Importance of Component Durability

Hydraulic breakers face intense mechanical pressure, and their service life relies greatly on how well key parts like pistons and cylinders hold up. These carefully made components convert hydraulic energy into high-frequency percussive force. The choices in materials and methods help keep the hitting power steady and cut down on bending as time goes on. Still, even strong materials can suffer from dirt inside, which quietly speeds up breakdown.

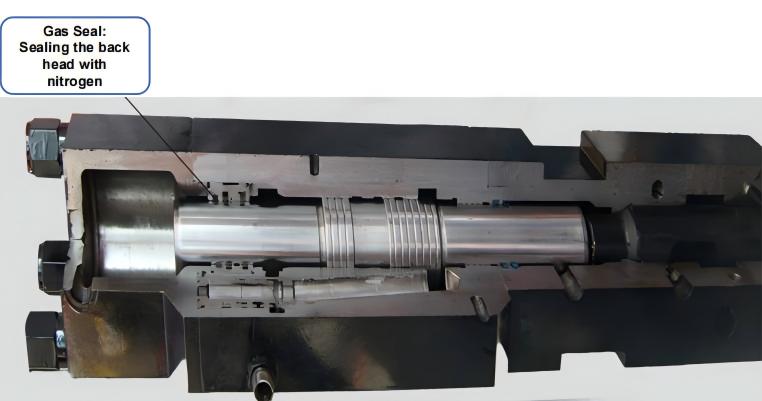

Introducing Gas Seal Technology

Hydraulic breakers cannot operate in areas with water or mud. Such unwanted stuff can slip into the inner parts via old seals or shifts in pressure. Once in, rough grains start scraping smooth areas on pistons, and water starts rusting on cylinder sides and valve parts. Over time, these intruders lead to rubbing damage, rust buildup, and seal breakdowns. In the end, this reduces impact energy and overall operating efficiency., throws off proper lining up, and raises the need for fixes.

To fight this ongoing problem, we at METDEEM created an advanced sealing solution designed for severe operating conditions: the gas seal. Our gas seal works as a shield, built to stop unwanted entry of dirt even in rough, heavy-duty tasks.

Sources of Internal Contamination

External Environmental Factors

Hydraulic breakers in mining or wrecking jobs face a high risk from outside dirt. Tiny dust from blasts, water from rain or muddy mixes, and flying sand all threaten the clean inside. The wide use shows why a solid sealing setup like the gas seal matters—it stands up to such harsh outside forces. For instance, in a typical quarry operation, a breaker might handle over 500 tons of rock daily, kicking up clouds of fine silica dust that cling to every surface. Without proper barriers, that dust finds its way inside during each cycle.

Operational Backflow and Pressure Surges

While running, hydraulic setups can hit sudden pressure jumps or brief backward flows. In those moments, dirty liquid might pull into the cylinder or valve areas. If seals wear out or sit wrong, the dirt skips past guards and reaches vital spots. Changes in pressure can pull in unwanted particles this way.

Lubrication System Compromise

Grease fittings offer another entry point for dirt. If grease picks up dust or water before use—or if seals around those points fail—impurities get forced right into inner paths. This not only speeds up rubbing but also hurts parts like bushings and piston rings. Take a farming scenario: the DM140 Hydraulic Breaker Box Type on a excavator in soil might need grease every few hours, but if the fitting cap loosens, mud mixes in and travels deep into the system.

Damage Caused by Contamination

Piston Surface Wear

Rough grains work like rough paper on piston faces. They scratch those faces, which lowers output. As the damage builds, the fit between piston and cylinder gets loose, boosting leaks inside. This pressure drop reduce the breaker’s hit strength and messes with straight-line work.

Cylinder Scoring and Corrosion

Water caught in the breaker rusts the metal faces. Cylinder walls, once dotted with rust or holes, fail to hold a good seal touch. Water causes rust inside and small pits on the cylinder walls. Small bits create scratches, harming the hydraulic seal’s strength.

