The Role of Nitrogen Pressure in Hydraulic Breakers

In hydraulic breaker systems, the nitrogen chamber does more than simply hold gas. It acts as a key part that controls the breaker’s striking power. The pressure in this chamber plays a big role in how well hydraulic breakers work. In particular, METDEEM hydraulic breakers see wide use in mining, construction, and road demolition jobs. Keeping the right nitrogen pressure helps deliver steady hitting power. It also cuts down on wear inside the machine and boosts how efficiently it runs. When you get the pressure just right, the breaking force gets stronger, and the work goes more smoothly. This makes it an essential part of everyday equipment care. This article looks at how nitrogen pressure shapes the work of METDEEM hydraulic breakers in different tasks.

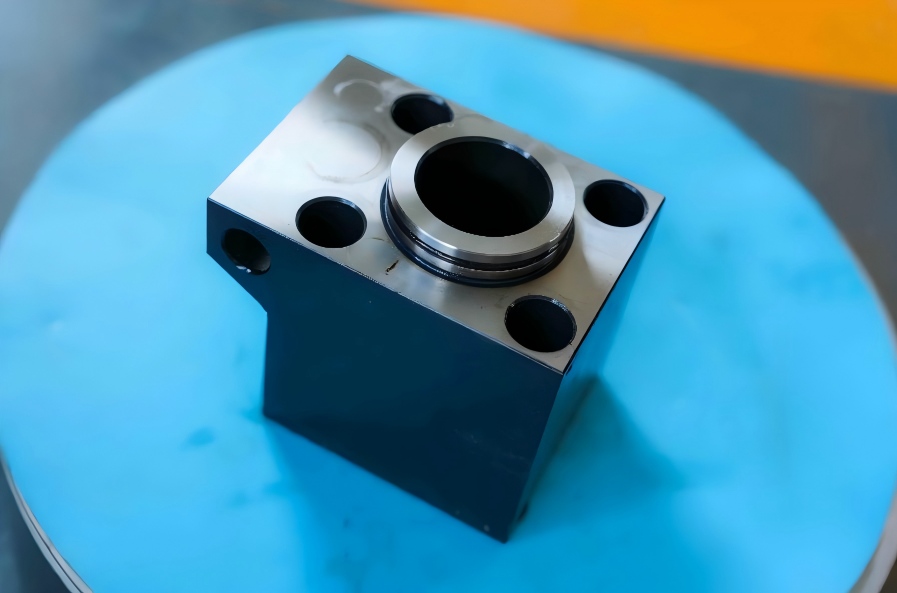

Understanding Hydraulic Breaker Mechanics

The Function of the Nitrogen Chamber

The nitrogen chamber functions as an energy storage and recoil damping system, assisting piston return and stabilizing impact energy throughout each operating cycle.

The nitrogen chamber has two main jobs. First, it holds nitrogen gas under pressure. Second, it works as a buffer against recoil. It keeps compressed nitrogen to soak up the kickback and help the piston move back. In every strike, the gas squeezes and stretches to handle backpressure. This setup lets the piston get ready quickly for the next hit. By managing backpressure, it controls the energy in each impact. As a result, it directly helps the breaker run at its best.

Nitrogen Pressure and Breaking Force Relationship

How Pressure Affects Impact Energy

The nitrogen pressure in the chamber sets how hard the piston snaps back after a stroke. Higher nitrogen pressure improves piston rebound efficiency, which can indirectly stabilize impact energy and support consistent blow frequency when matched with proper oil flow and valve timing, which work great for tough stuff like granite or concrete with rebar. But pushing the pressure too high brings risks. It can make the impacts too rough or cause piston instability or lateral misalignment, leading to uneven impact energy distribution and accelerated component wear, which causes uneven running and possible harm to parts inside.

Effects of Underpressure on Performance

At the same time, too little nitrogen can hold back the breaker’s output. When levels drop low, the striking power weakens, and the hits come less often. The piston might drag on its way back, making each strike softer and stretching out the time between them. In the end, this slows down how well it breaks through rock and speeds up damage to the seals inside and the chisel.

Common Pressure Imbalance Issues

Consequences of Excessive Pressure

If nitrogen levels go beyond what the specs call for, the uncontrolled piston rebound and excessive rebound velocity, accelerating internal component fatigue. It wears out components faster and cuts down on how precise the strikes land. That matters a lot in jobs like careful demolition or digging trenches.

