Khi đối mặt với các thách thức của đá cứng, bê tông thép gia cố nặng hoặc hoạt động liên tục cường độ cao, các hạn chế của máy phá thủy lực thông thường nhanh chóng trở nên rõ ràng - sự hư hỏng thường xuyên, hiệu quả thấp và chi phí bảo trì cao đang xói mòn lợi nhuận dự án của bạn. Các Máy ngắt thủy lực tăng cường METDEEM được tạo ra để giải quyết hoàn toàn vấn đề này. Nó’ Không chỉ là nâng cấp sản phẩm mà còn là sự đổi mới toàn diện từ khoa học vật liệu và kỹ thuật chính xác đến quản lý hiệu suất, được thiết kế đặc biệt cho các chuyên gia ưu tiên tổng chi phí sở hữu và lợi nhuận đầu tư cuối cùng. Bài viết này sẽ xem xét cách METDEEM Reinforced Hydraulic Breaker vượt qua các tiêu chuẩn công nghiệp trong từng chi tiết, trở thành Đối tác đáng tin cậy của bạn cho các điều kiện làm việc đòi hỏi nhất.

Đường phòng thủ đầu tiên không thể phá vỡ: Hệ thống bảo vệ bên ngoài toàn diện

Môi trường hoạt động khắc nghiệt là thử nghiệm chính của độ bền thiết bị. Máy phá thủy lực tăng cường METDEEM có hệ thống bảo vệ bên ngoài đa lớp, tối đa hóa tuổi thọ thiết bị từ các điểm tiếp xúc.

thép mangan dày FRame và Wear-Resistant Armor

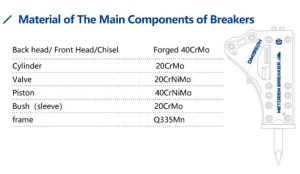

Vật liệu khung cốt lõi sử dụng tấm thép mangan cường độ cao Q335 dày, với hàm lượng mangan tối ưu hóa để cải thiện khả năng chống tác động, có độ dày tổng thể lớn hơn 2 mm so với các sản phẩm thông thường. Điều này trực tiếp dẫn đến sự cải thiện đáng kể về khả năng chống tác động và kiểm soát biến dạng. Tại các cạnh và góc của khung dễ bị tác động và mài mòn nhất, chúng tôi hàn một cách sáng tạo các dải chống mài mòn đặc biệt. Thiết kế này tạo thành một phòng thủ tích cực “ vành đai giáp, ” deflecting hiệu quả và chống lại sự xói mòn và mài mòn của cát và mảnh vỡ, cung cấp bảo vệ gấp đôi cho cơ chế cốt lõi và kéo dài đáng kể tuổi thọ tổng thể của máy.

Vật khóa lớp hàng không vũ trụ và lớp phủ bền

Thiết bị’ Sự ổn định bắt đầu ở mọi điểm kết nối. Tất cả các thiết bị dính quan trọng bảo đảm cơ chế sử dụng vít nắp đầu ổ cắm lục giác cực cao 12,9 lớp. Đây là lớp độ bền cao nhất thường được sử dụng trong thiết bị công nghiệp và kỹ thuật nặng, có độ bền kéo vô song và khả năng chống mệt mỏi, đảm bảo rằng các điểm kết nối sẽ không bao giờ biến dạng, phá vỡ hoặc nới lỏng dưới hàng ngàn giờ tần số cao, rung dữ dội, về cơ bản loại bỏ các mối nguy hiểm an toàn cấu trúc. Hơn nữa, thông qua nhiều quá trình xử lý trước chuyên nghiệp và phun thân thiện với môi trường, bề mặt sơn không chỉ có độ bóng kim loại và kết cấu tuyệt vời, mà còn có độ dính dáng cực kỳ mạnh mẽ, chống ăn mòn và chống trầy xước, đảm bảo rằng thiết bị duy trì vẻ ngoài chuyên nghiệp ngay cả sau nhiều năm thời tiết và hoạt động khó khăn.

Cách mạng hệ thống động cơ cốt lõi: Vật liệu cấp quân sự và quy trình sản xuất chính xác

Hiệu suất và độ tin cậy thực sự xuất phát từ những gì vô hình với mắt thường. Các METDEEM cắt thủy lực tăng cường đã trải qua một sửa chữa hoàn toàn của các vật liệu và quy trình cho bốn thành phần năng lượng cốt lõi của nó.

