactos planares contínuos, e suas partes de conexão são mais robustas e duradouras, capazes de resistir a operação prolongada e de alta intensidade para assegurar o progresso do projeto.

Colocação de tubos municipais: Pioneiros do Espaço Subterrestre Urbano

A instalação e manutenção de tubos subterrâneos urbanos – como abastecimento de água, drenagem, gás, eletricidade e comunicações – são projetos essenciais de infraestrutura críticos para uma cidade’ é uma operação eficiente.

Escavação de tendências de alta eficiência

Quando quebram superfícies urban as pavimentadas (como asfalto e pavimentos de concreto) e fundamentos de concreto reforçados existentes, quebradores hidráulicos METDEEM demonstram alta eficiência. Eles podem rapidamente e limpo quebrar e cavar trinchas, seguidas de limpeza de balde de excavadores, reduzindo significativamente o ciclo de construção e reduzindo o impacto no tráfego urbano e residentes’ - vidas.

Avantagens nos espaços confinados

Ao colocar gasodutos entre edifícios existentes ou nas ruas ocupadas, o espaço de trabalho é muitas vezes extremamente limitado. Os quebradores hidráulicos METDEEM, compatíveis com cavadores de pequeno ou médio tamanho, são a primeira escolha para tais condições devido à sua manevrabilidade flexível e ao pequeno raio de viragem.

Seleção de Adaptação à Condição de Trabalho

Para operações contínuas de excavação de trenches comuns na engenharia municipal, quebradores hidráulicos de tipo lateral, devido a sua robusta estrutura e design centro de gravidade que facilita impacto planar, oferecem eficiência de trabalho mais estável e uma vida de serviço mais longa, reduzindo efetivamente os custos gerais de construção.

Mining and Quarrying: Power Sustained Under Heavy Load Conditions

A mineração coloca demandas extremas na confiabilidade do equipamento, durabilidade e capacidade de esmagamento.

Cruzamento primário e secundário

METDEEM grandes quebradores hidráulicos não são usados apenas para tirar minerais de paredes de rocha, mas sua aplicação central está em esmagamento secundário. Grandes pedaços de minerais produzidos após explosão ou tiragem primária devem ser esmagados para um tamanho adequado para o transporte e entrada em esmagadores de mandíbula (tipicamente menos de 1 metro), um passo crucial para otimizar todo o fluxo de processamento de minerais.

Soluções de Modelo de Trabalho Pessoal

Esses cenários utilizam principalmente DM175 Hydraulic Breaker Top Type

e quebradores hidráulicos pesados de tipo lateral maiores, que devem ser montados em grandes excavadores de 35 toneladas ou mais. Sua imensa energia de impacto pode facilmente lidar com as pedras mais difíceis e mineral.

Avantagens do Partidor do tipo lateral com Estrutura Triangular

A estrutura triangular é conhecida pela sua estabilidade não comparada. O quadro é mais robusto e pode resistir a cargas de impacto extremos. Simultaneamente, o design com a maioria do núcleo exposto cria dissipação óptima de calor, assegurando estabilidade sustentada e tempo de uptime sob operação contínua de alta intensidade 24 horas em minas, maximizando a eficiência mineira.

Agricultura, floresta e Operações Especializadas de Condução de Pilos

A funcionalidade dos quebradores hidráulicos é alargada através da modificação dos anexos para se adaptar às necessidades mais diversas.

Aplicações convenientes de condução de pilhas

Ao substituir o bastão especializado de montagem (capa de pilha), pequenos e médios quebradores hidráulicos METDEEM (como DM68 Tipo de lado do quebrador hidráulico) pode ser instantaneamente transformada em motores de pilha de alta eficiência. Isso é amplamente utilizado na cerca de gado, instalação de pilhas de irrigação de terras agrícolas, construção de paisagens e instalação temporária de cerca em pequenos locais de construção, possibilitando a rápida e poupança de trabalho condução de pilhas de madeira ou de aço ligeiro para o chão.

Outras Funções Derivadoras

Além disso, quebradores hidráulicos também podem ser usados para operações auxiliares como compacção de solo, quebramento de gelo e instalação de carrinhos de segurança de táxi, mostrando seu valor básico como um anexo de excavadores multifuncionais.

