قائمة

إغلاق

يوصي الخبراء بما يلي:

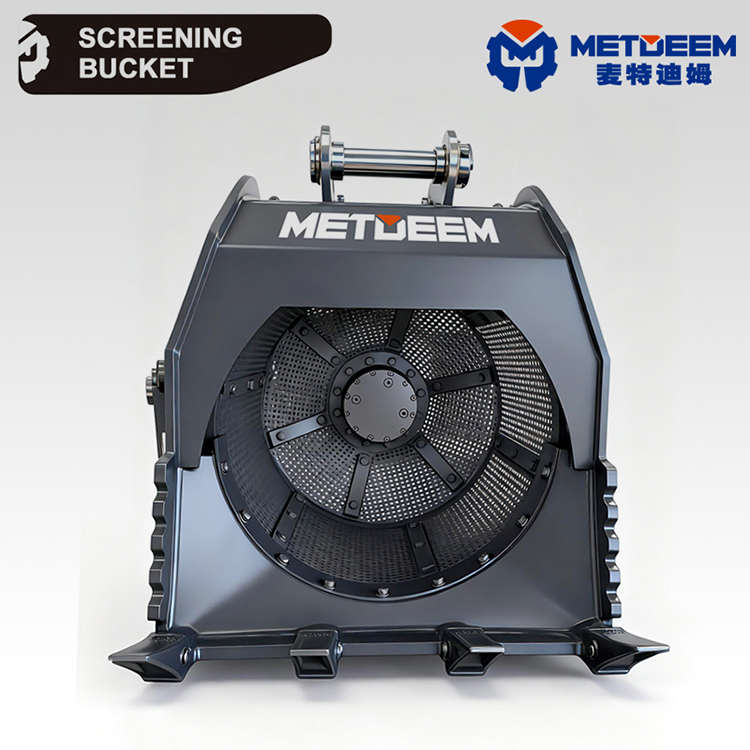

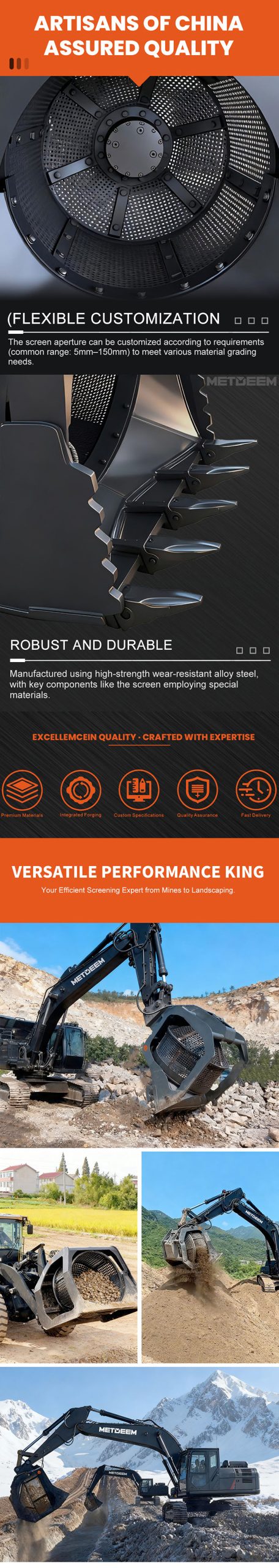

الميزات الرئيسية لدلو فحص Metdeem:

دلو فحص Metdeem–كيفية اختيار دلو الفحص الهيدروليكي METDEEM

1. تحديد بوضوح النوع الرئيسي من المواد التي سيتم معالجتها ، والحجم الأقصى للتغذية ، ومواصفات التفريغ المتوقعة. هذا هو الأساس لاختيار حجم شبكة الشاشة وتكوين لوحة السكين وحجم الأسطوانة.

2. نماذج مختلفة من دلاء الفحص لها أوزان عمل مختلفة وقدرات معالجة. علينا اختيار نموذج يتطابق مع حجم الحفارة يمكن أن تضمن أن الحفارة يمكن أن تحمل الأحمال بأمان. ومن الضروري التحقق من ما إذا كان التدفق الهيدروليكي والضغط للحفارة يلبي متطلبات المحرك الهيدروليكي لدلو الفحص لضمان أن الطبل يمكن أن يتداول بسرعة ودور الدوران الأمثل.

3. بعد ذلك ، يجب اختيار درجة تكوين لوحة السكين بناءً على ما إذا كان هناك حاجة إلى سحق قوي متزامن. في نفس الوقت ، بناءً على متطلبات كفاءة المعالجة للمشروع وبالتركيب مع وقت دورة العمل للحفارة الخاصة بك ، حدد الحجم المناسب لنموذج الأسطوانة. النماذج التي لديها قدرة معالجة صغيرة جدا سوف تقلل من كفاءة العمل، في حين أن تلك التي لديها قدرة كبيرة جدا قد تسبب هدر الطاقة وتعطل المعدات.

