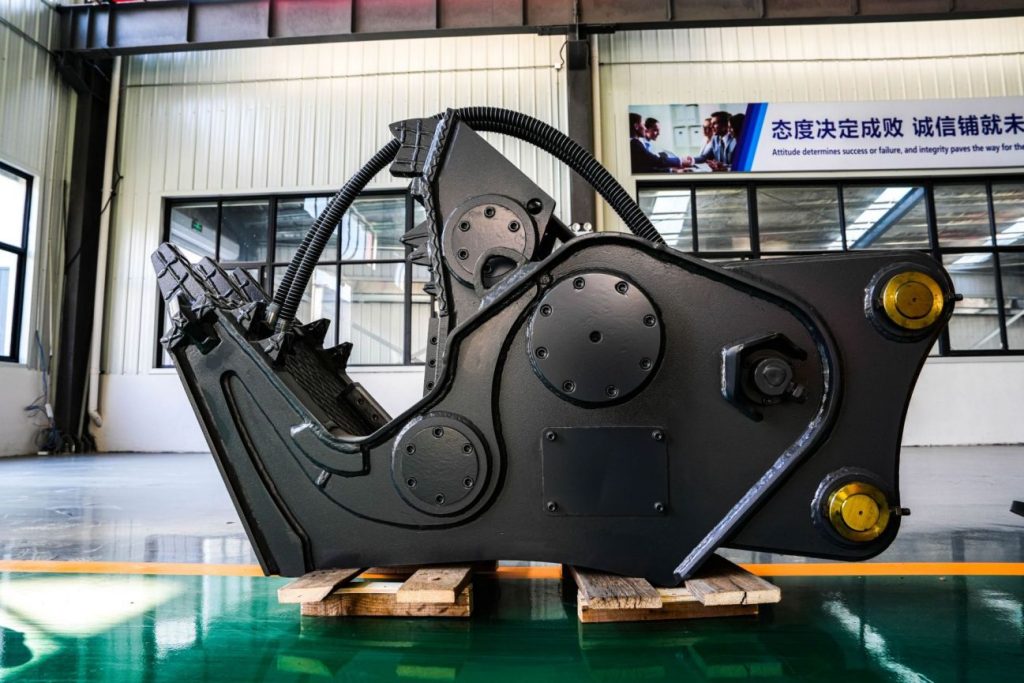

Demolition is all about speed, precision, and safety. Removing massive concrete structures, de-rebarbing, and grinding rubble can take time and be laborious. Hydraulic pulverizers achieve them by combining raw power, efficiency, and operator protection, making them essential equipment on modern demolition sites. In the following guide, we explain how hydraulic pulverizers operate, the most important parts, on-site advantages, and why METDEEM attachments are used by worldwide specialists.

Understanding Hydraulic Pulverizers

A hydraulic pulverizer is an especially engineered demolition machine that is capable of crushing tough material and concrete effectively. It is mounted on an excavator, and it leverages the machine’s hydraulic system in order to create extremely high forces to dismantle reinforced structures into fragments. It is extensively used in construction, road construction, mining, and metallurgy sectors due to its capacity to:

- Crush concrete effectively.

- Split rebar embedded in concrete.

- Reduce the quantity of waste to recycle.

Hydraulic pulverizers enable contractors to save time, reduce labor, and enjoy cleaner, safer working conditions.

Main Components and Their Functions

The main components of a hydraulic pulverizer are:

- Jaw Set: It consists of a stationary jaw and a moving jaw, which break the concrete.

- Hydraulic Cylinder: Provided crushing pressure.

- Reinforced Frame: Designed to withstand high stress.

- Replaceable Teeth/Blades: Made to cut the rebar and concrete.

Each part plays a vital role in the operation of the pulverizer in adverse environments. Teeth are used to crush and hold material, and equal pressure is developed by the hydraulic cylinder to allow effective demolition.

