Máy phá thủy lực là thiết bị cần thiết cho các hoạt động phá hủy và bảo trì đường bộ và xây dựng nền tảng và công việc khai thác đá. Thiết kế mở của máy phá thông thường tạo ra tiếng ồn quá mức đạt 120-130 dB trong các hoạt động tác động do đó dẫn đến các khiếu nại tiếng ồn xây dựng ở các khu vực đô thị đông dân. Sự phát triển của máy phá thủy lực im lặng phục vụ như một giải pháp chính cho các nhà thầu cần tuân thủ các quy định về tiếng ồn thắt chặt.

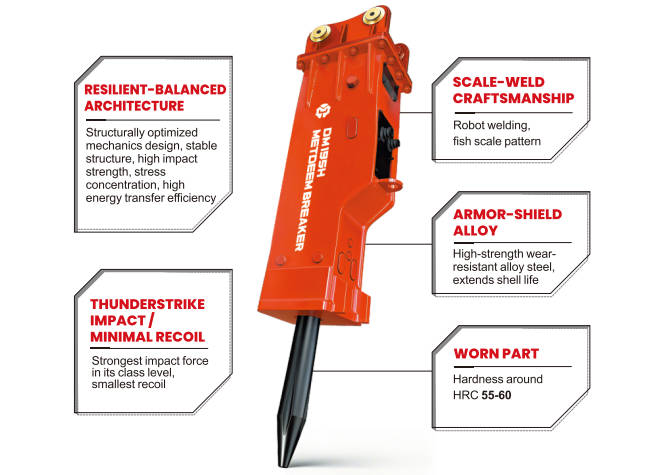

METDEEM đạt được hiệu suất mạnh mẽ thông qua hệ thống giảm tiếng ồn nhà ở hoàn chỉnh và công nghệ giảm rung duy trì năng lượng tác động ổn định.

Hiểu ô nhiễm tiếng ồn xây dựng

Điều gì gây ra tiếng ồn trên trang web làm việc

Máy móc nặng bao gồm máy xúc và máy cắt bê tông và máy phá thủy lực hoạt động tại hầu hết các địa điểm xây dựng. Việc vận hành của máy phá thủy lực chống lại đá và bê tông thép tạo ra âm thanh tác động lớn liên tục. Thiết kế mở của các bộ phá tiêu chuẩn tiết lộ hệ thống tác động bên trong của chúng vào không khí cho phép âm thanh và rung động thoát ra một cách tự do.

Tác động đến các cộng đồng xung quanh

Tiếng ồn tác động cường độ cao, lặp đi lặp lại có thể gây ra:

- Rối loạn với cư dân và doanh nghiệp gần đó.

- Căng thẳng, gián đoạn giấc ngủ và đau đầu.

- Khó khăn giao tiếp và rủi ro an toàn cho công nhân.

- Phản ánh và khuếch đại tiếng ồn trên các đường phố đô thị hẹp.

Các khảo sát đô thị cho thấy các địa điểm vượt quá 90 dB có liên quan đến tỷ lệ khiếu nại cao hơn đáng kể và sự mệt mỏi của công nhân tăng lên. Trường học, bệnh viện và khu văn phòng là môi trường đặc biệt nhạy cảm nơi kiểm soát tiếng ồn là bắt buộc.

Quy định tiếng ồn toàn cầu ngày càng tăng

London, New York và Singapore đã thiết lập các quy tắc nghiêm ngặt để kiểm soát tiếng ồn xây dựng vào ban ngày. Việc không tuân thủ các quy định về tiếng ồn xây dựng dẫn đến phạt hàng ngày từ 1.000 đến 5.000 đô la. Mối đe dọa phạt thúc đẩy các nhà thầu tìm kiếm thiết bị tạo ra tiếng ồn tối thiểu. Việc sử dụng máy phá thủy lực với công nghệ giảm tiếng ồn giúp giảm khí thải nơi tiếng ồn xuất phát và ngăn chặn sự gián đoạn công việc và thanh toán phạt và khiếu nại công chúng.

Bộ phá thủy lực im lặng là gì?

