Les experts recommandent :

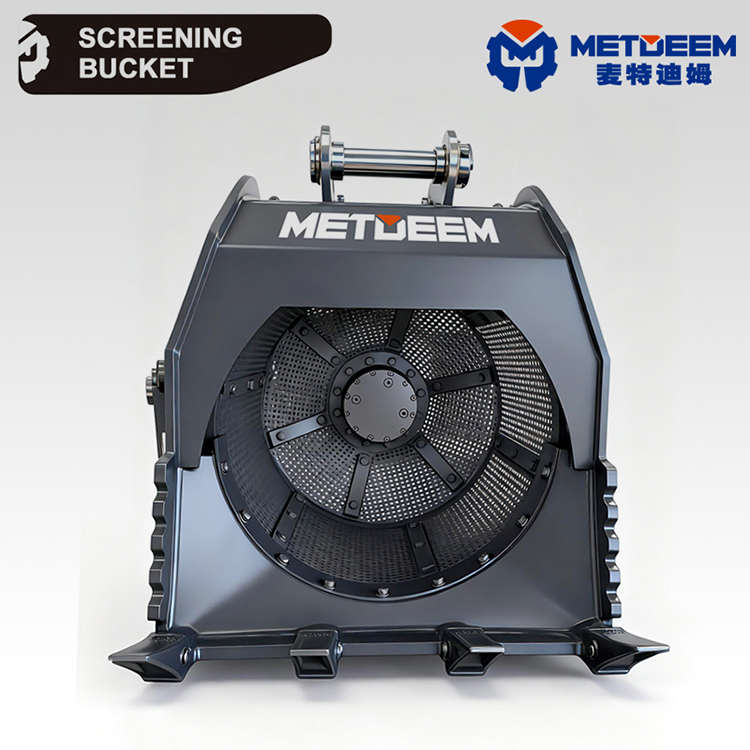

Caractéristiques principales de Metdeem Screening Bucket:

Metdeem seau de dépistage–Comment choisir METDEEM seau de filtrage hydraulique

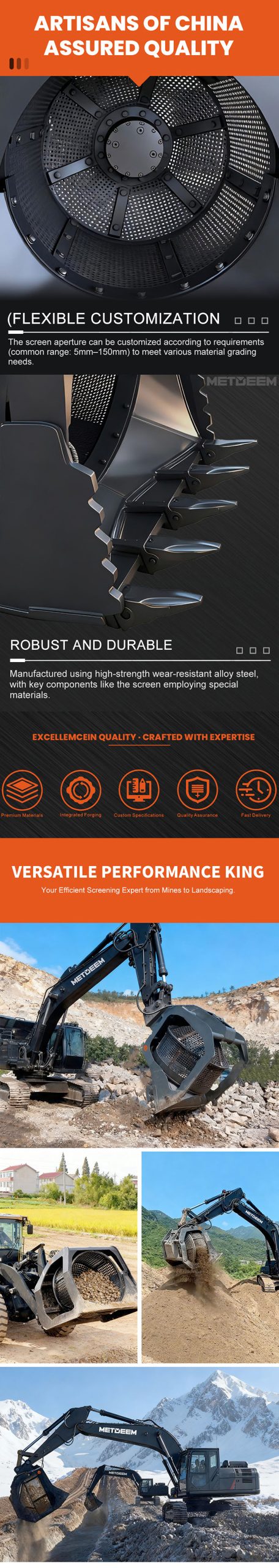

1. définir clairement le type principal de matériau à traiter, la taille maximale d'alimentation et les spécifications de décharge attendues. Ceci est la base pour choisir la taille de maille de l'écran, la configuration de la plaque de couteau et la taille du rouleau.

2.Différents modèles de seau de filtrage ont différents poids de travail et capacités de traitement. Nous devons choisir un modèle qui correspond au tonnage de l'excavatrice peut garantir que l'excavatrice peut transporter des charges en toute sécurité. Et il est nécessaire de vérifier si le débit hydraulique et la pression de l'excavatrice répondent aux exigences du moteur hydraulique du seau de tamisage pour s'assurer que le tambour peut rouler à la vitesse et au couple optimaux.

3. Ensuite, la qualité de configuration de la plaque de couteau devrait être sélectionnée en fonction de la nécessité d'un écrasement puissant simultané. En même temps, en fonction des exigences d'efficacité de traitement du projet et en combinaison avec le temps de cycle de travail de votre pelle, sélectionnez la taille appropriée du modèle de rouleau. Les modèles avec une capacité de traitement trop faible réduiront l'efficacité du travail, tandis que ceux avec une capacité trop grande peuvent provoquer des gaspillages d'énergie et le ralentissement de l'équipement.

