Product Overview: Defining a New Standard of Durability and Efficiency

METDEEM hydraulic breakers are professional hydraulic attachments designed for demanding working conditions worldwide. We deeply integrate advanced engineering mechanics, rigorous manufacturing processes, and a profound understanding of end-user needs to provide products with significant advantages in durability, impact efficiency, and overall operating costs. Through collaboration and supporting experience with leading global construction machinery manufacturers such as CAT®, Sany®, XCMG®, LiuGong®, Sunward Intelligent®, and Kubota®, we ensure that every breaker is perfectly matched with its host machine, becoming a key force in improving productivity in diverse scenarios such as mining, demolition, road breaking, and tunnel excavation.

Exquisite Manufacturing Process: Durable Guarantee from Shell to Details

Superior products begin with rigorous control over manufacturing details. Every component of a METDEEM hydraulic breaker is precision-designed and machined to ensure both external robustness and internal reliability.

Shell Structure Design and Processing

- Mechanical Optimization Design: The shell serves as a load-bearing structure that efficiently transmits and absorbs impact forces during operation.We employ a professionally and systematically optimized structural design, making reasonable use of high-strength sheet metal to ensure the shell shape fully conforms to the dynamic force-bearing principle of a hydraulic breaker, effectively dispersing stress and avoiding localized fatigue.

- Precision Laser Cutting: All sheet metal is made of high-quality steel and cut using high-precision laser cutting technology. This process ensures precise, smooth edges on parts, preventing warping and stress-induced deformation, which are common issues with traditional cutting methods that can compromise part integrity.It lays a solid foundation for subsequent welding and assembly, thereby guaranteeing the overall dimensional stability and long-term structural integrity of the shell.

Stringent Assembly and Surface Treatment Standards

- Systematic Assembly Process

Our assembly process follows strict Standard Operating Procedures (SOPs) and employs a three-step inspection process: initial self-inspection, peer review inspection, and final specialist inspection, ensuring comprehensive accuracy at each stage, from valve block installation and pipeline connection to final assembly and commissioning, making the product 100% compliant with factory performance standards.

- Seamless Transfer and Surface Protection

All workpieces are isolated and protected with elastic rubber pads during processing and transfer, eliminating surface damage and minor deformation caused by impacts. The finished shell surface is smooth and flat, without any flaws.

- Multi-layer Coating Protection System

- First Layer: Epoxy Primer. Provides excellent rust prevention and adhesion, protecting the steel plate from environmental corrosion.

- Second Layer: Intermediate Bonding Coat. Enhances adhesion between coatings, ensuring the topcoat remains durable and does not peel off.

- Third Layer: Polyurethane Topcoat. Provides a vibrant, wear-resistant, and weather-resistant final appearance.

These three layers not only build a strong physical and chemical protective barrier but also give the product a professional and reliable overall visual image.

- Pre-protection of Critical Components

To address potential rust issues caused by long-term sea transport or storage, we apply a specialized anti-rust barrier coating to all exposed pins, ensuring that critical connecting components are still in optimal condition and ready for direct installation and use when the product arrives in the customer’s hands.

Core Technology and Intrinsic Quality: The Source of Lasting Performance

The superior performance of METDEEM hydraulic breakers is rooted in continuous investment in core materials and internal technologies.

Superior Materials and Heat Treatment Processes

- High-Standard Special Steel: All core components subjected to high-impact loads, such as pistons, cylinders, and front bushings, are made from high-strength alloy steel, ensuring superior impact resistance and longevity. High-quality materials are fundamental to ensuring high impact force, extended maintenance intervals, and ultimate service life.

- Advanced Molecular-Level Strengthening Treatment: Through our proprietary heat treatment and surface hardening technology, internal stress-bearing components undergo deep processing. This process alters the molecular structure of the metal surface, making its bonding denser and significantly improving the fatigue strength, wear resistance, and impact resistance of the components. Core components treated in this way are designed to have a service life of over 5 years, greatly reducing long-term maintenance costs.

Optimized Internal Structure and Hydraulic Circuit Design

- High-Efficiency Impact Performance: Under the same host hydraulic pressure and flow input, METDEEM hydraulic breakers can generate greater single-stroke impact force and a faster continuous impact frequency. This is thanks to our optimized internal hydraulic circuit design, which eliminates unnecessary flow bottlenecks and significantly reduces leakage losses of high-pressure oil between internal cavities, allowing hydraulic energy to be converted into impact mechanical energy more efficiently.

- Energy Efficiency: Thanks to precision internal fittings and minimal leakage, our hydraulic breakers achieve superior impact force and operational efficiency with reduced hydraulic pressure and flow, resulting in lower fuel consumption and optimal energy usage, thereby reducing the load on the excavator’s main pump and achieving significant fuel savings.

- Increased Efficiency and Reduced Costs: Greater impact force and faster frequency directly translate into higher work efficiency and shorter project durations. At the same time, less internal wear means lower component wear rates, significantly reducing the overall operating and maintenance costs of the equipment in the long run.

Comprehensive Product Configuration and Worry-Free After-Sales Service

We are committed to providing complete, out-of-the-box solutions and a reliable global support network.