Seal Degradation and Leakage Risks

Regular seals wear down slowly from rough grains and rust agents. Bit by bit, they lose bounce, letting liquid escape and cut hydraulic push and results. Unexpected stuff eats away at standard seals as days pass. Without protection, standard seals in hydraulic breakers may require replacement as frequently as every 150–300 operating hours under extreme dust exposure without advanced sealing protection.

METDEEM Gas Seal: Core Protection Technology

Design Principles of the METDEEM Gas Seal

Our gas seal fits high-pressure spots with a layered build that fights with hard bits. Made for strong sealing in high pressure with little rub loss. This setup gives firm closing action without dragging down work from extra friction.

How the Gas Seal Prevents Ingress

The gas seal works by maintaining a controlled gas-pressure buffer or air-compensation chamber between the external environment and internal components. It holds a steady gas buffer between the outside and inside areas. This buffer balances pressure changes and stops backward pulls that could drag in dirt. During a pressure drop, for example, the gas expands slightly to fill gaps, blocking any reverse flow—similar to a pressure-compensated barrier that prevents reverse flow ingress under transient pressure conditions.

Compatibility with High-Stress Applications

Put through strict tests in hard jobs like rock cutting and mine work, our gas seals show great staying power. They deliver solid results in mining breakers and cylinder breaker setups. They run well even with heat shifts, sudden loads, and ongoing shakes.

Extending Equipment Lifespan with Gas Seals

Reduced Wear on Precision Components

By stopping dirt entry right at the start, gas seals help keep the close fits between pistons and cylinders. A clean inside space keeps the piston-cylinder fit tight for a longer time. This cuts down on surface tiredness from repeated hits and stretches work life a lot.

Enhanced Reliability in Harsh Conditions

For breakers in rough or damp work areas, the gas seal gives key shielding that holds system wholeness over the years. It keeps sealing strength in wet, dusty, or rough settings.

Lower Maintenance Costs Over Time

Less need for seal swaps means shorter stops. Guarding inner parts like valves and pistons pushes back big fixes. Safeguarding inside lengthens the time between full checks a great deal.

Long-Term Operational Value of Gas Seals

Improved Equipment Uptime Rates

Fewer failures turn straight into better work output per running hour. Teams using METDEEM hydraulic breakers, backed by our gas seal tech, note faster job finishes and fewer fix stops.

Optimized Total Cost of Ownership

While costing more at first than basic seals, our gas seals bring savings later by cutting part damage, worker time, and liquid waste. The starting spend on METDEEM gas seals pays back via full-life gains.

Supporting Sustainable Operations

By stretching part life spans, gas seals cut trash from often-swapped pieces. Longer parts use less waste from regular throwaways. This aligns with green standards in construction, where reduced metal scrap helps meet recycling goals set by industry groups.

Conclusion

By stopping outside intruders such as dust, water, and rough grains, the gas seal shields valuable parts like pistons and cylinders from early rubbing, rust, or scratch harm. This not only lengthens the run time of METDEEM hydraulic breakers and other types but also cuts fix costs a lot while boosting steady work across many uses.

For workers looking for tough fixes that cut stop times while raising gear worth over the years, adding METDEEM’s gas seal stands as a smart spend in lasting results.

FAQ

Q: How does internal contamination occur in hydraulic breakers?

A: Internal contamination typically results from dust, moisture, or debris entering through worn seals or pressure reversals during operation.

Q: What makes METDEEM’s gas seal different from standard seals?

A: METDEEM’s gas seal uses a multi-barrier system that resists both solid particles and moisture while maintaining seal integrity under high-stress conditions.

Q: How does using a gas seal affect maintenance frequency?

A: By preventing contamination-related wear, the gas seal reduces the need for frequent part replacements or overhauls.

Q: Is it cost-effective to upgrade existing breakers with METDEEM’s gas seals?

A: Yes, the long-term savings from reduced wear, lower maintenance costs, and improved uptime outweigh initial upgrade expenses significantly.