4.Finalement, il est nécessaire de confirmer si le diamètre de l'arbre, l'engrenage d'ouverture, la distance centrale, etc. de l'interface de connexion du seau de tamisage sont compatibles avec votre bras d'excavatrice. Si une commutation fréquente entre différents dispositifs ou accessoires est nécessaire, un système à changement rapide est un choix nécessaire pour améliorer l'efficacité.

| Article/modèle | Unité | DM-400 | DM-800 | DM-1200 | DM-1500 | DM-2500 |

| Sécran tambour Diamètre | Mm | 720 | 930 | 1160 | 1500 | 1700 |

| Configurer la pression | Le bar | 130 | 170 | 170 | 170 | 170 |

| Volume du cylindre | L/min | 20 | 75 | 120 | 120 | 120 |

| Capacité | m² | 0.40 | 0.80 | 1.20 | 1.50 | 2.50 |

| Dimensions | Mm | 1200×800×1200 | 1650 × 1100 × 1500 | 2050 × 1350 × 1850 | 2050 × 1650 × 2350 | 2400×1900×2500 |

| Poids | Kg | 450 | 950 | 1800 | 2200 | 3000 |

| Excavatrice appropriée | Tonne | 5.5-10 | 10-18 | 18-24 | 18-35 | 30-38 |

♥ Les spécifications de cet équipement sont sujettes à modification pour des améliorations.

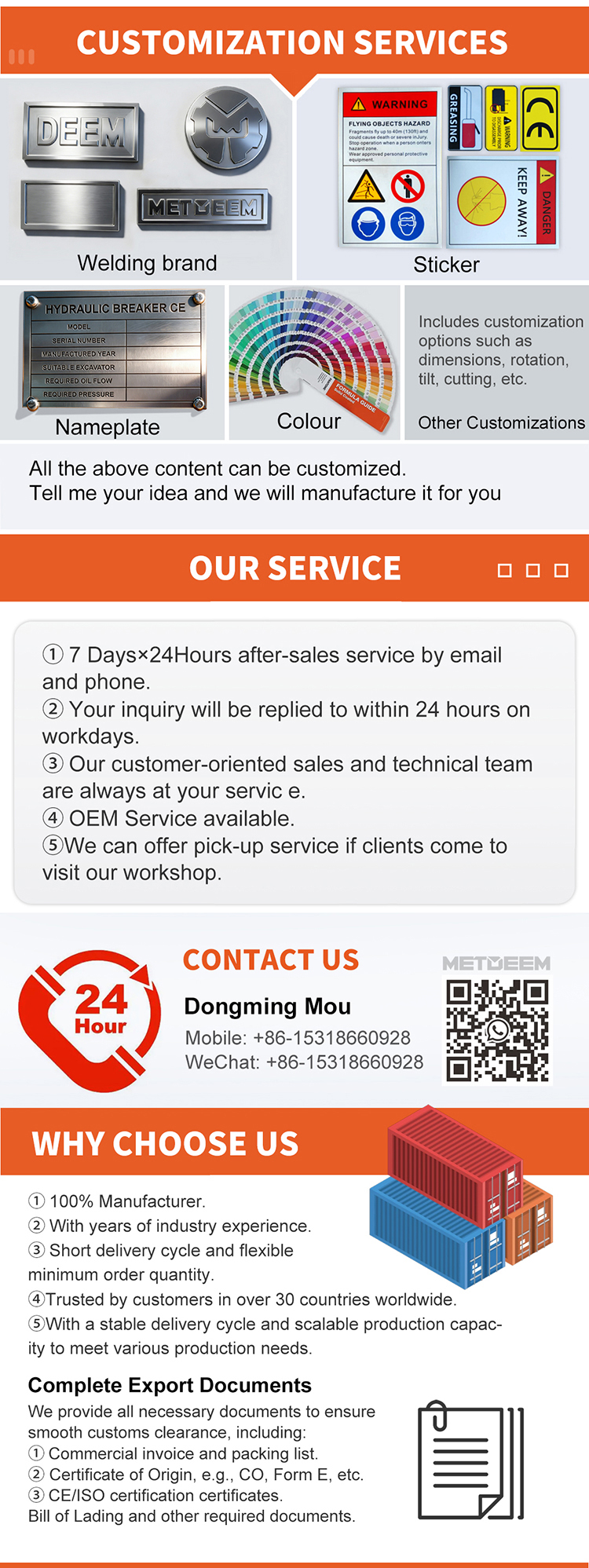

Nos services-Internationalisé

garantie

1.Metdeem seau de concasseur de roche bénéficie d'une période internationale de garantie de qualité de 12 mois (à compter de la date de départ du port), et ses composants structurels de base et son système de transmission hydraulique sont couverts par des garanties de qualité clés.

2.METDEEM a des centres dans le monde entier, garantissant que les pièces détachées clés et les pièces détachées régulières peuvent être livrées dans le monde entier dans les 7 jours ouvrables.

3.METDEEM offre des services de support technique, permettant le diagnostic de défaut en ligne et l'orientation opérationnelle par des experts.

4.METDEEM promet de fournir une garantie d'approvisionnement continu de pièces détachées pendant plus d'un an et peut offrir des services d'optimisation et d'amélioration des performances des équipements pour s'assurer que votre équipement reste dans le meilleur état de travail.

Yantai Hansheng Heavy Industry Co., Ltd.

Support technique: Beijing Xinhulian Technology Co., Ltd.