What Is an Auger Drill

An auger drill stands as a reliable tool made for boring holes in the soil with care and quickness. It relies on a helical blade, commonly called an auger drill flighting to scoop out dirt and shape round holes. Folks in fields like building sites, farming areas, yard care, and utility installation often turn to auger drills. Their adaptability and knack for dealing with all sorts of ground make them a go-to pick.

How an Auger Drill Works

An auger drill runs on a simple idea. A spinning coiled shaft slices into the dirt. It then pulls the material up and out of the hole. Power comes from hydraulic motors or PTO drives, usually mounted on excavators or skid steer loaders. The auger drill bit turns steadily. As it does, soil moves up the twisted blades. The dirt then spills out near the hole. This process maintains a clean, efficient excavation. METDEEM auger drill application in Landscaping, Tree planting, Well boring, Foundation piles, Screw pile installations, Ground source heat pumps, Pole and Mast Installations, Solar energy piling, Bridge pier drilling, etc.

Key Features of METDEEM Auger Drills

Durable Construction

METDEEM auger drills come together with a solid Planetary Reductions Gearbox. It includes a large-diameter output bearing. Our team developed a custom Gearbox layout. They also used particular heat-treating techniques. These steps create an auger drill with strong torque. Such parts stand up to hard use over long stretches. For example, on a road project where crews drill through packed gravel for hours each day, this build helps avoid early breakdowns. Workers can count on it to keep going without constant fixes, saving time and hassle in the field.

Interchangeable Drill Bits

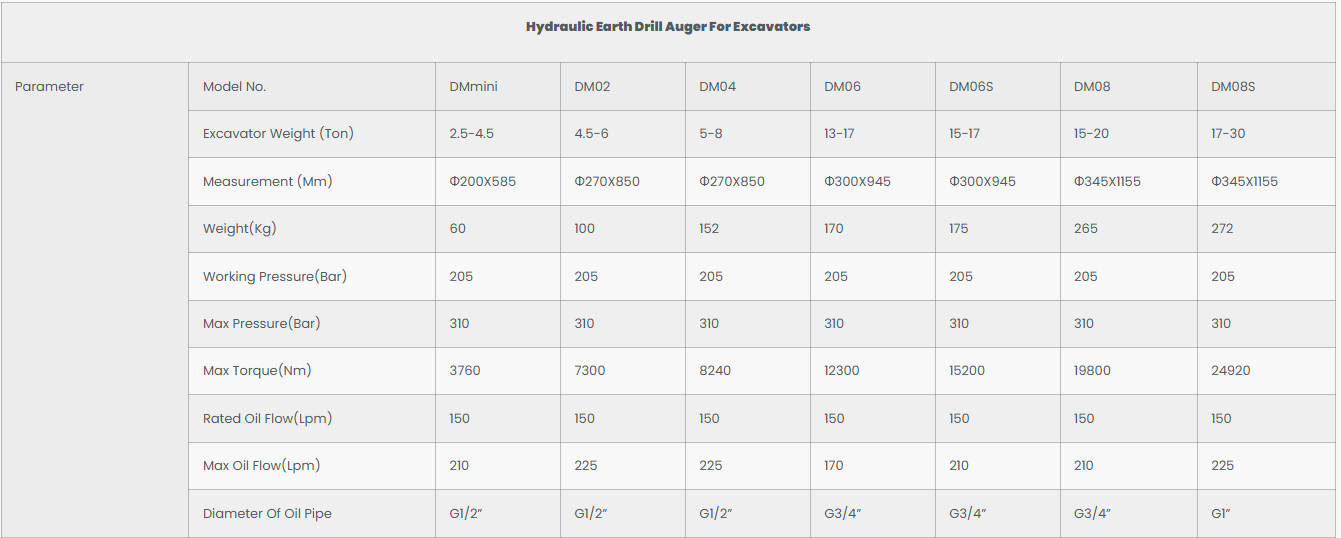

A big plus for METDEEM augers drill lies in their variety of choices. Models such as DM mini, DM02, DM04, DM06, DM06S, DM08, and DM08S match up with different bit sizes. They also handle various drilling depths. These augers drill fit the needs for all kinds of widths and levels based on the work ahead. In a typical setup, a landscaper might swap bits on a DM04 to go from 4-inch posts to 12-inch tree holes in one afternoon. This switch keeps the job flowing without stopping for a new gear.

Compatibility with Power Tools

METDEEM puts out a broad lineup of auger drills. They pair nicely with excavators weighing 2.5 to 30 tons. This setup means they work smoothly with many types of equipment in diverse areas. Take a small crew on a residential lot: they hook up a DM mini to a 3-ton machine for fence work. Later, the same team shifts to a 20-ton unit for piling on a bigger site. No need for special adapters each time.

Safety and Efficiency

The auger drill bit is secured with a keyed or non-slip output shaft to prevent disengagement during operation. It lowers the chances of mishaps. At the same time, it improves steady workflow. On busy sites with tight spaces, this feature lets operators focus without worry. A slip could mean downtime or injury, but here it stays locked in place.

Common Applications

Landscaping and Gardening

Auger drills ease up work on things like setting fence posts, adding small bushes, or making spots for water pipes. They dig neat holes in a flash. This cuts down on time spent and the sweat of hand-digging. Imagine a park crew outfitting a playground: instead of hours with shovels for 50 posts, an auger drill finishes the task in under two hours. The ground stays level, and the team moves on to planting without sore backs.