Bush và Sleeve300% -500% Tăng khả năng chống mòn và tuổi thọ

Là thành phần trực tiếp chà xát chống lại móc thép và mòn đi nhanh nhất, máy phá thủy lực thông thường thường sử dụng thép 45 # cho bụi và tay áo của họ. Tuy nhiên, METDEEM chọn thép hợp kim 40CrNiMo cấp cao hơn và áp dụng một quy trình xử lý nhiệt độc đáo, đạt được độ cứng Rockwell đáng kinh ngạc của HRC60 °. Các thử nghiệm trong phòng thí nghiệm và thực địa cho thấy sự cải thiện tuổi thọ mòn khoảng 3-5 lần trong điều kiện làm việc tương tự, giảm đáng kể thời gian ngừng hoạt động và chi phí phụ tùng.

Piston: Được đánh giá khoa học và tùy chỉnh cho độ bền cuối cùng

Piston là trái tim của máy, truyền năng lượng tác động. Chúng tôi từ chối “ một kích thước phù hợp với tất cả” tiếp cận và thực hiện các piston được đánh giá khoa học và tùy chỉnh:

- Pi-tôn thiết bị nhỏ (thích hợp cho máy xúc < 20 tấn):Được làm bằng thép hợp kim 40CrNiMo, cân bằng sức mạnh và độ bền.

- Piston thiết bị trung bình (thích hợp cho máy xúc 20-35 tấn):Nâng cấp lên thép hợp kim 20Cr2Ni4, cung cấp độ bền tác động vượt trội.

- Pi-tôn thiết bị lớn (thích hợp cho máy xúc > 35 tấn):Được làm bằng thép đặc biệt hợp kim vanadium cao cấp (616V hoặc tương đương), được phát triển đặc biệt để chống mệt mỏi tác động cực đoan.

Tùy chỉnh này đảm bảo rằng mỗi piston hoạt động đáng tin cậy trong phạm vi tải được thiết kế của nó, với nguy cơ biến dạng hoặc nứt mệt mỏi giảm đáng kể. Độ cứng bề mặt cao ngăn chặn trầy xước và rò rỉ dầu, và vật liệu chống ăn mòn, duy trì hiệu suất nhất quán ngay cả sau khi lưu trữ lâu dài và sử dụng sau đó.

Xi lanh: Tăng cường hai quy trình để loại bỏ rủi ro biến dạng

Xi lanh chịu được các tác động thủy lực áp suất cao định kỳ. Chúng tôi thay thế thép đúc thông thường bằng thép rèn hợp kim 20CrMo làm vật liệu cơ bản, dẫn đến hạt mịn hơn và sức mạnh cơ bản cao hơn. Thông qua xử lý cứng bề mặt, một lớp siêu cứng khoảng 2mm được tạo ra trên tường bên trong của xi lanh, làm tăng đáng kể khả năng chống tác động. Quan trọng là, chúng tôi sử dụng công nghệ giảm căng thẳng bắn để giải phóng chính xác và loại bỏ căng thẳng còn lại trong vật liệu trước, giảm đáng kể nguy cơ biến dạng xi lanh, rò rỉ dầu và van dính trong hoạt động tần số cao dài hạn, rò rỉ hoặc gây nhiễu van do rung hoạt động dài hạn.

Van: Độ chính xác cấp Micron, kiểm soát nhịp điệu nổi bật

Van là “ não” Kiểm soát lực tấn công và tần số. Chúng tôi sử dụng thép hợp kim 20CrNiMo, rèn nhiều lần, tiếp theo là xử lý bề mặt carbonitriding để tăng cường khả năng chống mài mòn. Cuối cùng, nó trải qua gia công siêu chính xác ở mức micron (μm) bằng cách sử dụng máy mài CNC chính xác cao. Điều này đảm bảo lõi van và tay áo van có dung sai phù hợp tốt nhất có thể, cho phép chuyển mạch dầu tức thời giảm thiểu rò rỉ bên trong đến mức cực thấp, trực tiếp dẫn đến đầu ra lực tấn công mạnh mẽ hơn và nhịp điệu làm việc ổn định và mượt mà hơn.

Từ lợi thế công nghệ đến lợi ích kinh tế: Hiệu suất cao có thể định lượng, tiết kiệm năng lượng và giảm chi phí

Giá trị cuối cùng của máy phá thủy lực tăng cường METDEEM nằm trong khả năng dịch công nghệ kỹ thuật cấp cao thành tăng trưởng lợi nhuận rõ ràng cho người dùng.

