Urban Construction and Noise Challenges

Urban construction projects are subject to stricter regulations these days, particularly regarding environmental impacts, noise, and vibration. Hydraulic breakers play a key role in breaking down and digging. Yet they create a lot of noise and shaking when running. METDEEM hydraulic breakers deliver quick work, strong output, low maintenance cost and long service life. Still, as city building gets more controlled, people want tools that are smarter and less loud.

Importance of Noise and Vibration Control

Building site noise bothers nearby folks a great deal. It can break rules and slow down jobs. Smarter designs in hydraulic breakers cut down running noise. This builds better ties with neighbors. It also lets teams work longer without upsetting people or breaking local laws. Handling shaking matters just as much. Too much ground shaking harms close structures and hidden lines. That brings high repair costs and risks to safety. Plus, workers using shaky gear feel tired, lose focus, and face health problems over time. Less shaking boosts worker ease and makes machines and parts last longer.

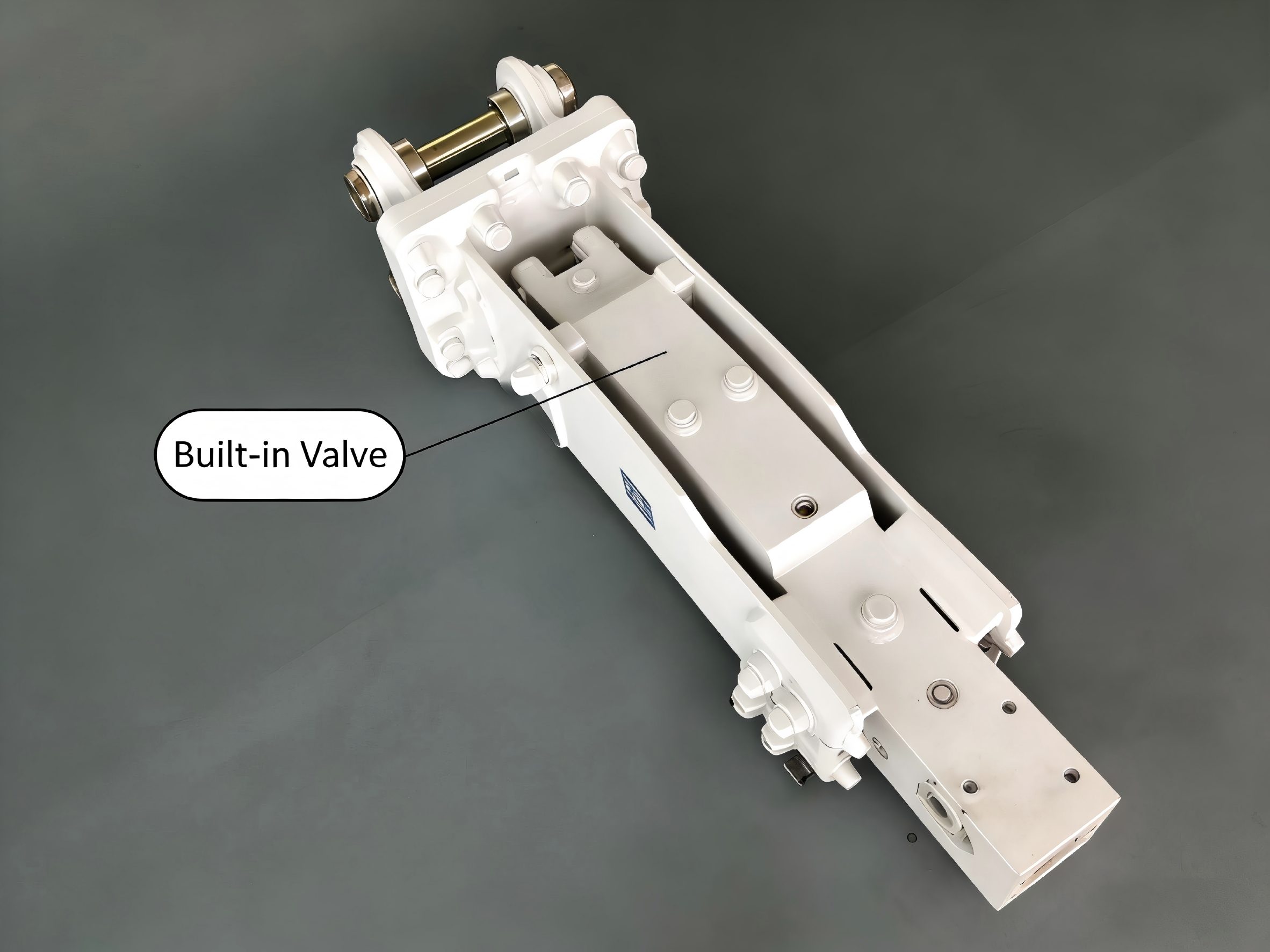

Role of Built-in Valve Technology

Divided into two categories according to flow valve classification: built-in valve (the valve is inside the middle cylinder) and external valve (the valve is outside the middle cylinder). Built-in valve tech has become a key fix in hydraulic breaker setup. Outer valve setups send power less well and make extra noise. Built-in valves handle the oil flow inside the breaker better. METDEEM’s hydraulic breakers equipped built-in valve system works quietly and steadily. It fits well in city jobs where the surroundings need care.

Noise Reduction with Built-in Valves

How Built-in Valves Reduce Noise

Built-in valve setups control oil flow inside with more care. They cut down sharp pressure jumps that lead to hydraulic shocks and loud sounds. This way of managing power inside lessens hard hits between parts like the piston and chisel. As a result, noise levels drop during jobs. The hammer’s reversing valve gets a fine grind. That leads to easier shifts and more hits per minute. Such careful work not only boosts how well it runs but also helps keep things quieter. In real use, like breaking concrete near a school, operators experience a more consistent operating sound with reduced impulse noise.

