Soil compaction is a construction foundation process with a direct influence on structural stability and longevity, such as roads, foundations, and pipelines. Ineffective performance means costly failures—cracking, shifting, and seepage. A familiarity with common problems and how to correct them can save time, reduce risks, and ensure successful projects.

Lack of Adequate Soil Compaction

Causes of Inadequate Compaction

- Inadequate equipment for the soil type

- Incorrect levels of moisture (too dry or too wet)

- Too thick compacting layers

- Insufficient passes with a compactor or improper speed

Signs to Look For

- Settlement is visible after compaction

- Water standing on the surface after precipitation

- The equipment is making deep ruts

How to Solve It

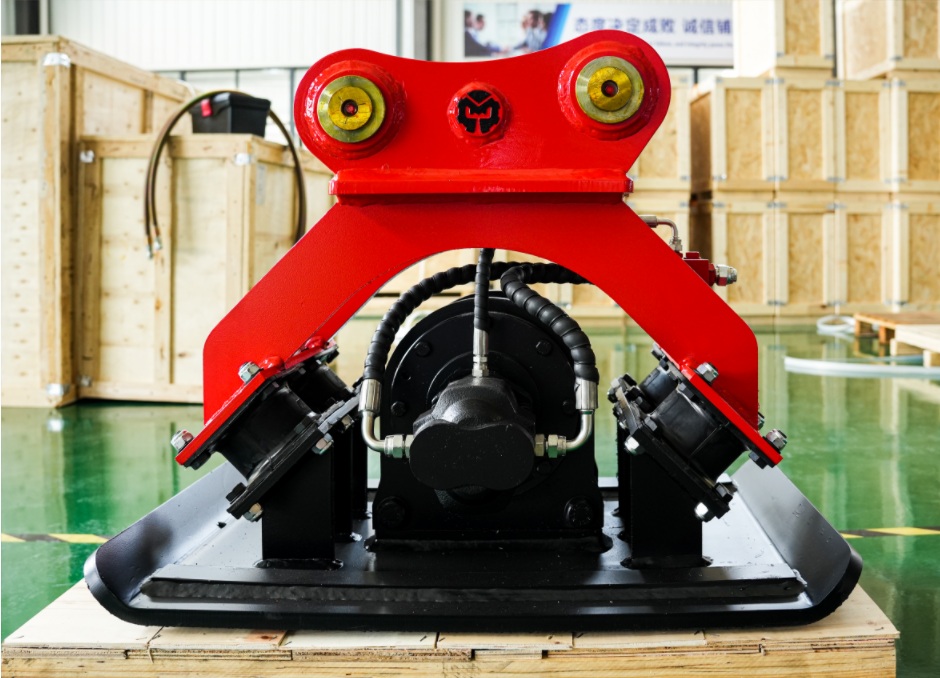

Select the appropriate equipment for your specific type of soil. For the granular type, vibratory compactors are ideal. METDEEM DM08 Compactor offers firm vibration ideal for such a material and guarantees good densification. Test and adjust to optimum moisture content before compaction and compact in thin, even lifts to maintain uniform density.

Overcompacted Soil Problems

Causes of Overcompaction in the Field

- Too many compactor passes

- Too much force for the soil type

- Incorrect vibration frequency settings

Signs to Look For

- Surface cracking or crusting

- The equipment bounces when it is being used

- Reduced soil permeability

Avoiding Overcompaction

Prevent the overcompaction of soil by monitoring compactor passes closely and utilizing real-time feedback systems where available. Operators should be trained not just in compacting but also in when to stop as well. Using equipment like METDEEM’s DM08 Compactor, which allows for constant vibration without too much downward pressure, maintains a balance between efficient densification and avoiding harm.

Also, compensating hydraulic settings for changing soils reduces unwanted application of energy—this prevents crushing of particles in granular soils or excessive development of pore pressures in clays.

Irregular Soil Settlement After Compaction

Causes of Irregular Settlement

- Various kinds of soil on the site

- Random compaction patterns

- Poor surface preparation before compaction

- Tight corners and slopes are absent

What to Seek Out

- Differential settling after construction

- Evident low spots or ridges

- Cracking of finished surfaces

Steps to Achieve Uniform Compaction

Uniformity may be enhanced through the use of attachments that increase precision grading and surface preparation prior to compaction initiation. The METDEEM tilt bucket is quite ideal for leveling and grading earthwork. It has a tilting of 45 degrees in either direction. Manipulate this excavator attachment obliquely to the exact angle needed, such that you are more effective in the handling of work. This helps create even surfaces on uneven terrains before sending out compactors. The utilization of GPS-guided systems or laser levels during grading also ensures precision before rolling out compactors like METDEEM’s DM08 compact.