4. أخيرا ، من الضروري تأكيد ما إذا كان قطر العمود ، والعتاد المفتوح ، والمسافة المركزية ، إلخ. من واجهة الاتصال لدلو الفحص متوافقة مع ذراع الحفار الخاص بك. إذا كان هناك حاجة إلى التبديل المتكرر بين الأجهزة المختلفة أو المرفقات ، فإن نظام التغيير السريع هو خيار ضروري لزيادة الكفاءة.

| البند / النموذج | وحدة | DM - 400 | DM - 800 | DM - 1200 | DM - 1500 | DM - 2500 |

| Sكرين طبل قطر | مم | 720 | 930 | 1160 | 1500 | 1700 |

| إعداد الضغط | بار | 130 | 170 | 170 | 170 | 170 |

| حجم الأسطوانة | لتر / دقيقة | 20 | 75 | 120 | 120 | 120 |

| القدرة | م2 | 0.40 | 0.80 | 1.20 | 1.50 | 2.50 |

| الأبعاد | مم | 1200 * 800 * 1200 | 1650 × 1100 × 1500 | 2050 * 1350 * 1850 | 2050 * 1650 * 2350 | 2400 * 1900 * 2500 |

| الوزن | كيلوغرام | 450 | 950 | 1800 | 2200 | 3000 |

| حفارة مناسبة | طن | 5.5-10 | 10-18 | 18-24 | 18-35 | 30-38 |

♥ تخضع مواصفات هذه المعدات للتغيير من أجل التحسينات.

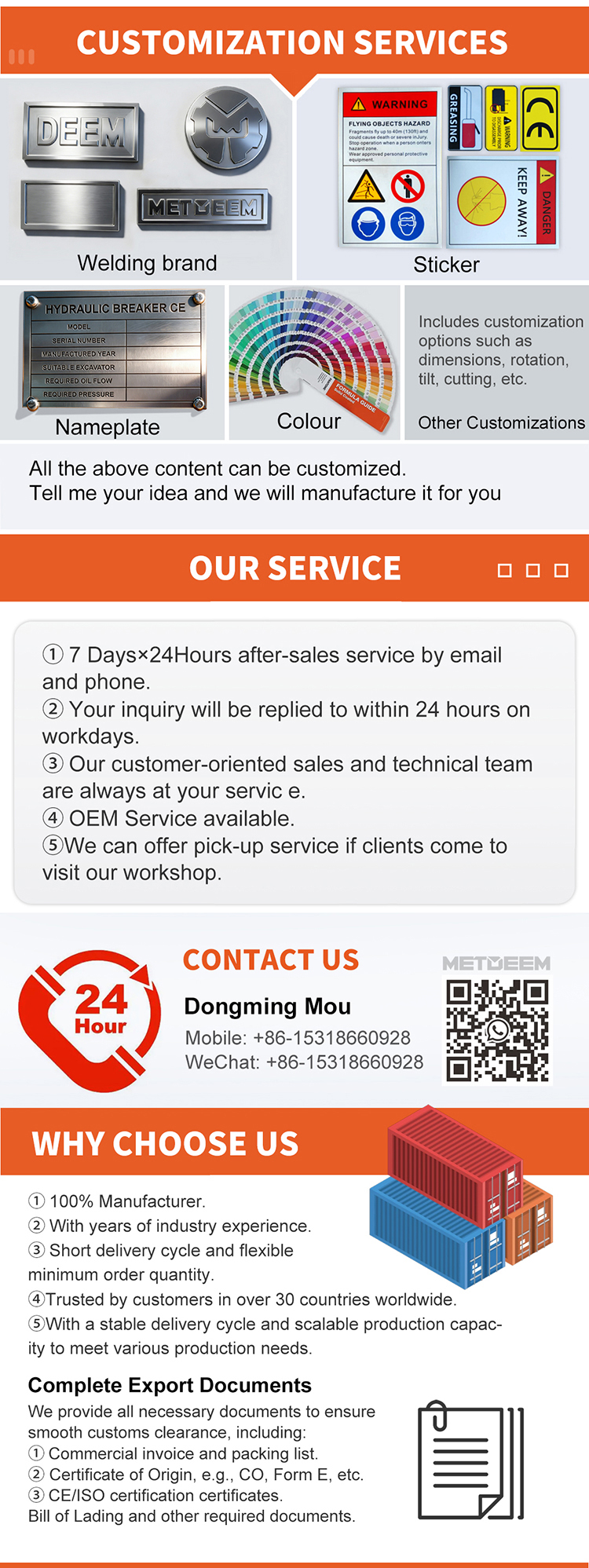

خدماتناتدويل

الضمان

1.Metdeem صخرة كسارة دلو تتمتع بفترة ضمان الجودة الدولية لمدة 12 شهرا (اعتبارا من تاريخ المغادرة من الميناء) ، وتغطي مكوناتها الهيكلية الأساسية ونظام النقل الهيدروليكي بضمانات الجودة الرئيسية.

2.METDEEM لديها مراكز في جميع أنحاء العالم، وضمان أن قطع الغيار الرئيسية وقطع الغيار العادية يمكن تسليمها عالميا في غضون 7 أيام عمل.

3. تقدم METDEEM خدمات الدعم التقني ، مما يتيح تشخيص الأخطاء عبر الإنترنت وتوجيه التشغيل من قبل الخبراء.

4.METDEEM تعهد بتوفير ضمان توريد قطع الغيار المستمر لأكثر من سنة واحدة ويمكن أن تقدم خدمات تحسين أداء المعدات والترقية لضمان أن تبقى معداتك في أفضل حالة عمل.

يانتاي هانشينغ الصناعة الثقيلة المحدودة

الدعم التقني: بكين Xinhulian التكنولوجيا المحدودة