The Importance of Internal Sealing in Hydraulic Systems

In heavy construction equipment, hydraulic breakers play a key role in daily work. Their output depends a lot on the inside seals that hold steady hydraulic pressure. Oil leaks inside cut down on hitting power. They also harm the overall system’s work and lasting strength. This matters greatly in strong machines like our METDEEM DM230 Hydraulic Breaker Side Type. One key part that people often miss is the sealing seat ring.

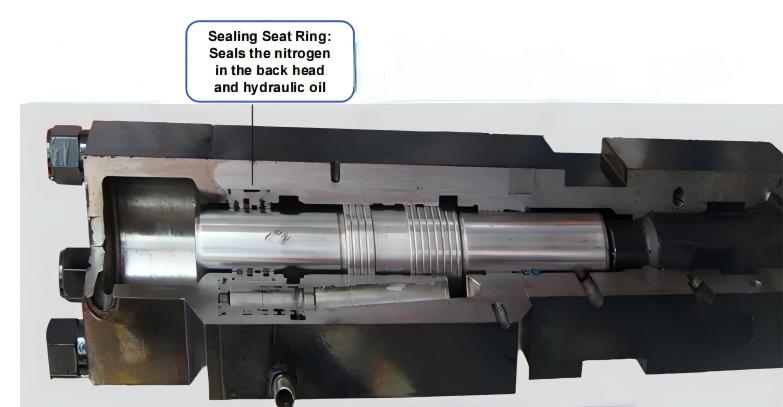

Sealing Seat Rings: Preventing Internal Leakage in Hydraulic Breakers

Maintenance on hydraulic breakers usually focuses on big parts such as the piston or chisel. But the sealing seat ring does a steady and essential job to keep performance even. Seals the nitrogen in the back head and hydraulic oil. In hydraulic breakers, this part keeps oil and gas inside where they belong. As a result, it boosts strike power and helps the system last longer.

How Internal Leakage Affects Performance

Pressure Drop and Impact Force Loss

Oil leaks inside lead to quick drops in pressure while the machine runs. This cuts the hitting force of the hydraulic hammer. The problem grows worse in tough setups. It fits little excavators and hard rocks. When leaks stay low, the excavator runs at lower speeds. This saves fuel. Defective sealing seat rings reduce hydraulic energy transmission to the chisel, lowering impact efficiency. So, the work suffers.

Increased Wear and Energy Inefficiency

Steady leaks do more than weaken hits. They speed up damage to the inside parts. Excessive friction and hydraulic fluid leakage over worn seals generates localized heat, accelerating component wear. This leads to early breakdowns. High-quality alloy steel goes through carbonitriding. The parts end up with hard surfaces and tough cores. They resist wear, avoid cracks, and serve for a longer time. Such waste means higher fuel use and more fixes. These costs add up, but good seals with METDEEM’s sealing seat rings can stop them.

The Role of Sealing Seat Rings in Pressure Control

Preventing High-Pressure Oil Leakage

The sealing seat ring acts as a wall between the nitrogen area and the oil area. The sealing seat ring functions as a gas seal, maintaining nitrogen pressure in the back head to support consistent hydraulic force. It keeps high-pressure oil in place. This powers the piston for top results. It works well in small units like the models METDEEM DM68 Top Type Hydraulic Breaker maintain optimal pressure control and impact force. The ring stops oil and gas from mixing. It also blocks leaks that hurt hitting energy.

Maintaining Consistent Working Pressure

A good sealing seat ring holds pressure levels steady. Each hit then gets full strength. Precision machining ensures concentricity of internal bores, maintaining hydraulic efficiency and impact consistency. Such steadiness helps in long runs, like breaking rocks or digging in mines. METDEEM’s design philosophy ensures our hammers maintain optimal performance over time with minimal pressure fluctuations.

Enhancing System Efficiency with METDEEM Components

Prolonging Seal System Lifespan

Sealing seat rings, engineered and heat-treated, minimize abrasion on adjacent seals. The piston is made of high-quality 40CrNiMo alloy steel after heat treatment. This means less need for fixes and better trust over many hours. Fleet managers with several machines find this key to smooth work.

Supporting High-Frequency Impact Operations

METDEEM sealing seat rings handle repeated high-pressure hits without bending. At identical pressure and flow rates, these sealing seat rings enhance operational speed and impact energy. This strength lets work go on without stops in hard spots like tunnels or breaking old concrete.

Key Features of METDEEM Sealing Seat Rings

Advanced Materials Used by METDEEM

Our sealing seat rings use top alloy materials that stand up to wear, rust, and heat strain. The cylinder block cavity is ground in a single setup on a CNC grinding machine. This results in higher precision and a smoother surface. These traits matter to keep the ring’s form and job under heavy pressure rounds.

Manufacturing Accuracy Standards

Every seat ring gets made with close limits for a perfect match in the hydraulic setup. Each cylinder body is machined using a CNC grinding machine and completed in one clamping operation. This care leads to top sealing work. It brings inside leaks close to zero. Precision like this shows in longer runs without issues, as seen in breaker logs from demolition sites.

Compatibility with METDEEM Hydraulic Hammers

Seamless Integration with Existing Systems

All METDEEM sealing components are built just for our hydraulic hammers. METDEEM DM35 Top Type Hydraulic Breaker. They fit right in with little need for changes or add-ons. Teams in the field swap them quickly, keeping projects on track.

Easy Replacement and Maintenance Procedures

To cut lost time, our sealing seat rings sit where they are easy to reach and swap during checks. Each attachment will be tested before delivery. Our QC will submit the inspection report before shipment. This setup speeds up fixes in the field or shop. It boosts work time.

Common Issues Without Proper Sealing of Seat Rings

Symptoms of Pressure Loss in Hydraulic Breakers

Users might spot clues like weaker hits, longer cycles, odd shakes, or uneven tool entry. These point to pressure troubles inside. They often come from broken or low-quality sealing parts.

Risks of Using Non-OEM Components

Parts not from the maker can cause bad fits or weak seals in the breaker build. Parts from any two breakers of the same model can be interchanged. Cheap options might save money at first. Yet, they miss the exact build needed for METDEEM setups. This brings lasting waste or full stops.

Conclusion

In tough work spots where output counts, our sealing seat rings are a must-have in our hydraulic setups. They hold pressure and guard other inside parts. Their part in keeping the hit force strong stands out clearly. Invest into maker-quality sealing parts like those from METDEEM brings gains in work rate, lower fix costs, and better machine life. With METDEEM, you will have more benefits and cost savings.

FAQ

Q: What causes internal leakage in a hydraulic breaker?

A: Internal leakage is often caused by worn seals or improperly fitted components like sealing seat rings that fail to contain high-pressure oil within the system.

Q: How does a sealing seat ring improve impact force?

A: By preventing internal oil leakage, the sealing seat ring helps maintain consistent working pressure, allowing each strike to deliver full impact energy.

Q: Can I use third-party sealing seat rings with my METDEEM hydraulic hammer?

A: It’s not recommended; non-OEM parts may not meet METDEEM’s precision standards, potentially leading to poor fitment and system inefficiencies.

Q: How often should a METDEEM sealing seat ring be replaced?

A: Replacement intervals depend on usage intensity, but regular inspection during maintenance cycles is advised to prevent performance degradation.