Wichtigkeit der richtigen Breaker Auswahl

Die Auswahl des richtigen Hydraulikbrechers für einen Bagger spielt eine entscheidende Rolle bei der Erzielung starker Maschinenleistung und Projektergebnisse. Wenn Sie einen Breaker gut paaren, erhöht es die Energieflusseffizienz. Es reduziert auch die Belastung auf den Bagger und das Werkzeug selbst. Außerdem hilft es, unerwartete Stopps zu vermeiden. Ein gutes Match erhöht die Arbeitsgeschwindigkeit und senkt den Verschleiß am Getriebe. Eine schlechte Wahl hingegen führt zu schwacher Leistung, regelmäßigen Ausfällen und höheren Reparaturrechnungen.

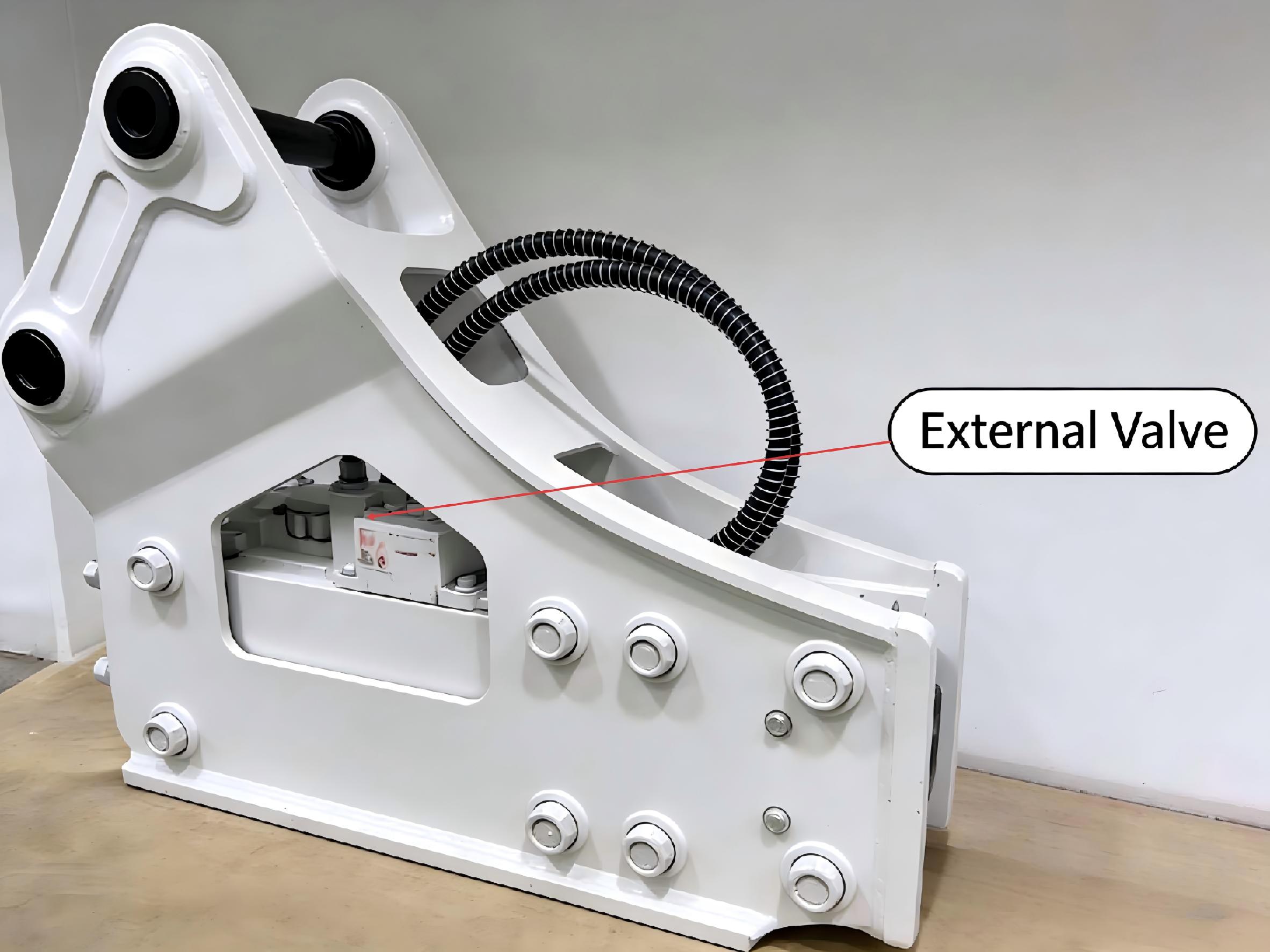

Verständnis von externen Ventilhydraulischen Breakers

Hydraulische Unterbrecher variieren in den Ventilausrüstungen, und externe Ventilversionen bieten klare Vorteile. Diese Systeme sitzen außerhalb des Hauptzylinders. Diese Einrichtung ermöglicht eine einfachere Montage in verschiedene Maschinen. Externe Ventilbrecher passen sich gut an verschiedene Bagger an. METDEEM steht als vertrauenswürdiger Name in Baumaschinen und Bauteilen. Wir konzentrieren uns auf die Herstellung dieser Breaker mit starker Leistung und dauerhafter Bauqualität.

Baggertonnage und Breaker Kompatibilität

Klassifizierung von Baggern nach Gewichtsbereich

Bagger werden in der Regel in drei Kategorien basierend auf dem Betriebsgewicht eingeteilt. Leichter Typ von 0,8 bis 15 Tonnen, mittlerer Typ von 15 bis 35 Tonnen und schwerer Typ von 35 bis 100 Tonnen oder mehr. Jede Gruppe benötigt einen Schalter, der zu ihrer Hydraulikleistung passt. Die Brecher müssen den Kraft- und Ölflussbedarf der Maschine entsprechen. Für kleine Maschinen benötigen Sie kleine, präzise Werkzeuge. Größere erfordern harte, leistungsstarke Ausrüstung.