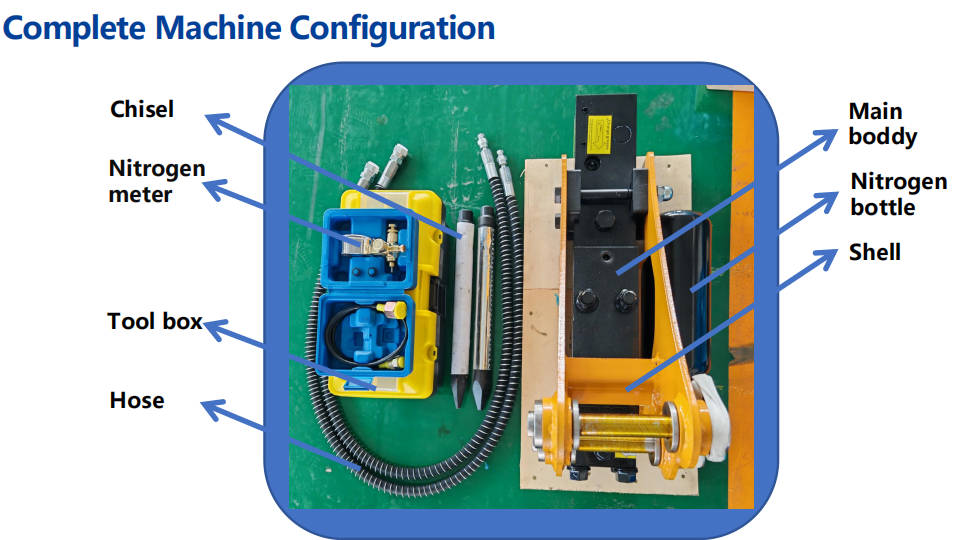

Standard Factory Configuration

To facilitate immediate deployment and subsequent maintenance, each METDEEM hydraulic breaker comes standard with:

- Dual chisel configuration: Two standard chisels are included with the breaker, and different cutting edge types, such as straight, cross, conical, or large-head chisels, can be selected depending on the specific material being broken (e.g., asphalt, concrete, rock).

- Dedicated tool kit: Contains specialized tools for installation and maintenance, facilitating on-site chisel installation and basic maintenance.

- Pressure testing and inflation kit: Includes a nitrogen pressure gauge for accurate monitoring and adjustment of nitrogen pressure in the rear cylinder accumulator, and a portable high-pressure nitrogen cylinder for on-site nitrogen replenishment.

- Complete hydraulic piping: Two high-quality hydraulic hoses are provided to connect the breaker to the excavator’s inlet and return hydraulic lines, ensuring quick and safe connection.

High Interchangeability and Ease of Maintenance

We deeply understand the importance of continuous equipment operation. METDEEM hydraulic breakers adhere to a high standard of design. For the same product model (e.g., the DM68 series), all internal wear parts (such as inner and outer bushings, seals) and external accessories are standard parts, ensuring complete interchangeability. When components such as chisels and bushings wear down after prolonged use, customers can easily purchase universal standard parts for replacement, quickly restoring equipment performance without worrying about parts downtime or customization cycles, maximizing equipment uptime.

Global After-Sales Support Commitment

Our products are sold to over 20 countries and regions worldwide. We commit to:

- 24-hour response mechanism: Regardless of the customer’s location, our technical support team will provide a clear solution or guidance within 24 hours of receiving feedback on a problem.

- Remote and on-site support: Our engineers can assist in troubleshooting remotely. If the problem is indeed due to product quality, we promise to directly replace the customer with a brand new part or product, ensuring that the customer’s downtime losses are minimized.

Company Philosophy: Making the World Trust Made in China

“Making the world fall in love with Made in China” is not only our slogan, but also our guiding principle. Through continuous technological innovation, lean manufacturing, and cost optimization, we offer high-quality hydraulic breakers at competitive prices, enabling construction workers worldwide to use reliable and efficient METDEEM equipment. We are proud of this and continue to contribute our expertise to global infrastructure development.

FAQ

Q: What are the core advantages of METDEEM hydraulic breakers compared to other brands?

A: The core advantage lies in achieving greater impact force and faster frequency with the same hydraulic input through optimized internal hydraulic circuits and precision manufacturing, while also possessing high parts interchangeability and a highly competitive price-performance ratio.

Q: Are your spare parts easy to purchase and replace?

A: Yes, our products feature a highly standardized design. All wear parts for the same model are universal standard parts. Our comprehensive global supply network ensures convenient replacement and maximizes equipment uptime.

Q: Are our products compatible with mainstream excavator brands on the market?

A: Fully compatible. We have experience working with several major OEMs such as CAT®, Sany®, and XCMG®, providing complete models and installation solutions for excavators of various tonnages.

Q: How is after-sales service guaranteed, especially overseas?

A: We promise 24-hour problem response for customers worldwide and provide remote technical support. In the event of genuine product defects, we ensure a swift replacement process, offering new parts to minimize downtime and ensure uninterrupted service.

Q: What key components are included as standard with purchase?

A: Each hydraulic breaker comes standard with two chisels, a dedicated toolbox, a nitrogen pressure gauge, a nitrogen cylinder, and a complete set of hydraulic hoses for connecting to the excavator, ensuring it is ready for immediate installation and use.