Consequences of Insufficient Pressure

When pressure falls too low, the breaker loses its quick response. The piston returns slowly, and the hits lack strength. Workers spot longer cycles, more fuel use, and less overall output. This hits hard in tough spots like mining sites or big construction projects.

Pressure Optimization for Different Applications

Various job sites call for specific nitrogen pressure levels. For hard rocks, you need a higher starting pressure to break through effectively. Softer ground, however, calls for a lighter touch to spare extra strain on the parts. By matching the pressure this way, you extend the machine’s life and get the best results.

Application-Based Adjustment Guidelines

For Mining Breakers (Hard Rock)

In mining areas with dense rock, hydraulic breakers perform well at the upper pressure range of 28–32KG/cm³(approximately 2.8–3.2 MPa), following METDEEM guidelines. These models use tough forged 20CrMo cylinders and treated 42Cr chisels. Such parts stand up to the strong forces inside during heavy use. For instance, on a quarry site breaking basalt, operators often set pressures near 30KG/cm³(approximately 3 MPa) to maintain steady progress without overheating the system.

For Construction Demolition (Medium Rock)

Units such as DM35 Hydraulic Breaker Side Type, popular for building tear-downs, run smoothly at middle pressures of 16–18KG/cm³(approximately 1.6–1.8 MPa). This balance keeps the strikes even and avoids overloading the piston or valves. In a typical urban demo job on old concrete slabs, this setting helps crews finish sections faster while keeping the excavator stable.

For Trenching or Asphalt (Soft Rock)

For tasks like digging trenches or fixing roads, where the material gives way more easily, models like DM35 operate efficiently at lower nitrogen pressure ranges around 12KG/cm³(approximately 1.2MPa). This approach keeps the chisel sharp longer and lessens the jolt to the excavator’s arm.

Engineering Best Practices for Charging Nitrogen

Precision Charging Techniques for METDEEM Breakers

To keep all METDEEM models working at peak, the company suggests special charging kits made for their gear. Always check the surrounding temperature before finishing the charge. Heat can change how the gas expands, so it affects the pressure you read. In field tests, technicians note that a 10°C rise might bump readings by 1-2KG/cm³(approximately 1–2 MPa), so adjustments prevent over- or under-charging.

Maintenance Routines to Sustain Optimal Pressure

Regular checks form the backbone of good care. Look closely at the seals in the nitrogen chamber for any drips or signs of wear, particularly after long runs or weather shifts. METDEEM advises recharging every 100–150 hours. Do it also before tackling a new type of material, based on how hard you push the machine.

Integration with Other Performance Parameters

Synchronization with Oil Flow and Piston Timing

The right nitrogen pressure needs to match the flow of hydraulic oil and the valve’s timing. When everything lines up, oil moves smoothly with the piston, passing energy without bubbles or delays.

Impact on Cylinder Breaker Longevity

Steady nitrogen levels keep sudden stresses away from the cylinder setup. With even pressure, parts inside face less strain, which stretches out how long they last. This cuts time lost to repairs and lowers costs for new parts. For big projects or rental outfits, it means fewer stops and steadier work.

Conclusion: The Central Role of Nitrogen Optimization in Performance

Keeping the nitrogen chamber pressure spot on goes beyond basic upkeep. It stands as a key way to tune the machine for top results. The right pressure in the nitrogen chamber forms the base for strong breaking in METDEEM hydraulic breakerrs. From handy sizes like DM35 to heavy mining ones like DM230 Hydraulic Breaker Top Type, setting levels to fit the job brings better output, less strain on the mechanics, and smaller running expenses. METDEEM builds each part—from precisely ground cylinders to treated pistons—to shine under these tuned setups. With strong design skills and quality checks at every step, METDEEM keeps meeting and beating what customers need.

FAQ

Q: How often should I check the nitrogen pressure in my METDEEM hydraulic breaker?

A: It’s recommended to check every 100–150 hours of operation or before starting work on a new material type.

Q: What happens if I use too high nitrogen pressure?

A: Excessive pressure can cause harsh impacts, reduce control accuracy, and damage internal components like the piston or seals.

Q: Can I use the same nitrogen setting for all rock types?

A: No, different materials require different pressures—adjust according to rock hardness for optimal performance.

Q: Is it safe to recharge the nitrogen chamber myself?

A: Yes, if you use a calibrated charging kit compatible with METDEEM breakers and follow safety protocols precisely.

Q: Does temperature affect nitrogen chamber performance?

A: Yes, temperature changes can alter gas volume; always adjust charge levels based on ambient conditions during setup.