Overview of Breaker Technologies

In the construction and demolition industry, it is important to have the right breaking equipment to ensure the success of a project. As a professional manufacturer of construction machines and attachments, METDEEM is a reliable manufacturer of construction machines and parts. Our products are widely used in construction sites, mining, farming, agriculture, quarrying, and other industries.

What Are Hydraulic Breakers

Hydraulic breakers utilize the hydraulic circuit of excavators or other heavy machines to generate high impact forces. Hydraulic breakers are directly connected to the hydraulic circuit of the host machine, and they do not need separate air compressors. Our lineup of hydraulic breakers includes models for various sizes of excavators, from compact machines to heavy applications.

What Are Pneumatic Breakers

Pneumatic breakers are powered by compressed air systems, which generate high-frequency impacts through air pressure. Pneumatic tools operate by using compressed air to drive a piston that strikes the breaking tool repeatedly. The power source is an air compressor, which delivers pressurized air through hoses to the breaker unit. Pneumatic breakers find extensive use in small-scale demolition and are best suited for demolishing concrete, asphalt, and masonry structures.

Working Principles and Energy Consumption

How Hydraulic Breakers Operate

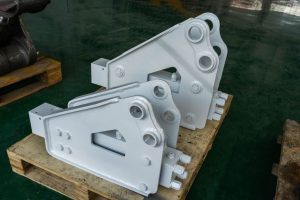

This 2.0 to 2.5 excavator Mini Hydraulic Rock Breaker features a rugged construction with damage-preventing materials and stable performance, which ensures low fault rates. Hydraulic breakers are powered by pressurized hydraulic fluid from the host machine. The hydraulic flow drives a piston in the housing of the breaker, which creates powerful impacts by using hydraulic pressure and the accumulation of nitrogen gas. The DM35 model, for example, is adapted to 2-3 ton excavators, uses a 58mm chisel, and has a weight of 160kg. It requires a hydraulic flow of 25-45 L/min and operates at a pressure of 90-140 kg/cm² with 500-1200 bpm.

How Pneumatic Breakers Work

Pneumatic breakers work on a relatively simple mechanism. Compressed air is admitted to the cylinder of the breaker and drives a piston back and forth at high frequency. The piston strikes an impact mechanism, which transfers energy to the breaking tool or chisel. Air pressure ranges from 90 to 150 PSI, and impact frequency varies with the model and application requirements. The continuous flow of compressed air provides stable operation, with performance being affected by air pressure and temperature variations.

Energy Consumption Comparison

Hydraulic breakers are more energy efficient compared to pneumatic ones. While air compressors in pneumatic systems are typically 20-25% efficient due to compression losses and heat generation, hydraulic systems are far more efficient. This results in less fuel being used per unit of work, making hydraulic breakers cost-effective for longer operations.

Key Comparison: Hydraulic vs. Pneumatic

Performance in Different Work Environments

Suitability for Light and Medium-Duty Operations

Both hydraulic and pneumatic breakers are ideal for light and medium-duty operations. Pneumatic breakers excel at applications requiring precise control and frequent repositioning, while hydraulic units provide constant power output regardless of the ambient conditions.

Performance in Heavy-Duty Demolition Work

Hydraulic breakers excel on heavy-duty demolition work due to their high power-to-weight ratio and consistent performance. The METDEEM 1550 hydraulic breaker, compatible with 26-35 ton excavators, features a 135mm chisel diameter, 400-800 bpm impact rate, and 125-150L min working flow.These units can maintain high impact energy even in challenging conditions and are ideally suited for demolishing reinforced concrete, difficult rock formations, and structural demolition.

Noise and Vibration Levels in Operation

Noise reduction and reduced vibration render the operator-friendly and advantageous to the public and the environment around it. Hydraulic breakers tend to be quieter than pneumatic ones, even considering the noise generated by air compressors. The low vibration characteristics of hydraulic systems also mean greater operator comfort and reduced fatigue with extended use over time.

Maintenance and Durability

Maintenance Considerations for Hydraulic Units

delivers optimum performance with less maintenance. Hydraulic breakers benefit from the host machine’s hydraulic system maintenance, which reduces the individual maintenance requirement. Regular hydraulic fluid change, replacement of filters, and seal inspection ensure optimum performance. METDEEM Excavator Hydraulic hammers are guaranteed against failure due to faulty design, material, or workmanship for a period of one year or 2,000 hours. For the first 6 months, we offer a free replacement service.

