Understanding Mechanical Grapples

What Is a Mechanical Grapple

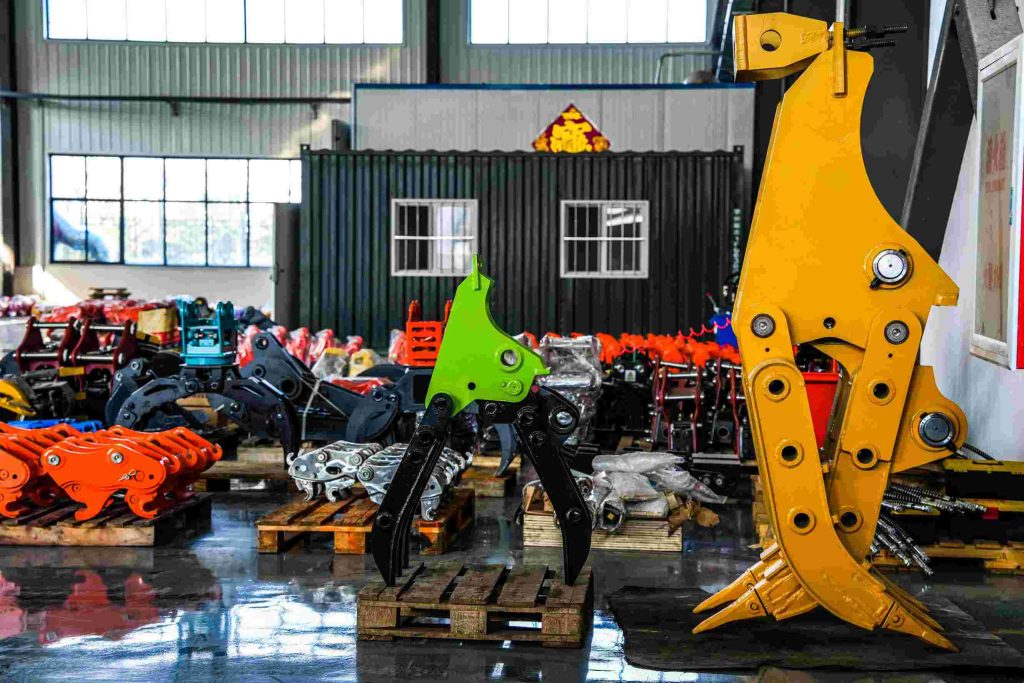

Mechanical grapples are heavy-duty excavator attachments used to grab, lift, and move material such as wood, rocks, metal scrap, and trash. Hydraulic grapples rely on fluid power, but mechanical grapples use the force of the movement of the arm of the excavator to open and close their jaws, thus being less complicated in design and simpler in maintenance. They are required in applications where material handling efficiency is directly translated into productivity.

How Mechanical Grapples Operate

A mechanical grapple operates through the use of a linkage system that is mounted on the bucket cylinder or quick coupler of the excavator. The bucket cylinder’s movement by the operator drives the movement of the tines or jaws of the grapple to grab or release the material. This mechanical action replaces other hydraulic circuits, reducing and possibly precluding maintenance issues.

Advantages of Operating with a Mechanical Grapple

Mechanical grapples also have several advantages. They are more durable with fewer accessories and no hydraulic hoses to break or leak. Their minimalism makes them cheap and easy to fit. Additionally, they have excellent gripping force for handling awkwardly shaped loads like logs or demolition debris. METDEEM’s Mechanical Grapples DM08 is a prime example of such efficiency-focused design.

Common Mechanical Grapple Types

| Grapple Type | Primary Applications | Ideal For Materials | Key Features |

|---|---|---|---|

| Wood Grapples | Forestry, logging, land clearing | Logs, timber, biomass | Wide jaw opening, curved tines, strong clamping force |

| Rock Grapples | Quarry, mining, construction | Boulders, stones, heavy debris | Reinforced tines, abrasion-resistant construction |

| Scrap & Waste Grapples | Recycling, demolition, scrap yards | Metal scrap, construction waste, debris | Sharp tines, large opening, durable structure |

| Multi-Purpose Grapples | General construction, farming | Mixed materials, light debris | Versatile design, balanced performance |

Key Applications by Industry

- Forestry & Logging: Optimize efficiency and safety during log loading and handling operations.