Passend METDEEM Breaker an Baggergröße

METDEEM bietet viele Optionen für diese Gewichtsgruppen. Nehmen Sie zum Beispiel den DM35 - er arbeitet mit 0,8 Tonnen Baggern und verwendet einen 35mm Meißel. Dann gibt es’ s die DM100für 11 bis 16 Tonnen Maschinen mit einem 100mm Meißel. METDEEM gestaltet seine Modelle für bestimmte Gewichtsbereiche. Diese Einrichtung ermöglicht einen reibungslosen Energietransfer. Es liefert maximalen Aufprall, ohne den Bagger zu schieben’ Die Hydraulik ist zu hart.

Arbeitstyp und Strategie zur Auswahl von Breakers

Trenching Anwendungen: Präzision Trenching Arbeit

Bei Grabenarbeiten benötigen Arbeiter Genauigkeit und wenige Störungen für den nahe gelegenen Boden. Die kleineren bis mittleren Brecher von METDEEM leisten hier am besten. Diese Einheiten bieten eine konstante Schlagkraft mit Optionen zur Einstellung der Geschwindigkeit. Sie eignen sich für Aufgaben wie das Graben von Versorgungsleitungen, Entwässerungswegen oder enge Stellen. Die leichten bis mittleren Trenner von METDEEM bewältigen schmale Trennaufgaben reibungslos.

Sekundärer Bruch in Steinbrüchen

Steinbrucharbeiten, die große Steine zerbrechen, erfordern eine starke Schlagkraft. Die schweren hydraulischen Steinhämmer von METDEEM werden mit festen Meißeln und Akkumulatoren zur Handhabung von Stößen ausgestattet. Sie halten sich unter ständiger schwerer Verwendung gut aus. Dies macht sie ideal für das Spalten von Steinen nach dem ersten Schnitt.