Typical Maintenance Requirements of Pneumatic Tools

Pneumatic breakers require regular maintenance for both the air compressor system and the breaker unit. Daily maintenance includes checks on air filters, draining of water from air tanks, and inspection of hoses for any damage. The air compressor requires regular oil changes, filter replacement, and belt tightening. Moisture control is extremely critical since water entry will cause internal corrosion and seal failure.

Longevity and Resistance to Wear

New in design and more power in a thought-through physical design. Hydraulic breakers tend to have greater longevity since they are designed to be robust and have steady operating conditions. The absence of moisture-related corrosion issues, along with the precision of hydraulic control systems, is a factor in longer service life and reduced demand for replacement parts.

Cost Considerations and Return on Investment

Initial Purchase Costs

The initial acquisition cost differs greatly for pneumatic and hydraulic systems. Although pneumatic breakers might have lower initial costs, the necessary air compressor investment usually matches or surpasses hydraulic breaker costs. Hydraulic breakers are a single-point purchase that is compatible with an existing fleet of excavators.

Operating Costs Over Time

Operating cost analysis strongly favors hydraulic systems. The fuel consumption of air compressors, as well as the higher maintenance requirements, tends to make per-hour operating costs for pneumatic systems greater. Hydraulic breakers reap the benefit of the host machine’s existing fuel consumption and maintenance intervals.

Long-Term Value Analysis

DM35 hydraulic breaker offers speed, high productivity, low maintenance expense, and long service life. Long-term value comparisons always favor hydraulic breakers since they are more durable, less maintainable, and have greater performance consistency. The operation with existing excavator fleets assures maximum equipment utilization and minimum standalone equipment needs.

Safety and Operational Control

Safety Features of METDEEM Hydraulic Breakers

DM35 hydraulic breaker is CE marked for compliance with EU safety standards and for ease of entry into the market. Our hydraulic breakers incorporate advanced safety mechanisms like automatic shut-off, pressure relief, and rugged housing designs. Synchronization with the safety systems of the excavator provides additional protection through integrated control systems.

Safety Features of Pneumatic Breakers

Although our primary focus is hydraulic technology, most current pneumatic breakers also include safety features like pressure relief valves, ergonomic handles, and vibration-dampening systems. Controlled air pressure eliminates over-pressurization and potential equipment damage.

Operator Training and Ease of Operation

Hydraulic breakers also require less specialized operator training since the majority of excavator operators already have a handle on hydraulic attachment operation. The learning curve associated with pneumatic systems, such as operating an air compressor and managing pressure, makes operator training requirements more complex.

Applications Throughout Construction Projects

Roadwork and Pavement Breaking

Both pneumatic and hydraulic breakers are effectively used in roadwork applications, with hydraulic machines being favored in continuous operation scenarios. Roadway maintenance projects value the mobility and power consistency of hydraulic systems, while smaller municipal projects can frequently utilize pneumatic alternatives for their comparative simplicity.

Quarrying and Mining Tasks

Our products are widely used in construction sites, mining, farming, agriculture, quarrying, and other fields. Quarry operations need the constant high-impact energy that hydraulic breakers provide. The harsh environmental conditions and lengthy operating hours in mining applications are well matched to the strength of hydraulic systems and their durability.

Urban Demolition Projects

Hydraulic breakers assist urban demolition work with their reduced noise and improved control characteristics. The lack of air compressor noise and the precision control achievable with hydraulic systems make these tools ideally suited for noise-sensitive city environments.

Choosing the Right METDEEM Breaker Type

Project duration, working space, compatibility with available equipment, and budgetary constraints are all factors in breaker selection decisions. You may rest assured that our entire product line can be supplied in a wide range of designs, and the product can be customized according to your particular requirements. Our technical personnel provide consultation services to assist in ensuring correct equipment selection for the application being considered. Successful project outcomes depend on matching breaker capacities to the specific requirements. Consider impact energy requirements, duty cycle requirements, and integration compatibility with existing equipment fleets. We promise to get back to you upon receipt of your inquiry within 12 hours.

FAQ

Q: What maintenance routine should I follow for hydraulic breakers?

A: All attachments are inspected before shipping. QC will issue an inspection report before shipping. Follow manufacturer recommendations, typically including daily visual checks, weekly lubrication checks, and periodic hydraulic fluid analysis.

Q: Can I use the same excavator with various breaker types?

A: Yes, most excavators today are designed to accept both pneumatic and hydraulic attachments with the use of proper connection systems and auxiliary hydraulic circuits.

Q: How do I choose the correct breaker size for my excavator?

A: Breaker choice should correspond to your excavator’s hydraulic flow and pressure capabilities.