More powerful, with a strong working drive

The tonnage is moderate and the application range is wide.

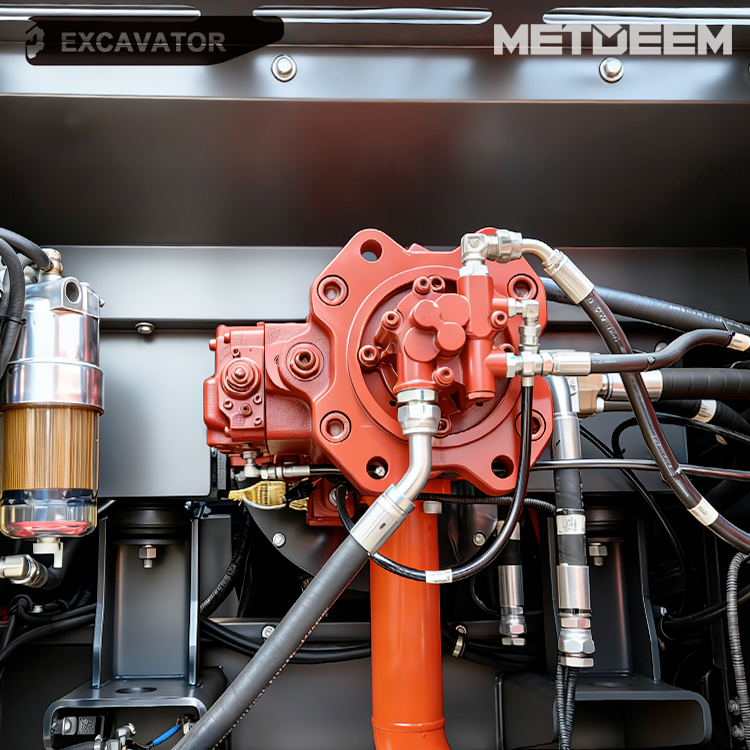

The core components are solid and can withstand heavy loads.

Can be configured according to your requirements

Main Performance and Dimensions

System Details and Optional Configurations

Regarding the manufacturer

Yantai Hansheng Heavy Industry Co., Ltd.

Technical support: Beijing Xinhulian Technology Co., Ltd