Tăng hiệu quả: Sử dụng năng lượng thủy lực vượt quá 98%

Bằng cách kiểm soát khoảng trống của các bộ phận di chuyển như piston và xi lanh đến mức micron, chúng tôi đã giảm rò rỉ dầu thủy lực áp suất cao bên trong xuống gần như không. Dưới cùng một đầu vào thủy lực máy xúc (cùng một áp suất và dòng chảy), điều này dẫn đến sự gia tăng lực tác động trên 30%, với sự gia tăng tương ứng về tần số tác động, trực tiếp dẫn đến hiệu quả công việc cao hơn.

Tiết kiệm năng lượng đáng kể: Giảm tải đơn vị chính và tiêu thụ nhiên liệu

Hiệu quả chuyển đổi năng lượng cực kỳ cao có nghĩa là máy xúc’ Hệ thống thủy lực không cần hoạt động với tải đầy đủ trong thời gian dài để lái bộ phá thủy lực. Thử nghiệm thực tế cho thấy điều này làm giảm hiệu quả tiêu thụ nhiên liệu của đơn vị chính 5% -15%. Đối với các dự án với hàng ngàn giờ hoạt động hàng năm, tiết kiệm chi phí nhiên liệu sẽ đáng kể, đồng thời cũng giúp giảm mài mòn lâu dài trên máy xúc ’ s hệ thống thủy lực.

Giảm chi phí tổng thể: Cải thiện thời gian hoạt động và chi phí vòng đời thấp hơn

- Cải thiện hiệu quả và giảm chi phí:Tăng công suất và tốc độ có thể rút ngắn giờ làm việc cá nhân 25% -40%, tăng tốc tiến bộ tổng thể của dự án và trực tiếp giảm chi phí vận hành lao động và thiết bị.

- Giảm chi phí bảo trì:Tuổi thọ kéo dài của các thành phần cốt lõi làm giảm đáng kể tỷ lệ thất bại, làm giảm đáng kể thời gian ngừng hoạt động không có kế hoạch và tần số bảo trì. Chu kỳ thay thế phụ tùng mở rộng dẫn đến chi phí bảo trì lâu dài thấp hơn nhiều so với máy phá thủy lực thông thường.

- Lợi nhuận đầu tư cao:Mặc dù chi phí mua ban đầu cao hơn một chút, độ bền vượt trội của nó, hiệu quả làm việc cực kỳ cao và chi phí vận hành cực kỳ thấp cho phép lợi nhuận đầu tư nhanh hơn (thường là 6-12 tháng) và tạo ra lợi ích kinh tế vượt xa các mô hình thông thường trên toàn bộ thiết bị. S vòng đời.

Kết luận: Sinh ra để xác định tiêu chuẩn năng suất

Lựa chọn một máy phá thủy lực tăng cường METDEEM không chỉ là mua một máy; nó’ s áp dụng một giải pháp năng suất tiên tiến tập trung vào độ tin cậy cuối cùng và hiệu quả chi phí vòng đời. Bằng cách tích hợp các tiêu chuẩn vật liệu cấp quân sự, quy trình sản xuất chính xác và quản lý năng lượng thông minh, nó xác định lại tiêu chuẩn hiệu suất cho các hoạt động nghiền cường độ cao. Cho dù bạn’ Đối mặt với đá granit không thể thâm nhập, cấu trúc bê tông thép phức tạp hoặc các nhiệm vụ khai thác mỏ đòi hỏi hoạt động liên tục 24/7, máy phá thủy lực tăng cường METDEEM là một tài sản chiến lược đảm bảo các dự án tiến hành theo lịch trình, duy trì hiệu quả về chi phí và tối đa hóa lợi nhuận. Đối với các nhóm kỹ thuật nhằm thiết lập một lợi thế cạnh tranh cốt lõi, nó’ là một nền tảng không thể thiếu, thúc đẩy thành công và đảm bảo tương lai.

Câu hỏi thường gặp

Q: Sự khác biệt chính giữa bộ phá thủy lực tăng cường METDEEM và mô hình tiêu chuẩn là gì?

A: Sự khác biệt cơ bản nhất nằm ở “Sự siêu vượt hệ thống.”

- Đây là’ t chỉ là một cải tiến cho một thành phần duy nhất, nhưng một nâng cấp toàn diện từ khung bọc thép dày và các thiết bị dính cấp hàng không vũ trụ đến việc sử dụng thép hợp kim đặc biệt và các quy trình xử lý nhiệt độc quyền cho tất cả bốn thành phần năng lượng cốt lõi, đỉnh cao là độ chính xác sản xuất cấp micron.