- Construction & Demolition: Quickly load and remove broken concrete, rebar, and construction debris.

- Recycling & Waste Management: Simplify sorting and transferring scrap metal and industrial waste.

- Agriculture & Land Clearing: Clear stumps, rocks, and brush piles from the land easily.

- Mining & Quarrying: Grapple with heavy rocks and abrasive material using specialized rock grapples.

How to Choose the Right METDEEM Grapple: A 4-Step Guide

Step 1: Get a Grapple to Fit Your Excavator Size

Compatibility is step one and most critical. Ensure that the grapple matches your excavator’s weight class. Running an attachment that’s heavier or lighter than optimal will adversely affect performance and may be unsafe. Quick Reference Guide:

- Mini Excavators: Light-duty compact grapples.

- Medium Excavators: All-around grapples for general use.

- Large Excavators: Heavy-duty grapples for heavy work.

Step 2: Select Your Primary Material Type

The type of material you use most often determines the optimum grapple type. Remember these specialized ones:

- For Logs and Biomass: Choose wood that grapples with open spaces.

- For Rocks and Boulders: Employ reinforced rock grapples with closed tines.

- For Scrap Metal and Demolition: Employ steel grabs with sharpened, penetrating tines.

- For Mixed Materials: Employ multi-purpose grapples for flexibility.

Step 3: Check Technical Specifications

Pay attention to these critical specifications:

- Jaw Opening Width: Determine the maximum size of load you can handle.

- Weight Capacity: Ensure it is your standard load weight requirement.

- Quality of Construction: High-strength steel (Q355Mn or equivalent) construction.

- Maintenance Requirements: Consider types of bearings employed and seal integrity.

Step 4: Consider Your Operating Conditions

Evaluate these conditions:

- Abrasive Conditions: Choose wear-resistant materials in rocky or sandy environments.

- Corrosive Conditions: Employ special coatings for water or chemical exposure.

- Space Constraints: Ensure the grapple size is suited to your working space.

Budgeting for a METDEEM Mechanical Grapple

Understand Price Ranges by Type and Size

Prices vary based on size (tonnage compatibility) and specialization (wood or rock). A basic grapple for light machines will be less expensive than upgraded ones designed for heavy-duty applications like DM08-A, which weighs more than 1000 kg.

Long-Term Value vs. Price of Original Purchase

Although upfront investment will be higher for high-end grades with hard steel alloys, they last longer—keeping the cost of ownership down in the long term.

Maintenance Cost and Requirement

Fewer moving parts in mechanical grapples than hydraulic ones translate to lesser maintenance requirements—lower downtime costs over their working life.

How METDEEM Mechanical Grapples Stand Out

METDEEM produces its attachments with the finest performance and reliability standards in mind, making them the best choice for professionals who pay high regard to quality and durability.

Higher Engineering and Quality

- Better Materials: Fabricated with superior Q355Mn steel to offer maximum durability.

- Advanced Manufacturing: Accurate fit and performance assured through precise engineering.

- Strict Testing: Each attachment is stringently tested before shipment.

Comprehensive Support and Warranty

- Reliable Warranty: Backed by 1-Year / 2,000-Hour Warranty with free replacement in the first six months.

- Expert Support: Technical advice and assistance available.

Get Your Perfect Grapple Match

Are you looking to buy the ideal mechanical grapple for your needs? METDEEM offers complete solutions for all applications and machine types. Our team can help you:

- Select the right model for your material and excavator.

- Provide technical information in detail.

- Arrange a demonstration or fitting.

- Advise on facilities for customization for special requirements.

FAQ

Q: Can I customize my grapple as per specific job requirements?

A: Yes! You can be certain that all of our products are offered in a wide range of designs. Meanwhile, we can offer a good after-sales service.

Q: Are METDEEM mechanical grapples compatible with all major excavator brands?

A: Absolutely—they’re designed with universal mounting systems cross-compatible with brands such as CAT®, Komatsu®, Volvo®, SANY®.

Q: What am I getting when I buy a grapple?

A: All accessories for installation needed, like pins & bushings, are provided with comprehensive pre-shipment inspection reports (Each attachment will be tested before despatch).