Experts recommend:

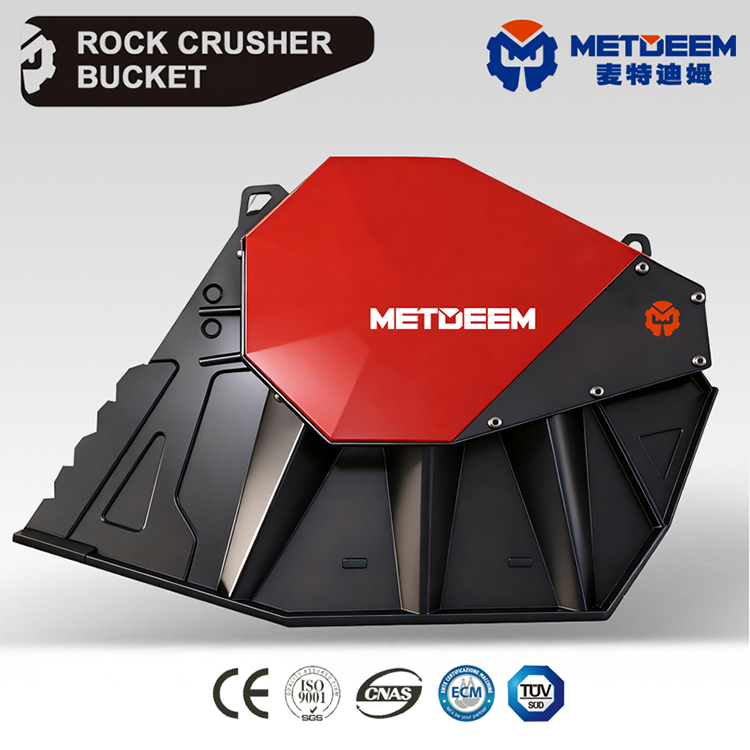

Main features of Metdeem Rock Crusher Bucket

1.METDEEM crushing bucket integrates the functions of crushing and screening. After installation, it can directly crush construction waste, ores, etc. on site without the need for additional transportation to a fixed crushing station. This greatly reduces material handling and intermediate processing steps, significantly improving operational efficiency.

2. METDEEM, through its adjustable discharge port, can precisely control the output particles ranging from 30 to 150mm, meeting the requirements of different working conditions and adapting to diverse recycling and reuse needs.

3. METDEEM Crushing Bucket: The main body of the bucket is made of high-quality manganese steel plate. While ensuring the overall structure of the bucket is lightweight, easy to install and operate, it also has super wear resistance and impact resistance, ensuring that it can be durable and long-lasting when crushing hard materials such as concrete and rocks, and extending its service life.

4. The unique low center of gravity body design of the METDEEM crushing bucket effectively suppresses the vibration generated during operation, making the entire machine operation more stable and precise. On-site crushing reduces the pollution of dust and noise to the surrounding environment and is an efficient and environmentally friendly solution.

Metdeem Rock Crusher Bucket

1. Tonnage matching

When choosing the METDEEM crushing bucket, excavators of different tonnages need to be matched

The hydraulic flow rates of different types of buckets must meet the equipment parameter requirements

For large-sized buckets, it is necessary to ensure that the excavator has sufficient counterweight to guarantee operational stability

2. Adapt to working conditions

The METDEEM crushing bucket is suitable for various projects such as construction waste crushing, limestone and sandstone crushing, granite and basalt crushing, and concrete recycling.

3. Efficiency optimization

When the rated power of the equipment reaches 70-85%, the METDEEM crushing bucket achieves the best crushing efficiency.

The wear of the jaw plate should be checked every 200 hours of operation.