Comparison with Conventional Breakers

External valve designs generally have less integrated flow control, which can lead to higher pressure fluctuations and increased structural vibration, contributing to higher noise levels. METDEEM Box Type Hydraulic Breakers, such as DM35 Hydraulic Breaker, use a closed build. This setup blocks shaking sources and softens sounds well. Lower noise and less shaking make the hydraulic breakers easy for operators to handle. It also helps the community and the nearby areas.

Vibration Control for Sensitive Environments

Importance of Vibration Management in Urban Sites

In cities, shakes from building gear can upset key spots like hospitals. They might harm the strength of old landmarks or break fine underground networks such as waste pipes or data cables. So, keeping shakes in check goes beyond ease. It’s a main safety need. For example, near a historic church, unchecked vibes could crack walls built over a century ago.

Built-in Valve Contribution to Vibration Damping

The better oil path from built-in valves cuts back on the hammer’s pushback a lot. With more efficient internal oil flow control and reduced internal leakage, the hydraulic system operates more efficiently, which can contribute to improved fuel efficiency under the same working conditions. That saves fuel. Also, there’s less waste. This optimized impact frequency improves overall breaking efficiency, helping shorten working time compared with conventional breakers under similar conditions. Workers gain from lower shakes in their hands and arms. That improves health over the years and sharpens focus on tasks. Less wear on parts means the gear holds up better. Repairs happen less often, helping reduce component wear and maintenance frequency, which can significantly lower long-term operating costs.

Enhancing Excavator Compatibility and Versatility

Matching Hydraulic Breaker Sizes to Excavators

Right-sizing matters to pass power well from the excavator’s oil system to the breaker. Attachments that are too big or too small cause waste and quick damage. METDEEM fixes this with many breaker types made for different excavator sizes.

For example:

- DM45: Compatible with 2–5ton excavators.

- DM140: Designed for 19–24ton excavators.

- DM175: Suited for 40–49ton excavators.

METDEEM offers various hydraulic breaker sizes compatible with different excavator models.

Integration into Existing Fleets

A big plus for METDEEM’s built-in valve breakers is how simply they fit into current excavator groups. These valve systems make setup straightforward. No big changes are needed. They work with usual oil connections. This easy attach cuts wait times and skips buys of special tools.

Addressing Soil Compaction Issues Effectively

How Vibration Affects Soil Structure

Vibes without a control pack soil too tightly. This lowers how water moves through it and weakens its build. Such changes can cause base problems for new setups or mess up buried services. Soil packing hits hard near green areas or plant beds. Roots there need loose, air-filled ground. Over-packed dirt stops plant spread and water uptake. In a park-edge build, this could mean replanting costs double if vibes compact the topsoil layer.

METDEEM Solutions for Soil-Friendly Operation

Exact damping cuts extra ground hits in break work. It keeps soil building steadily while giving a strong breaking force. This fits METDEEM’s built-in valve breakers for spots that need green care, like parks, schools, or home areas. Where high shakes would not work, these tools let teams dig without long-term harm.

Environmental Benefits of Low-Noise Breakers

Supporting Sustainable Construction Practices

Box Type hydraulic breakers match today’s green building aims. They lower the site noise overall. Less noise output fits the city green rules. For a recent high-rise project in a green zone, low-noise tools helped pass inspections on the first try, speeding approvals by weeks.

Reducing Disturbance to Residents and Wildlife

Building near homes and mixed spots calls for calm machines. This cuts down on gripes from locals or upsets to animal homes. Quiet running lets shifts run longer without issues. It aids managers in holding tight timelines while keeping good neighbor bonds. In wildlife zones, like near river paths, these breakers avoid scaring birds during nesting seasons, as seen in eco-sensitive builds.

Improving Operator Comfort and Safety

Ergonomic Benefits of Low-vibration Tools

Frequent shaking can cause hand-arm vibration syndrome (HAVS) in workers. METDEEM cuts these shakes to boost safety and ease. Lower hand-arm shake cuts long-term health risks. Workers tire less on full days. That raises output without harming well-being.

Enhanced Control During Operation

Smoother tool action from built-in valve handling gives workers a better grip. This is vital in close city spots where exact moves count. Steady tool work aids handling in packed urban areas. Even feedback lowers the chances of hitting nearby setups or needing fix-ups. On a narrow alley job, precise control prevented damage to power lines just inches away, avoiding costly secondary damage.

Conclusion: Advancing Urban Construction with Smart Technology

METDEEM’s built-in valve hydraulic breakers provide a strong answer to today’s city building hurdles. They cut the noise and shaking sharply while holding the top work levels. These changes aid rule-following on tough green limits. They also lift worker ease, guard close setups, and raise site flow. With METDEEM, you will have more benefits and cost savings.

FAQ

Q: What is the main benefit of built-in valve technology in hydraulic breakers?

A: It reduces internal pressure fluctuations, allowing the main components of the cylinder to perform optimally.

Q: Are METDEEM hydraulic breakers suitable for all types of excavators?

A: Yes, METDEEM offers various hydraulic breaker sizes compatible with different excavator models.

Q: How do low-vibration breakers help prevent soil compaction issues?

A: Controlled vibration minimizes unnecessary ground impact, preserving soil structure integrity.

Q: Can these breakers be used near residential buildings?

A: Yes, their low-noise design makes them ideal for use in noise-sensitive environments like residential zones.

Q: Do built-in valves affect the power output of the breaker?

A: No, they optimize energy transfer without compromising performance, ensuring efficient breaking force with reduced disturbance.