- Điều này đảm bảo nó cung cấp hiệu suất mạnh mẽ hơn đáng kể trong cùng điều kiện, với độ bền và độ tin cậy tăng theo cấp số nhân.

Q: Làm thế nào là “ Tỷ lệ sử dụng năng lượng thủy lực 98% ” đạt được? Điều này mang lại lợi ích cụ thể gì cho dự án của tôi?

A: Điều này được đạt được thông qua gia công CNC chính xác cao, kiểm soát khoảng trống của các bộ phận di chuyển bên trong đến mức micromet, hầu như loại bỏ rò rỉ dầu áp suất cao. Lợi ích cụ thể là hai:

- Đầu tiên, cải thiện hiệu quả trực tiếp- với cùng một thiết bị và tiêu thụ nhiên liệu, nhiều vật liệu có thể bị nghiền, rút ngắn đáng kể thời gian xây dựng.

- Second, tiết kiệm năng lượng gián tiếp và bảo vệ máy- tải trọng trên máy xúc’ s hệ thống thủy lực được giảm, tiết kiệm nhiên liệu và giảm mài mòn trên các thành phần chính như lắp ráp bơm và van chính, kéo dài tuổi thọ của đơn vị chính.

Q: Tại sao các vật liệu khác nhau được sử dụng cho piston tùy thuộc vào máy xúc ’ Tăng lượng?

A: Điều này dựa trên phù hợp cơ học khoa học và phân tích lỗi. Máy xúc trọng lượng khác nhau sản xuất năng lượng tác động thủy lực khác nhau và có sức mạnh cấu trúc khác nhau, dẫn đến các loại và mức độ căng thẳng khác nhau trên piston. L

- Thiết bị nhỏ pistonyêu cầu hiệu suất toàn diện; Thiết bị kích thước trung bình piston cần độ bền cao kết hợp với độ bền cao để ngăn chặn gãy gãy; Thiết bị lớn piston phải chịu được mệt mỏi tác động cực đoan.

- Lựa chọn vật liệu được phân cấp đảm bảo rằng mỗi piston hoạt động trong cửa sổ thiết kế tối ưu và an toàn nhất của nó, tối đa hóa cả hiệu quả và độ bền, từ máy nhỏ nhất 15 tấn đến máy lớn nhất hơn 50 tấn.

Q: Máy phá thủy lực tăng cường có tương thích với tất cả các thương hiệu máy xúc không?

A: Hoàn toàn tương thích.

- Các thông số phù hợp cốt lõi cho máy phá thủy lực tăng cường METDEEM là máy xúc ’ s tấn, áp suất làm việc (Bar) và tỷ lệ dòng chảy dầu thủy lực (L / phút), bất kể thương hiệu máy xúc.

- Chúng tôi cung cấp một loạt sản phẩm hoàn chỉnh bao gồm các phân khúc khối lượng vi, nhỏ, trung bình, lớn và siêu lớn. Để đảm bảo hiệu suất tối ưu, chúng tôi khuyên bạn nên cung cấp thương hiệu và mô hình cụ thể của máy xúc của bạn, và các kỹ sư của chúng tôi sẽ khuyên và cấu hình chính xác bộ kết nối đường ống phù hợp nhất cho bạn.

Q: Việc chọn một máy phá thủy lực tăng cường sẽ thực sự dẫn đến chi phí bảo trì thấp hơn?

A: Vâng, chi phí bảo trì tổng thể dài hạn sẽ giảm đáng kể.

Logic cốt lõi là do khả năng chống mài mòn cực kỳ cao và khả năng chống mệt mỏi của các thành phần chính của nó, khoảng thời gian giữa các lỗi được mở rộng theo cấp số nhân. Điều này có nghĩa là:

- Thời gian ngừng hoạt động không có kế hoạch được giảm đáng kể, dẫn đến thời gian hoạt động thiết bị cực kỳ cao và tính liên tục của dự án;

- Tần suất thay thế các bộ phận dễ bị tổn thương giảm mạnh, giảm chi phí mua phụ tùng;

- Chi phí lao động bảo trì được giảm. Xem xét tuổi thọ 3-5 năm hoặc thậm chí lâu hơn, tổng chi phí bảo trì của nó thấp hơn nhiều so với các máy phá thủy lực thông thường đòi hỏi bảo trì thường xuyên, chứng minh một lợi thế rõ ràng về chi phí tổng thể của sở hữu.