Hydraulic breakers in mining and demolition deal with tough conditions in the construction field. These environments are typically filled with abrasive dust, fragmented rock particles, and construction debris. Such materials can slip into key parts of the machine. The cylinder assemblies of hydraulic breakers suffer the most from this dirt. Dust grains sneak past the sealing setup. They cause small scratches that wear down surfaces and cut down on how well the tool works.

Importance of Dust Seals in Hydraulic Breakers

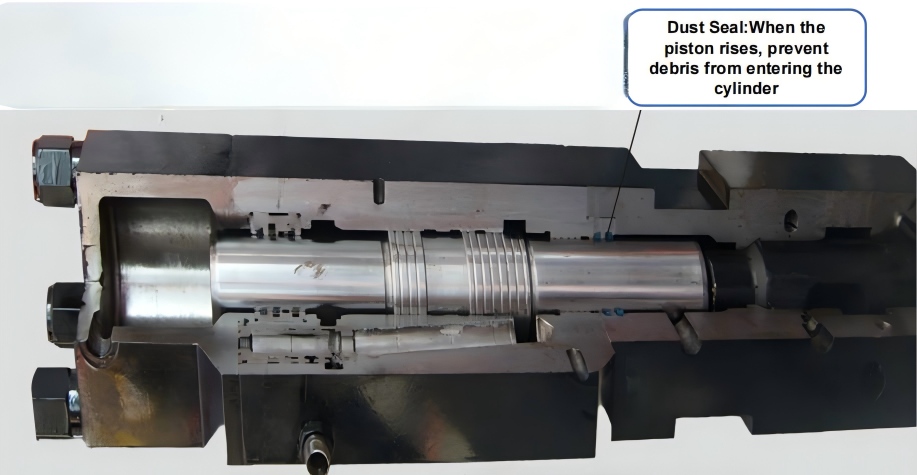

Dust seals stand as the main shield against outside dirt. Without good dust sealing, even the strongest hydraulic breaker risks early breakdown. These seals block dust and junk from getting into the cylinder body. There, they might harm the inside surfaces and the quality of the hydraulic oil. METDEEM’s top dust seals fit these rough spots. They help keep the life and work of our hydraulic breaker cylinders strong.

Understanding Cylinder Wear Mechanisms

Abrasive Wear in Hydraulic Cylinders

Hydraulic cylinders are made with exact cuts. They need close fits between pistons and cylinder sides. In rough settings, dust grains can slide in through weak seal spots. These grains make tiny cuts and wash away the inner layer of the cylinder. Over time, this harms sealing areas and leads to seal breakdowns. As internal wear progresses, internal leakage increases, leading to reduced operating efficiency, slower response times, higher oil temperatures, and increased fuel consumption. Plus, there is less oil waste. But if wear builds up, hydraulic work falls off a lot. This cut hits the power and adds stress to the parts.

Internal Contamination and Its Consequences

Contaminants that bypass the dust seal affect not only metal components but also the hydraulic fluid and sealing system as a whole. It also dirties the hydraulic oil. Dirty oil raises friction between moving pieces. It boosts heat during runs and speeds up part damage. This bad loop often means more fixes and surprise stops for vital tools like mining breakers or hydraulic pulverizers. Weak seals let dirt in. That harms the main parts fast and raises the call for frequent repairs or new pieces.

The Role of High-Performance Dust Seals

How Dust Seals Protect Cylinders

METDEEM’s dust seals aim to stop small dirt bits from reaching key spots in the hydraulic breaker. They form a continuous protective barrier at dynamic sealing interfaces, such as where the piston goes in. This shields the main seals from quick damage. So, the main seals and inside surfaces stay whole. As a result, the hydraulic oil stays clean. Key parts like pistons and valves keep working well for longer runs.

Key Features of METDEEM Dust Seals

What makes METDEEM’s dust seals special is our work on materials and shapes. We use tough materials that last against wear. Our dust seals keep their bend over wide heat ranges. They also fight off harm from oils or outside factors. Their custom shapes give a firm seal during movement. They adjust for rod bends or pressure changes. This suits them well for the DM53 Hydraulic Breaker Top Type. It has a 53mm chisel and fits 2.5-4.5 ton excavators.

Benefits for Equipment Longevity and Cost Reduction

Extended Cylinder Life with Proper Sealing

Adding strong dust seals cuts down on rough rubs between dirt and cylinder insides. Less rough contact slows damage to cylinder walls. This holds off scratches and holes—usual signs of part failure. It stretches the work life of the factory or replacement cylinders. Our exact CNC-ground cylinders in DM75 Hydraulic Breakers Side Type gain from this guard. They keep their round shape and tight fit for many hours.

Impact on Maintenance Frequency and Costs

Less dirt getting in means fewer part breaks and less need for fixes on hydraulic pulverizers or seal swaps. Breakdowns drop, so stops on mining breakers or hydraulic breakers cut back. In the long run, this saves big on parts, worker time, and machine idle periods.

Application in Harsh Environments

Performance in Mining and Demolition Sites

Our dust seals face strict tests in heavy dust setups. This checks their strength in the hardest spots. Whether cracking tough rock or thick concrete in mine holes or city tear-downs, METDEEM seals keep their build over long shifts.

Compatibility with Various Hydraulic Breaker Models

METDEEM’s dust seals fit right into our whole line of hydraulic breaker systems. Our hydraulic breakers get easy updates or fixes with swap seals that match factory rules. These seals work for both new installs and later services. They offer choices for users in different jobs.

Design Considerations for Optimal Seal Performance

Material Selection for Harsh Conditions

Picking the right seal material matters a lot for lasting strength. METDEEM picks flexible polymers that stand up to scrapes, heat shifts, and chemical hits seen in heavy work. High-resilience polymers resist abrasion, heat, and chemical exposure. This keeps our dust seals soft and useful even after thousands of work hours.

Seal Geometry and Installation Precision

Our dust seals have exact-fit shapes made to cut out any space where dirt might slip in. Plus, the right setup is key to holding steady seal work under changing pressures. Precision-fit designs minimize gaps that allow particle ingress. This matches our main build way: each cylinder body gets cut on a CNC grinding machine and done in one hold.

Conclusion

METDEEM high-performance dust seals play a vital part in guarding hydraulic breaker cylinders from rough harm in dusty spots like mining or demolition work. By making a solid wall against dirt, these seals help save inside parts, cut fix times, drop full ownership costs, and extend the work life of the gear a great deal. Overall, they boost reliability in daily operations, helping crews meet deadlines without constant worries over breakdowns.

FAQ

Q: What causes hydraulic breaker cylinders to wear out quickly?

A: In abrasive environments like mining or demolition, dust and debris can enter the cylinder assembly, causing accelerated abrasive wear and contamination-induced seal failure that leads to rapid wear.

Q: How do METDEEM dust seals differ from standard seals?

A: METDEEM dust seals are designed with advanced materials and geometries that provide superior resistance to particle ingress under extreme conditions.

Q: Can upgrading to high-performance dust seals reduce maintenance costs?

A: Yes, by preventing internal contamination, these seals help reduce breakdowns and extend service intervals, lowering overall maintenance expenses.

Q: Are METDEEM dust seals compatible with all breaker types?

A: They are specifically engineered for compatibility with METDEEM hydraulic breakers but can also be adapted for use in other compatible systems.

Q: What is the impact of poor sealing on hydraulic pulverizer repair frequency?

A: Poor sealing allows contaminants into the system, accelerating wear on key components and increasing the need for frequent repairs or part replacements.