Equipment-Related Performance Problems

Common Problems

- Worn-out components or improper maintenance

- Defects in hydraulic systems

- Misfunctioning of operating settings

- Equipment that is unsuitable for the soil type

Proper Usage of METDEEM Compacting Equipment

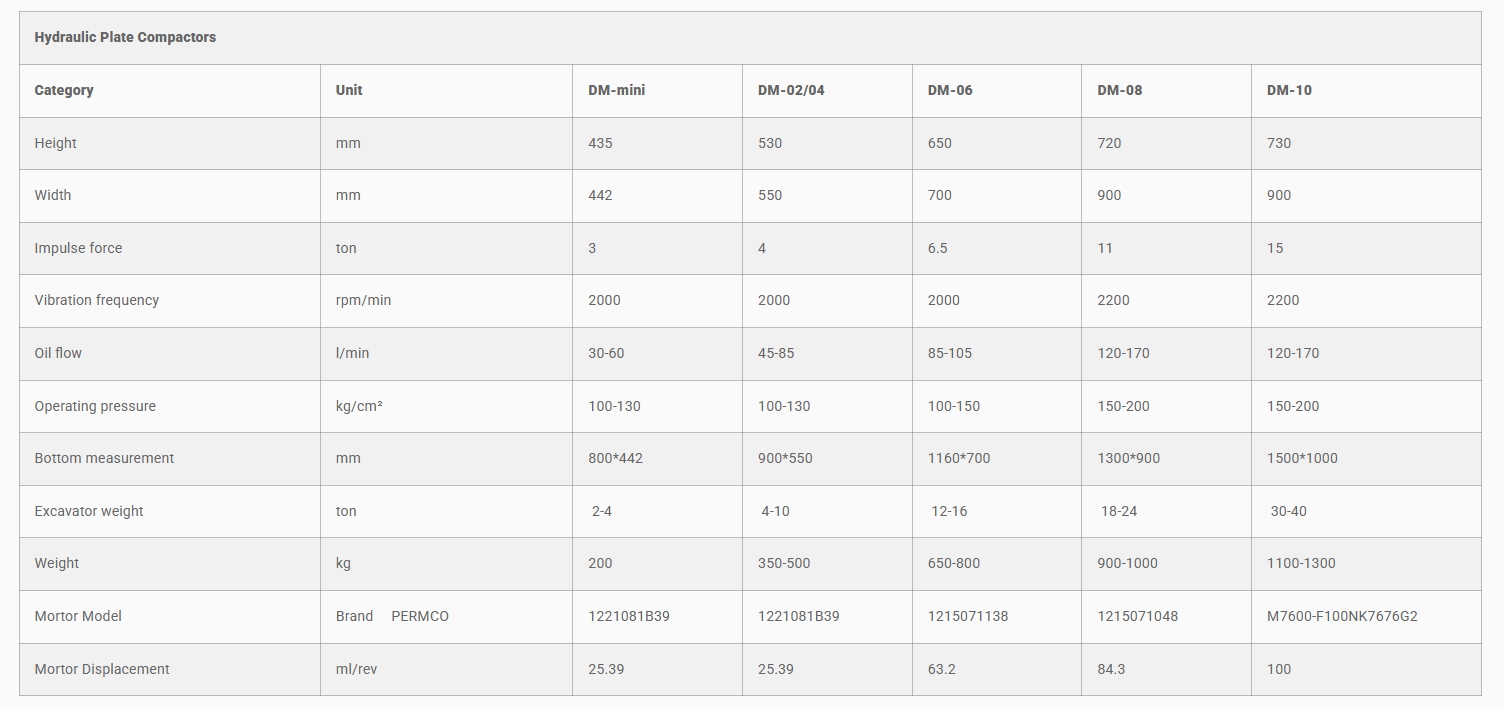

At METDEEM, we ensure every DM08 Compactor adheres to stringent quality standards with thorough pre-delivery testing. 12-hour technical support from the time of inquiry response is our after-sales service—a commitment we undertake for all our customers globally. Operators must comply with advised oil pressure (typically 160-180 Mpa) and flow rates (100-140 lpm) based on our specifications while using our DM-series attachments for optimal performance on excavators weighing 18-25 tons.

Working on Problematic Soil Types

Clay Soils

- Problem: Requires kneading action, swelling/shrinking tendency

- Solution: Use the METDEEM DM08 that provides static pressure or impact energy. Avoid high-speed vibration.

Sandy Soils

- Problem: Lack of cohesion, difficult to compact

- Solution: High-frequency vibration is essential. The vibratory action of the METDEEM DM08 Compactor is optimum for granular soils.

Mixed Soils

- Problem: Multivariate behavior requires a flexible approach

- Solution: Use versatile equipment that is adaptable to different conditions. The METDEEM DM08 Compactor suits a range of soil types and excavators (18-25tons), so it is ideally suited for dynamic sites.

Adapting METDEEM Compactors for Different Conditions

Our DM08 Compactor is compatible with various models of excavators like CAT, Komatsu, Volvo, SANY, XCMG. That compatibility makes it usable on various grounds without the need for much recalibration between uses. Wherever grading and compaction solutions are both required simultaneously, pairing the DM08 Compactor with a METDEEM Tilt Bucket enables smooth transitions between tasks with precision perfection over surface finishing and density measurements.

Why METDEEM for Compaction Solutions?

METDEEM manufactures construction attachments for performance and reliability under severe conditions. Our DM08 Compactor and Tilt Bucket are designed to address common compaction and grading issues, allowing teams to complete the job sooner and avoid costly mistakes.

Important Benefits

- Full Compatibility: Available for CAT, Komatsu, Volvo, SANY, XCMG, and more excavators.

- Long Lasting Reliability: All products undergo full pre-delivery testing and quality inspection.

- Expert Support: 12-hour technical response time for any inquiry.

- Warranty Protection: 6-month warranty with free replacement of defects.

FAQ

Q: What is the excavator size compatible with METDEEM’s DM08 Compactor?

A: The DM08 model can be utilized with 18-25ton excavators.

Q: How do I identify if I’m overcompacting?

A: Evidence is surface layer visible cracking or abnormally excessive bouncing of equipment in service—that is, no additional density gain is occurring despite multiple passes.

Q: What is METDEEM’s warranty?

A: METDEEM Excavator hydraulic Tilt Buckets are warranted for failure due to faulty design. Within 6 months, we offer free replacement.

Q: Where can I learn more about METDEEM attachments?

A: Visit our official website for full specifications on all the models, from trenching buckets, rock buckets, quick hitches, grapples, and others.