Hydraulic breakers are a crucial piece of equipment in demolition, mining, and construction. Yet, most operators ignore the factor that truly affects performance and durability: the cylinder, or the “heart” of the breaker. How it operates, what it is made of, and how it should be maintained will enable you to achieve maximum efficiency, minimize downtime, and keep your investment safe.

Understanding the Cylinder

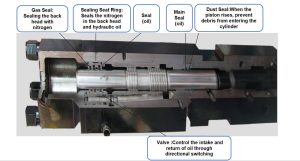

The cylinder is the core component of the breaker. It is consisted of the main body, piston, piston rings, valve, and main seals. METDEEM‘s cylinders are made of 20CrMo alloy steel, and undergo heat treatment process providing exceptional stability, wear resistance, and long-term durability.

Why It’s the Heart of the Hydraulic Breaker

A high-precision cylinder can make the breaker working more efficiently, reliably, and durable. In essence, the cylinder makes the breaker perform like a well-designed engine.

Key Functions of the Cylinder

Power output

The piston translates hydraulic pressure into kinetic energy. Smooth, precise piston motion with low friction and minimal seal wear is provided by the cylinder. METDEEM pistons are ground and polished to fine tolerances for maximum energy transfer.

Pressure Bearing and Load Distribution

Under load, the cylinder resists very large internal pressure. Forging strengthens its molecular construction, and heat treatment creates a hardened surface layer (1-1.5mm thick), which is resistant to cracking and tough. This means that the cylinder can be repeatedly struck, and the load is evenly transferred to the internal components.

Sealing and Structural Support

The cylinder provides seal integrity at high pressure and avoids hydraulic leaks that have the potential to compromise safety or performance. Its design keeps the breaker aligned and stable regardless of extreme use.

METDEEM’s Engineering Excellence

Long Lasting Materials and Precision Design

We apply only good-quality material for the production of our breaker parts in METDEEM. The hammer’s cylinder is ground internally by a CNC grinder with a single clamping operation. It provides high internal control, concentricity, and surface finish, hence every product is a standard part. We produce our cylinders of 20CrMo alloy steel and heat-treat them for full hardness and wear resistance.

Manufacturing Standards of METDEEM

METDEEM hydraulic breakers are made with high-strength alloy steel with an advanced hydraulic system design to provide robust impact force, instant penetration, and good performance. Our stringent quality control procedures, from raw material testing to finished assembly, guarantee every unit meets international standards of dependability. We also feature models such as the DM05 Hydraulic breaker, which is suitable for 0.8 ton excavators with 35 mm chisels that incorporate our highly engineered cylinders.

Longevity and Resistance in Harsh Environments

Cylinders of this material show no microscopic deforming or cracking when put under load, which improves their life span. Such characteristics qualify our breakers for harsh environments like mining and demolition applications. Our products are specifically engineered to withstand more than 1,500 hours with regular maintenance.

Importance of Cylinder Quality

Effect of Performance on Hydraulic Breakers

An optimally designed cylinder impinges directly on the hydraulic breaker’s efficiency by limiting internal movement and providing maximum energy transfer efficiency. Under the same pressure and flow rate, our cylinders work faster and produce a higher impact force. This makes them more efficient, less wear and tear, and shorter work cycle, which means less operating cost.

Common Problems due to Low-Quality Cylinders

Poor-quality cylinders will crack with pressure, misalign when badly machined, or leak when badly sealed. Cylinders from this material are not subject to microscopic deformation or cracking under stress, unlike the less expensive types that quickly wear out.

Maintenance Tips to Extend Lifespan

To get them to last:

- Seals should be checked frequently for wear.

- Hydraulic fluid must be kept clean.

- Use recommended lubricants.

- Overloading or excessive recommended levels of pressure should be avoided.

Investment in a sturdy cylinder avoids such common malfunctions and conserves time and repair money.

Choosing METDEEM for Your Equipment

Advantages of METDEEM Cylinders

When you opt for METDEEM breakers such as DM35 Hydraulic breaker or DM1550 HB30G Hydraulic breaker, you’re buying products with hardened 20CrMo cylinders for durability. Our hydraulic breakers are made from high-strength alloy steel and incorporate the latest hydraulic system design, so our equipment shows consistent power and efficiency.

Compatibility with Various Breaker Models

METDEEM’s cylinders are made into a broad array of breakers that suit worldwide brands such as Komatsu, Volvo, CAT, SANY, Doosan, and others. The product is also suitable for local and worldwide excavator brands such as CAT, Komatsu, Volvo, Sany, and XCMG, presenting ease of use to the user without issues of compatibility.

Customer Feedback and Industry Trust

The METDEEM brand Furukawa Series Hydraulic Breakers is highly recognized by overseas customers for its superb performance in safety and endurance. Mining, road construction, building, and demolition customers all experience reduced downtimes and increased productivity again and again with our durable cylinder engineering.

Conclusion

The cylinder really is the heart of a hydraulic breaker. Its material quality, precision machining, and structural configuration control performance, efficiency, and life. Selecting METDEEM cylinders guarantees efficient operation, minimizes downtime, and maximizes productivity in any application from building to demolition and mining.

FAQ

Q: Why is the cylinder so important in a hydraulic breaker?

A: The cylinder is a critical part in the control of piston motion, seal integrity, pressure distribution, and structural support—factors that influence performance.

Q: What material is ideal for METDEEM cylinders?

A: The cylinder of the hammer is made from 20CrMo alloy steel and then heat-treated to reach hardness and toughness.

Q: Are METDEEM cylinders compatible with all excavator brands?

A: Yes. The product has high compatibility with top domestic and foreign excavator brands like CAT, Komatsu, and Volvo, providing wide compatibility.

Q: How long will my METDEEM cylinder last?

A: With regular maintenance like lubrication and checks, our cylinders are easily durable for more than 1,500 hours of operating time.

Q: What METDEEM model would you need for my 2-3 ton excavator?

A: We would suggest the DM20 Hydraulic breaker, especially for 2-3 ton excavators with adjustable frequencies and spare parts.