Định nghĩa cơ bản

Một máy phá thủy lực im lặng (còn được gọi là búa thủy lực loại hộp) là một bộ đính kèm máy xúc được thiết kế để cung cấp năng lượng tác động mạnh mẽ trong khi giảm đáng kể tiếng ồn và rung. Nó thực hiện các nhiệm vụ phá vỡ tương tự như một bộ phá tiêu chuẩn nhưng sử dụng một nhà kín và hệ thống giảm âm tích hợp để giảm mức âm thanh trong khi hoạt động.

Nó khác biệt như thế nào với các bộ phá loại mở tiêu chuẩn

| Tính năng | Mở loại Breaker | Bộ phá im lặng (loại hộp) |

| Nhà ở | Cấu trúc lộ ra | Nhà ở thép đóng kín hoàn toàn |

| Mức độ tiếng ồn | Cao (lên đến 120-130 dB) | Giảm (thường là -10 đến -15 dB) |

| Run | Nhiều truyền đến boom / cab | Run thấp hơn thông qua miếng đệm |

| Tuân thủ đô thị | Thường khó khăn | Đáp ứng giới hạn tiếng ồn xây dựng thành phố |

| Sự thoải mái của người vận hành | Mệt mỏi cao hơn | Cải thiện đáng kể |

METDEEM’ S Loại hộp phá thủy lực DM165 và các mô hình loại hộp khác duy trì sức mạnh phá vỡ mạnh mẽ trong khi giảm tiếng ồn và rung động để đáp ứng các tiêu chuẩn xây dựng đô thị.

Cách phá tắt im lặng giảm tiếng ồn

Cấu trúc nhà ở hoàn toàn đóng cửa

Vỏ thép bảo vệ xung quanh cơ thể phá cách ly tiếng ồn tác động bên trong. Cấu trúc này ngăn chặn bức xạ âm thanh trực tiếp và giảm tiếng ồn trong không khí 10-15 dB trong điều kiện hoạt động điển hình.

Vật liệu giảm hiệu suất cao

Bên trong vỏ, METDEEM tích hợp:

- Polyurethane đệm giảm.

- Khối cách ly cao su.

- Tấm hấp thụ tiếng ồn.

Các thành phần này làm giảm rung cấu trúc và hạn chế truyền đến cánh tay máy xúc.

Bộ đệm thủy lực nội bộ và kiểm soát năng lượng

Máy ngắt METDEEM sử dụng:

- Bộ đệm dòng chảy thủy lực.

- Phục hồi năng lượng hỗ trợ tích lũy.

- Thiết kế giảm ngược.

Các hệ thống này làm mượt mà các chu kỳ tác động, các đỉnh rung thấp hơn và ổn định búa trong quá trình hoạt động liên tục - tăng cường cả độ bền và sự thoải mái.

Lợi ích của bộ phá thủy lực im lặng METDEEM

Đảm bảo tuân thủ giới hạn tiếng ồn đô thị

Các mô hình im lặng như METDEEM DM40 giúp các nhà thầu đáp ứng giới hạn tiếng ồn thành phố cho:

- Trung tâm thành phố.

- Phá phá nhà ở.

- Khu trường học.

- Bệnh viện và khu văn phòng.

Tiếng ồn thấp hơn cũng ngăn chặn phạt tốn kém và giữ cho công việc tiến bộ mà không bị gián đoạn.

Nâng cao sự thoải mái và an toàn của người điều hành

Giảm tiếng ồn và rung giúp:

- Mệt mỏi thấp hơn.

- Cải thiện giao tiếp trên trang web.

- Giảm nguy cơ tổn thương thính giác.

- Duy trì kiểm soát máy tốt hơn.

METDEEM sử dụng thép hợp kim cường độ cao và các mạch thủy lực tối ưu hóa để đảm bảo phá vỡ ổn định và hiệu quả với giảm sự phục hồi.

Quan hệ cộng đồng tốt hơn và ít khiếu nại hơn

Thiết bị tiếng ồn thấp làm giảm đáng kể sự gây nhiễu cho các ngôi nhà và doanh nghiệp xung quanh.

Điều này cải thiện:

- Chấp nhận dự án.

- Danh tiếng công cộng.

- Phối hợp với chính quyền địa phương.