Mantenimento e limpeza industrial

Em setores industriais específicos, quebradores hidráulicos fornecem soluções de manutenção seguras e eficientes.

Removação de bateria de caldeiro e forno

Grandes caldeiras, fornos de fundição e fornos rotativos em indústrias como metalurgia, energia e cimento muitas vezes desenvolvem anéis de chuva dura aderindo às paredes internas, afetando a eficiência térmica e posicionando perigos de segurança. Os quebradores hidráulicos METDEEM podem ser equipados com quebradores extra-longos e rigorosos, permitindo aos operadores controlar remotamente o cavador para operações de limpeza de uma distância segura quando o equipamento é fechado para manutenção. Esse método é mais seguro, mais detalhado e mais eficiente do que escolhas pneumáticas manuales tradicionais.

Demolição da Estrutura Industrial

Os quebradores hidráulicos do METDEEM também podem destruir precisamente fundações antigas, plataformas de concreto e bases abandonadas de equipamentos dentro de áreas fábricas, mesmo em ambientes restritos ao espaço.

Conclusão

Desde uma demolição urbana precisa para grandes operações mineiras, os quebradores hidráulicos METDEEM, com nossa matriz de modelo completo (que cobre o tipo de caixa, tipo lateral e tipo superior) e ampla gama de toneladagem (de mini-excavadores a excavadores ultra-grandes), fornecem soluções de quebramento profissionais e eficientes aos clientes em todo o mundo.

Escolhar o METDEEM não é apenas escolher um pedaço de equipamento, mas também escolher um parceiro apoiado por uma equipe de engenheiros profissionais. Estamos empenhados em fornecer conselhos de seleção de equipamentos otimizados baseados em suas condições de trabalho específicas, modelo de excavadores e objetivos de projeto, ajudando você a reduzir os custos, aumentar a eficiência e enfrentar todos os desafios.

FAQ

Q: Como escolho o modelo de quebrador hidráulico METDEEM certo para meu excavador?

A: A seleção é principalmente baseada no excavador’ s peso funcional e parâmetros do sistema hidráulico (taxa de fluxo e pressão). Por favor forneça seu excavador o modelo específico e os principais alvos de construção, e nossa equipe técnica recomendará o modelo e estilo mais adequados de quebradores hidráulicos para vocês.

Q: Quanto eficaz é a redução do ruído do quebrador hidráulico silencioso? Para que cenários é adequado?

A: O quebrador hidráulico do tipo de caixa, através de sua concha completamente fechada e estrutura interna de absorção de choque, reduz significativamente o ruído de impacto e vibração, tornando-o particularmente adequado para cenários com exigências estritas de controle do ruído, como áreas residenciais, áreas em torno das escolas e hospitais, e construção nocturna.

Q: Quais são as vantagens essenciais da tipo lateral quebrador hidráulico em comparação com outros tipos?

A: As vantagens essenciais do tipo lateral de quebra hidráulica estão em sua superior estabilidade estrutural e excelente desempenho de dissipação de calor. Sua estrutura triangular robusta e seu design exposto permitem resistir a operação contínua a longo prazo e de alta intensidade em ambientes difíceis como minas, demonstrando durabilidade excepcional.

Q: Pode o quebrador hidráulico METDEEM ser usado para montagem?

A: Sim. Para modelos menores como DM100Hydraulic Breaker Box Type, substituindo a bastão de cobertura dedicada, pode ser usada para conduzir pilhas de madeira, pequenas pilhas de metal, etc., e é amplamente usada em projetos de construção de cercas, agricultura e paisagem.

Q: Quais acessórios chave são necessários ao comprar um quebrador hidráulico?

A: Os acessórios chave incluem um queixel que corresponde ao material (como um queixel padrão, queixel plano largo, ou queixel de montagem), um kit de tubos hidráulicos para conectar ao excavador, e um paréntese (base de montagem). Além disso, a manutenção regular requer lubrificação; Recomenda-se ter uma caixa de ferramentas de selos e peças de repouso comum para assegurar o funcionamento contínuo do equipamento.