How Hydraulic Pulverizers Work

The Basic Working Principle

Hydraulic pulverizers operate based on utilizing the hydraulic energy of an excavator. The instant the pulverizer is engaged, hydraulic fluid fills the pulverizer cylinder and jams the mobile jaw into the stationary jaw with tremendous pressure. The pressure permits crushing concrete and compacted rubble and even slices through embedded steel reinforcement. Breaking force is consistent as long as there is hydraulic pressure, which enables workers to work with huge amounts of material within a span of time without the use of human muscle force.

Integration with Excavators

Hydraulic pulverizers have one of the strongest advantages of being integrated easily with excavators. Hydraulic pulverizers have quick hitches for easy attachment switching. METDEEM, for instance, comes with Tilting Quick Hitch Coupler DM02A/B, which is characterized by 180°tilting and 4400 NM drive torque, utilized in 4–6 ton excavators—ideal for dirty places like under roots or pipes. This incorporation also ensures maximum on-site equipment flexibility by enabling instant switching between digging, breaking, and crushing operations without a machine change.

Benefits of a Demolition Site

Quick Concrete Processing

Demolition work is quick. Hydraulic pulverizers achieve significantly faster concrete processing compared to other conventional methods like jackhammers or hand tools. With their powerful heavy crushing capacity, they easily disintegrate large blocks of concrete into smaller towable pieces or reusable pieces. Our hydraulic breakers are made from high-strength alloy steel with a progressive hydraulic system design that provides high-impact energy, penetration speed, and high efficiency. The same philosophy is extended to our pulverizers—speed without losing strength.

Less Downtime and Manual Labor

With all the work divided, hydraulic pulverizers reduce manpower reliance. Labor no longer has to waste hours breaking up concrete material. With less labor comes less injury and less cost per man. In addition, attachments like METDEEM’s Tilt Bucket DM02 allow laborers to work at the optimal angle when doing work without having to move the machine constantly, also saving downtime.

Improved Worker Safety

Demolition exposes people to the risk of falling debris or collapsing structures. Hydraulic pulverizers keep operators safe because they can operate from within an excavator cab. Controlled crush machinery produces repeatable results with fewer airborne particulate hazards than traditional impact tools. Additionally, noise reductions and low vibration make METDEEM machines operator-friendly and beneficial to people and the environment in their local settings.

Role in Material Processing

Effective Rebar Separation

Modern hydraulic pulverizers can effectively eliminate embedded steel from ruptured concrete. METDEEM possesses clamping teeth that hold both materials together as it shears across the rebar without using secondary tools, allowing separation of the material to be practical and saving cleanup time.

On-Site Recycling

Used concrete is recycled as base course or backfill or sold as rebar-separated scrap metal. METDEEM Rock Bucket DM02 also has hardened pointy teeth that can cut hard surfaces, so sorting can be done effectively in excavating or demolition after clearance.

How METDEEM Leads

Why METDEEM Excels

METDEEM provides heavy-duty excavator attachments used in construction, mining, road breaking, and agriculture. Products are extensively tested for quality, ISO 9001 certified, and CE marked. Hardox500 and Q355 steel provide attachments with high strength to manage heavy loads. METDEEM attachments fit large excavator brands such as CAT®, Komatsu®, Volvo®, SANY®, and XCMG®.

Key Factors to Consider

When selecting a pulverizer:

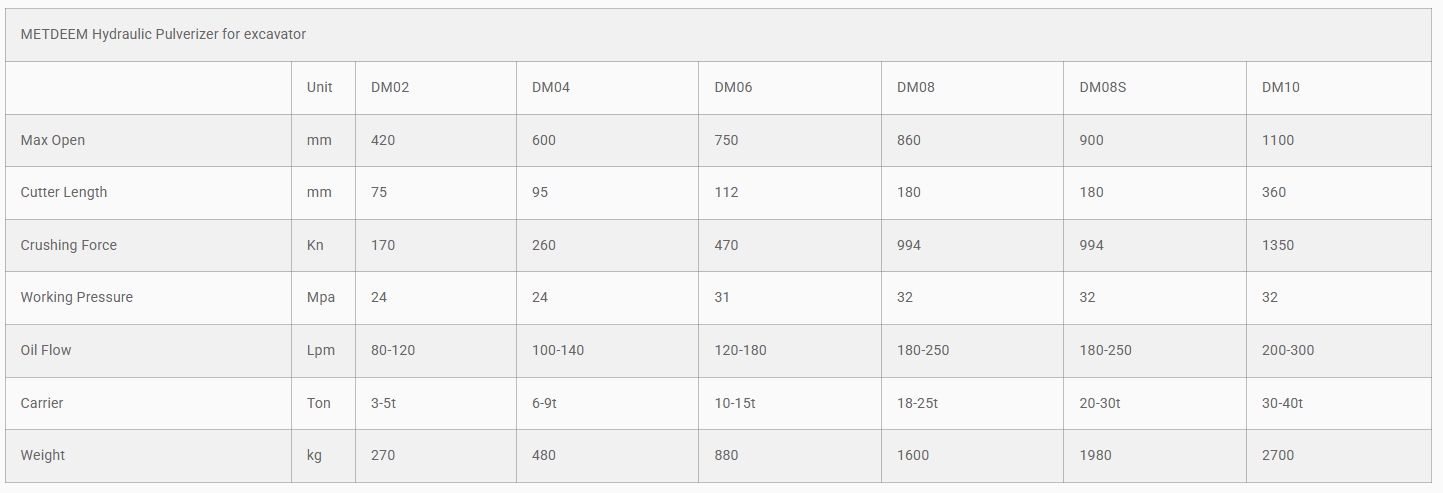

- Excavator Compatibility: Ensure the weight class is the same for your machine.

- Material Strength: High-strength material like Q355B/NM400 could be used.

- Jaw Design: Tooth plates with replaceable teeth are apt for reinforced constructions.

- Hydraulic Requirements: Parallel flow rate (Lpm) and pressure (Bar) demands.

- Application Type: Fixed or rotatable type based on the type of job.

METDEEM is willing to customize OEM/ODM—just send in your design, and the R&D department will create custom solutions for you.

Maintenance and Durability Tips

Daily Inspection Checklist for Use

For the best performance at your demolition site

1. Look for leaks or hose wear.

2. Daily inspection of blades/tooth condition.

3. Tighten all bolts/pins.

4. Lubricate pivot points daily.

5. Priority to oil levels within acceptable limits.

6. Nothing should limit jaw movement.

Scheduled inspections avoid surprise failures that will lead to a poor rate or escalate the repair expense.

How to Lengthen the Life of Your METDEEM Pulverizer

Sustainability starts in design—and we build all attachments from long-lasting material like Q460+Q355 steel pairs known for withstanding wear under heavy loads. All pins are heat-treated, rigid, and durable.

To enhance lifespan:

- Store indoors when not operating.

- Never overload.

- Replace worn components ahead of time.

- Operate within proper operating pressures (refer to model specification).

Our warranty demonstrates this commitment—METDEEM Excavator attachments are guaranteed to be free from failure because of defective design, material, or workmanship for one year or 2,000 hours.

FAQ

Q: What materials can a hydraulic pulverizer process?

A: Hydraulic pulverizers are utilized to crush concrete with rebar, stone, asphalt, and other hardened building materials and to efficiently clean out embedded steel rebar.

Q: How do hydraulic pulverizers improve safety in demolition?

A: They allow operators to do demolition from the comfort of the excavator cab, hence minimizing exposure to falling objects, minimizing flying chips, and minimizing workers’ physical fatigue.

Q: In what way does an in-place recycling project profit from having a hydraulic pulverizer?

A: It shatters concrete into reworkable pieces and efficiently shears steel rebar, so material can be recycled to be repurposed as backfill or recouped for scrap metal without extra time-wasting separating.

Q: What type of maintenance will maintain a hydraulic pulverizer in good operating condition?

A: Regular checks on hoses, teeth, bolts, and hydraulic oil levels, as well as continuous lubrication and replacement of worn components, guarantee maximum efficiency and durability.