- Cơ hội giành chiến thắng trong tương lai.

Máy ngắt im lặng cho phép các nhà thầu làm việc lâu hơn được phép mà không xung đột.

Ứng dụng cho METDEEM Silent Breakers

- Xây dựng đô thị và công việc nền tảng: Trong các khu vực trung tâm đông đảo, giới hạn tiếng ồn là nghiêm ngặt. Các mô hình im lặng cho phép phá vỡ đá, trench, và loại bỏ nền tảng với sự gián đoạn tối thiểu.

- Bảo trì đường và cầu: Giao thông không thể luôn được dừng lại. Bộ phá im lặng giảm thiểu sự gây rối loạn cho tài xế và người đi bộ trong khi loại bỏ nhựa, phá hủy đường và trả lại cầu

- Phá phá gần khu vực dân cư hoặc nhạy cảm: Khi làm việc gần nhà, căn hộ, trường học hoặc phòng khám, thiết bị phá phá tiếng ồn thấp là cần thiết.

Chọn đúng METDEEM Breaker

Yếu tố lựa chọn chính

Khi chọn một breaker, hãy xem xét:

- Trọng lượng hoạt động máy xúc.

- Dòng chảy thủy lực và áp suất.

- Đường kính Chisel.

- Tần số tác động.

- Độ cứng vật liệu và loại ứng dụng.

METDEEM cung cấp các mô hình cho máy xúc 0,8-49 tấn, đảm bảo khả năng tương thích với hầu hết các thương hiệu toàn cầu bao gồm CAT®, Komatsu®, Volvo®, SANY® và XCMG®.

Ví dụ phù hợp mô hình

- DM35: Đối với máy xúc 8ton, công việc đô thị nhỏ gọn.

- DM75: Đối với máy xúc 7-9ton, công trình đường bộ và phá hủy nhẹ.

- DM175: Đối với máy xúc 40-49ton, bê tông nặng và phá đá.

Mỗi mô hình trải qua thử nghiệm thủy lực nhà máy để đảm bảo hiệu suất tối ưu.

Mẹo bảo trì cho tuổi thọ lâu dài

- Mỡ thường xuyên để giảm mài mòn công cụ.

- Bảo vệ con dấu khỏi bụi và cát.

- Sử dụng phụ tùng thật sự.

- Kiểm tra bu lông, ống lót và ống thường xuyên.

- Làm sạch sau khi mưa hoặc điều kiện bùn.

- Theo dòng chảy dầu thủy lực và các khuyến nghị áp suất.

Bảo trì thích hợp làm giảm đáng kể thời gian ngừng hoạt động và làm tăng tuổi thọ của bộ phá METDEEM.

Kết luận

Máy phá thủy lực im lặng là điều cần thiết cho xây dựng đô thị hiện đại. Họ giúp các nhà thầu đáp ứng các quy định về tiếng ồn, bảo vệ công nhân và duy trì các mối quan hệ cộng đồng tích cực mà không hy sinh năng suất. METDEEM‘ Dòng máy phá im lặng cung cấp hiệu suất đáng tin cậy, giảm tiếng ồn, tăng cường an toàn và độ bền được chứng minh trên một loạt các lớp máy xúc và ứng dụng.

Câu hỏi thường gặp

Q: Điều gì làm cho một bộ phá thủy lực im lặng yên tĩnh hơn?

A: Một nhà kín hoàn toàn và hệ thống giảm bớt bên trong giảm cả tiếng ồn trong không khí và rung cấu trúc.

Q: Máy phá METDEEM có tương thích với các thương hiệu máy xúc lớn không?

A: Vâng. Máy phá METDEEM phù hợp với CAT®, Komatsu®, Volvo®, SANY®, XCMG®, và hầu hết các máy quốc tế và trong nước.

Q: Cái gì‘s thời gian bảo hành?

A: 1 năm hoặc 2.000 giờ chống lại lỗi vật liệu, thiết kế hoặc chế tạo.

Q: Bạn có cung cấp hỗ trợ sau bán hàng không?

A: Có - METDEEM cung cấp hướng dẫn lựa chọn, hỗ trợ cài đặt, khắc phục vấn đề và tùy chỉnh tùy chọn.