Tree Planting

Tree planting typically requires deep and wide holes to accommodate root balls, and auger drills provide the necessary torque and diameter efficiently. METDEEM auger drills deliver the pull and bit types required to get trees in place fast. They suit home yards as well as large business lots. In a community orchard project, for instance, the DM06 model’s torque chews through root-filled soil to create 18-inch deep spots. Roots settle right, and trees grow strong from day one, based on what growers report after seasons of use.

Well Drilling

Setting up short wells calls for a practical and cost-effective approach. Auger drills fill that role well. METDEEM units bring solid torque to break through mixed ground layers, from soft silt to firmer topsoil. A rural setup might involve a DM02 on a light excavator to hit 6 feet for a water source. It wraps up quicker than manual methods, and at lower expense than full rigs, helping small farms get water flowing without big budgets.

Foundation and Piling Work

METDEEM auger drills see plenty of action in foundation piles, screw pile jobs, and bridge pier digs. In these spots, careful work and solid power build a steady base. For a warehouse built on uneven land, the DM08 bores precise 24-inch holes through clay and stone. This ensures the structure holds firm, drawing from years of contractor feedback on similar builds where shaky starts led to costly redo’s.

Advantages of Using METDEEM Auger Drills

Time-Saving Operation

Parts like top-grade imported hydraulic motors and made-to-fit gearbox setups let METDEEM auger drills clear dirt at a good pace. They trimmed down the total project days quite a bit. Picture a fencing company lining up 200 posts along a property edge. With a DM04, they knock it out in one shift instead of three. The smooth pull and steady power mean fewer pauses, keeping schedules on track even in wet weather.

Precision and Consistency in Drilling

Each METDEEM model is engineered for precise drilling. The customized auger drill flighting efficiently conveys soil out of the hole. As a result, holes end up tidy and matching in shape. On a utility line install, this means every 10-foot dig line up perfectly for poles. Our customers appreciate how it avoids the guesswork of uneven depths, which could tilt setups and call for adjustments later.

Versatility Across Multiple Tasks

METDEEM lines cover from 2.5-ton small excavators to 30-ton big machines. Each model suits the gear size at hand. This range lets workers stick with one auger drill style over different spots. A rental outfit, say, loads a DM06S onto various client machines—from city lots to rural fields—and it performs without tweaks. Over a season, this cuts down on tool swaps and boosts overall job flow.

Choosing the Right METDEEM Auger Drill

Factors to Consider (Soil Type, Hole Size)

Ground varies a lot, from sticky clay to shifting sand or bumpy rocks. Each type needs its own torque amount and bit scale. Getting a read on the site’s setup points to the best model. Crews often scout first—maybe test a small dig—to match power right. For example:

- DM mini: Suitable for 2.5-4.5 ton excavators with a max torque of 3760 N/m.

- DM08S: Designed for 17-30 ton excavators with a max torque of 24920 N/m.

METDEEM Auger Drill operate typical working pressure ranges from 205–310 bar, depending on the model.

Matching Drill Types to Specific Jobs

Light yard chores call for the DM mini. It gets the basics done without fuss. Heavy lifts, though—like solar panel bases or bridge supports—point to the DM08 or DM08S. Their stronger torque and flow handling suit the demands. During a wind farm rollout in hilly ground, teams chose the DM08S for 15-foot bores. It handled the mix of dirt without bogging down, finishing sections ahead of plan and under budget.

Maintenance Tips

Cleaning After Use

Once the job wraps, scrape off every bit of soil and junk from the auger drill flighting. This blocks rust or clogs that might slow things later. A field tech’s routine often includes a hose blast and a wire brush right at the site. It takes minutes but keeps the tool sharp for the next call, much like clearing mud from boots to avoid slips.

Lubrication and Storage Practices

Hit all the working joints with grease on a steady basis. This fights off grinding and early wear. Tuck the auger drill away in a dry area. Covers help shield it from rain or dust if out in the open. Many operators share stories of units running five years strong with weekly checks—simple steps that add up to less shop time and more field hours. Each attachment will be tested before delivery. Our QC will submit the inspection report before shipment. METDEEM Excavator Auger Drills are guaranteed against failure due to defective design, materials, or workmanship for a period of one year or 2,000 hours. Free replacement service within the first 6 months.

Conclusion

As a trusted manufacturer in construction machinery attachments, we at METDEEM take pride in delivering not just products but performance solutions that meet real-world demands. Whether you’re planting trees or laying deep foundations, our auger drills are engineered for reliability, efficiency, and safety.

FAQ

Q: What size excavators are compatible with METDEEM auger drills?

A: METDEEM offers a huge range of earth drills to suit 2.5-30T excavators, ensuring compatibility from compact machines to large-scale excavators.

Q: Can I use METDEEM auger drills for rocky terrain?

A: Yes. With high torque models like DM08S generating up to 24920 Nm, they are capable of handling tough ground conditions, including rocky layers.

Q: Are there extension options for deeper drilling?

A: We can offer a comprehensive range of auger drill drives, auger drills, extension bars, and cradle hitch, etc. Custom solutions can also be provided based on your project needs.

Q: Where can I get support or spare parts?

A: METDEEM provides reliable after-sales service, spare parts support, and professional consultation via Metdeem108@126.com or call +86-15318660928.