When in operation, it is necessary to regularly clean the discharge port, which can increase efficiency by 15-20%.

| ltem/Model | Unit | DM-06 | DM-06 | DM-08 | DM-10 |

| Capacity | m³ | 0.4 | 0.67 | 0.8 | 1.2 |

| In Size | mm | 785*480 | 960*500 | 1010*500 | 1100*500 |

| Weight | kg | 1400 | 3000 | 4100 | 6000 |

| Out Size | mm | 13-80 | 13-80 | 13-80 | 13-80 |

| Working Pressure | bar | 250-270 | 250-300 | 250-300 | 250-300 |

| Working Flow | lpm | 90-100 | 120-150 | 200-230 | 230-260 |

| Excavator | ton | 15-18 | 15-18 | 25-30 | 30-40 |

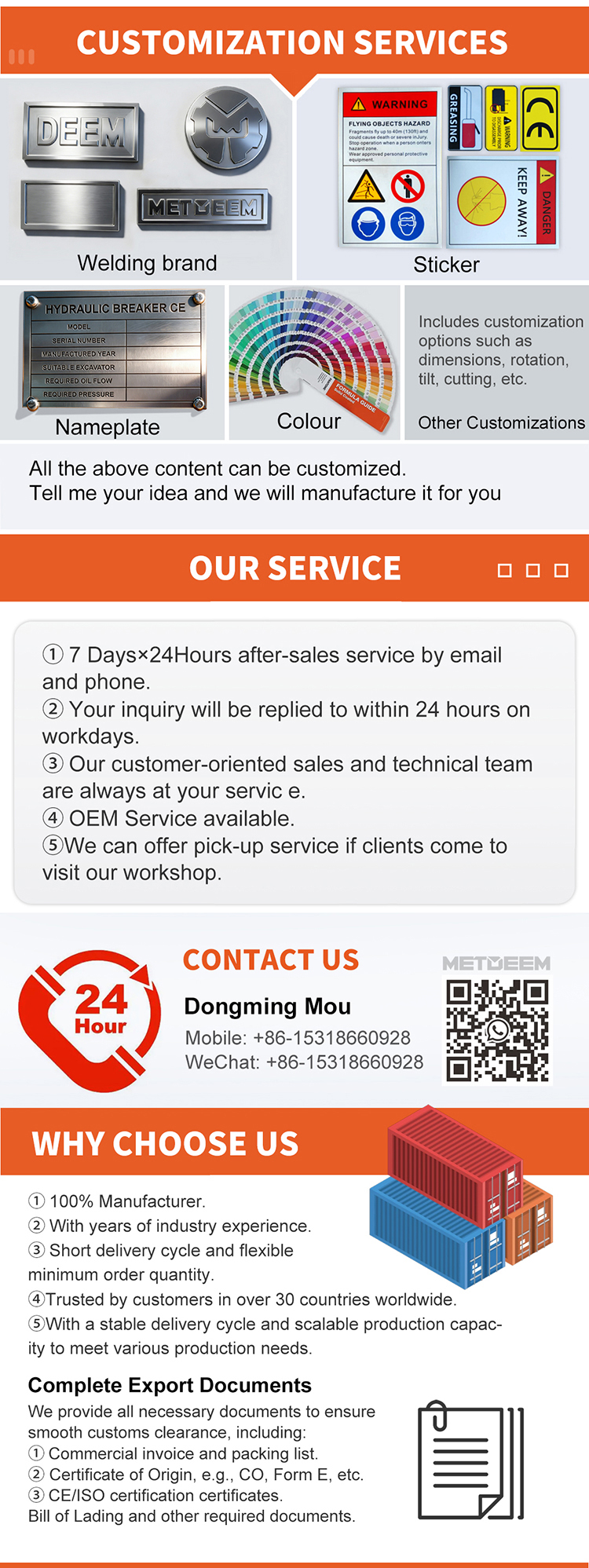

Our Services–METDEEM Manufacturer Service

Warranty–METDEEM After-sales guarantee

Yantai Hansheng Heavy Industry Co., Ltd.

Technical support: Beijing Xinhulian Technology Co., Ltd