Bergbaubetrieb: Bergbaubrecher

Bergbaustellen verlangen zuverlässige Werkzeuge, die ohne Pausen laufen. Die Bergbaubrecher von METDEEM, beginnend mit den DM165 und größer, verwenden härtere Teile und sind für laufende Arbeiten gebaut. METDEEM Bergbaubrecher enthalten extra starke Elemente für raue Stellen. Ihre hochwertigen Legierungen und sorgfältige Bearbeitung helfen ihnen, unter schwierigen Bedingungen zu halten. Zum Beispiel in einer typischen Kohlemine können diese Brecher 12-stündige Schichten verarbeiten, die Erz brechen und ihre Ausdauer durch reale Feldtests zeigen.

Verständnis der Vorteile des externen Ventilsystems

Wie externe Ventile die Kompatibilität verbessern

Die externe Ventilanordnung trennt die hydraulische Steuerung vom Hauptsystem des Baggers. Es trennt das Steuerventil des Schalters vom Hauptzylinder, wodurch die Abhängigkeit von der internen Ventilkonfiguration des Baggers verringert wird. Dies reduziert Probleme zwischen verschiedenen Baggertypen und verhindert Druckaufbau, der die Grundeinheit schädigen könnte.

Anpassung an verschiedene Baggerhydrauliksysteme

Schalter mit Außenventilen von METDEEM vereinfachen die Einrichtung vieler Maschinentypen, von älteren bis hin zu frischen mit elektronischer Steuerung. Es erleichtert den Prozess für frühere und aktuelle Baggerstile. Diese Flexibilität erhöht die Sicherheit, verkürzt die Installationszeit und eröffnet mehr Einsatzmöglichkeiten. In der Praxis kann ein Auftragnehmer den gleichen Schalter zwischen verschiedenen Versionen mit minimalen Anpassungen an Schläuchen oder Druckeinstellungen wechseln.

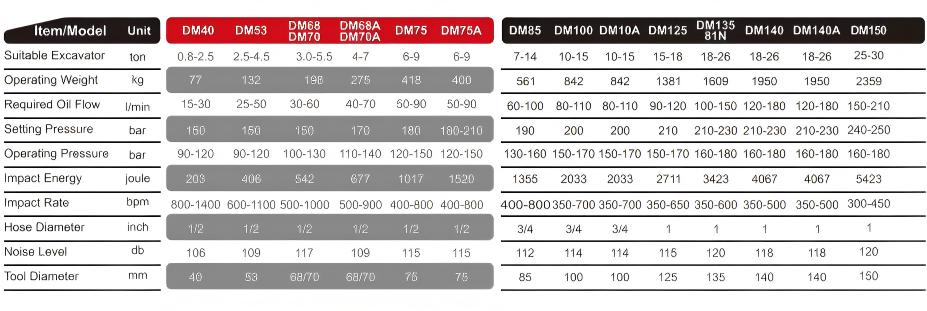

Auswahl des richtigen METDEEM-Breaker-Modells

Um einen Brecher richtig zu dimensionieren, überprüfen Sie Details wie das Gewicht des Baggers, die Ölströmungsmenge, das Druckniveau und die Meißelgröße. Die DM53Zum einen läuft es mit einem Durchfluss von 25 bis 50 L/min und einem Arbeitsdruck von 120–150 bar (12–15 MPa). Achten Sie immer auf Betriebsgewicht, Öldurchflussrate, Arbeitsdruck und Werkzeugdurchmesser. Nutzen Sie unsere Produktspezifikationen für die beste Passform. Branchenprofis beginnen oft mit der Durchflussrate - sagen Sie, wenn Ihr Bagger 30 L / min drückt, wählen Sie einen Schalter in diesem Bereich aus, um Fehler zu vermeiden.

Übersicht über die METDEEM Hydraulikbrecher

Hydraulische Breaker Eigenschaften Übersicht

Unsere Hydraulikbrecher verwenden eine flexible Konstruktion mit starken Außenschalen und reduzierter Rückstößwirkung. Sie verfügen über eine modulare Konstruktion, verstärktes Gehäuse und einen geringen Rückschlagbetrieb. METDEEM wendet das exakte CNC-Schleifen für eine enge Ausrichtung in Zylinder und Kolben an. Dies hält die Aufprallenergie stabil. Diese Präzision hilft aus jahrelangem Feldfeedback bei Arbeiten wie städtischen Abriss, bei denen sogar Schläge ungleichmäßigen Verschleiß verhindern.

Anwendungsbasierte Modellaufteilung

- Lichttyp: Modelle wie DM40 eignen sich gut für Graben- und Grundversorgungsarbeiten.

- Mittlerer Typ: Wahlmöglichkeiten wie DM155 passen zum täglichen Bau- und Straßenarbeit.

- Schwerer Typ: Heavy-Duty-Modelle wie der DM 230 Anzug Bergbau- und Steinbruchstätten.

Die Hydraulikbrecher der METDEEM Soosan- und Furukawa-Serie werden von weltweiten Kunden wegen ihrer hohen Leistung in Bezug auf Sicherheit und Haltbarkeit anerkannt.

Optimierung der Betriebseffizienz durch richtige Abpassung

Verringerung der Ausfallzeiten durch korrekte Kopplung

Ein großer Schalter begrenzt Flüssigkeitslecks im Inneren, stoppt überschüssige Wärme und verlängert die Lebensdauer. Die richtige Trenngröße reduziert Überhitzung und hydraulische Belastung. Dadurch sehen Sie im Laufe der Zeit weniger Fixes und geringere Kosten.

Steigerung der Leistung an anspruchsvollen Arbeitsplätzen

Wenn Sie einen Breaker richtig passen, gibt es zuverlässige Leistung pro Hit. Dies erhöht die Arbeitsgeschwindigkeit, insbesondere bei wiederholten Aufgaben wie dem Zerbrechen von Beton oder dem Rissen von Steinen. Passende Aufstellungen sorgen für eine konstante Schlaganergie. Unsere Schalter verwenden langlebige Materialien wie 20CrMo-Zylinder und 40CrNiMo-Kolben, um eine starke Leistung mit wenig Ausfall zu erhalten. Betreiber in Steinbruchsystemen haben bemerkbare Produktivitätsverbesserungen gemeldet, wenn die Spezifikationen der Unterbrecher richtig abgestimmt werden, wenn die Paarungen den Spezifikationen entsprechen.

Schlussfolgerung

Die Auswahl des besten Außenventilhydraulikbrechers ist sehr wichtig für die maximale Arbeitsleistung, während das Getriebe sicher ist. Denken Sie an Elemente wie Baggergewicht, Aufgabentyp - vom Graben bis zum Bergbau - und hydraulische Passform. Auf diese Weise können Sie es richtig mit den Hydraulikbrechern von METDEEM kombinieren. Intelligente Wahlen erhöhen nicht nur die tägliche Effizienz, sondern verlängern auch die Lebensdauer des Breakers und der Hauptmaschine. Letztendlich bringen sie soliden Wert in harten Arbeitsbedingungen.

FAQ (häufig gestellte Fragen)

F: Wie bestimme ich die richtige Größe des Hydraulikbrechers für meinen Bagger?

A: Passen Sie das Betriebsgewicht, den Ölfluss und die Druckanforderungen des Brechers an die Spezifikationen Ihres Baggers und verweisen Sie auf den Modellleitfaden von METDEEM.

F: Sind externe Ventilbrecher mit allen Baggern kompatibel?

A: Ja, METDEEM Furukawa Serie externe Ventilsysteme sind entwickelt, um über Bagger von 6T bis 100T durch Isolierung der Steuerung von der internen Hydraulik der Hauptmaschine zu arbeiten.

F: Was macht METDEEM-Bergbaubrecher für den schweren Einsatz zuverlässig?

A: Sie verfügen über verbesserte strukturelle Verstärkung, optimierte Kühlsysteme und Komponenten, die kontinuierlichen starken Einschlägen standhalten.

F: Kann ich einen größeren Breaker auf einem kleineren Bagger für mehr Leistung verwenden?

A: Nein, überdimensioniert kann hydraulische Überlastungen oder strukturelle Schäden verursachen; immer auf der Grundlage von Herstellerlichtlinien wie die von METDEEM passen.