When you start a demolition or trenching job, picking the correct tools decides whether you finish on time and within budget. A good excavator ripper helps you work faster, keeps your machine from wearing out too soon, and stops small problems from turning into big delays. Choosing the wrong excavator ripper can lead to slower project progress, increased wear and tear on machinery, and higher maintenance costs.

At METDEEM, we know every construction site is different. Some days you fight frozen dirt, other days you hit solid rock. That’s why we build a full line of strong rippers that can handle almost anything you throw at them.

Understanding Excavator Rippers

What Is an Excavator Ripper

An excavator ripper is a tough attachment that breaks hard ground before the bucket even touches it. An excavator ripper functions as the primary tool for breaking the surface, enabling the rest of the excavation process to proceed efficiently. It works great in compacted clay, cracked bedrock, or ground that’s frozen solid for months. METDEEM brand excavator rippers are made exactly for opening up hard-packed, rocky, or icy soil. Crews use them every day in demolition work, pipeline trenching, mining sites, and land clearing.

How Rippers Work in Projects

The ripper puts all the excavator’s power into one sharp point. That single point splits rock and frozen layers instead of pushing against a wide bucket face. This leads to enhanced bucket penetration, reduced fuel consumption, and prolonged wear life of the bucket teeth, providing long-term operational efficiency.

Matching Ripper to Project Type

For Rock Excavation Projects

Rock jobs need raw strength. METDEEM Excavator Ripper handles weathered rock and hard soil without trouble. Contractors in quarries and road cuts use them daily. We build the main body from thick Q355 manganese plate steel and the pin shaft from 42CRMO alloy steel. These materials stand up to constant hammering. The DM06 Excavator Ripper has a sharp tooth angle that bites deep even into basalt and granite layers.

For Frozen Ground or Permafrost

Ice turns dirt into concrete. A regular bucket just skates across the top. METDEEM rippers are built for exactly these cold, hard condition. The single-shank design is narrow, so all the breakout force goes straight down into the frost. Heat-treated carbide-tipped teeth are designed to retain sharpness even in temperatures as low as –40 °C, ensuring optimal performance in extreme cold conditions.

For Secondary Demolition Tasks

After the building comes down, you still have concrete slabs and old foundations in the way. Here, you need control, not just power. METDEEM rippers let the operator pick apart rebar-filled concrete without scattering debris everywhere. Single-shank or double-shank choices give you the right tool for the moment. Many customers switch between the two on the same job—one for cracking big slabs, the other for cleaning between rebar.

Key Selection Factors

Excavator Weight Compatibility

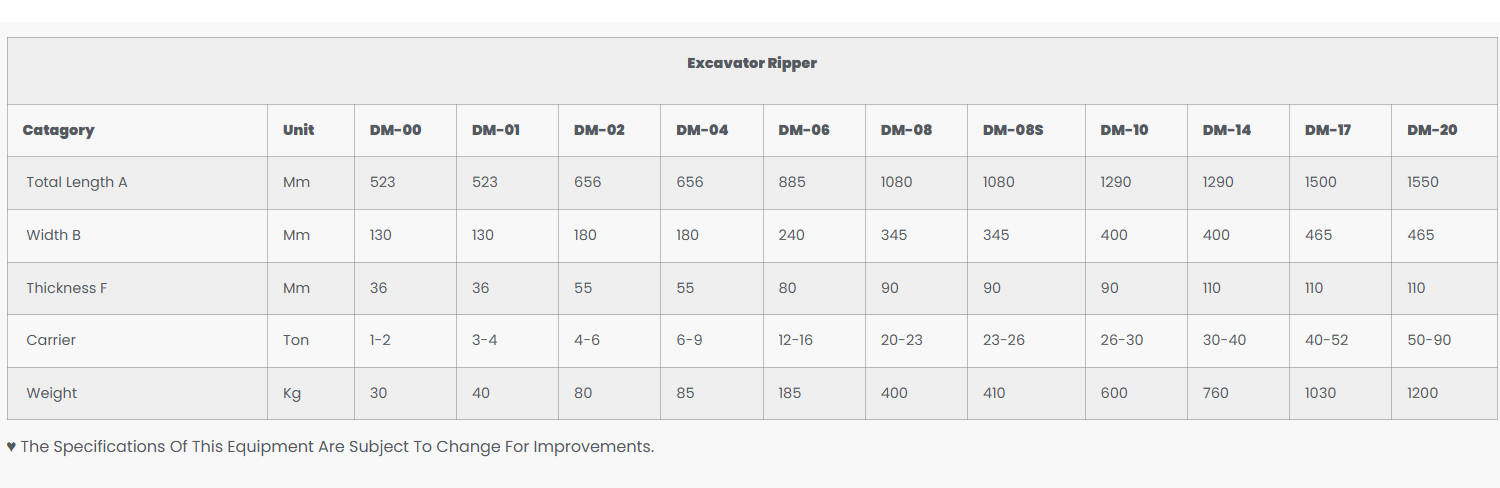

Never guess the size. The ripper has to match your machine’s weight class perfectly. METDEEM covers everything from small machines to giants:

- DM-00 for 1-2 ton mini excavators.

- DM-02 for 4-6 ton machines.

- DM-08for 20-23 ton class.

- DM-20 for 50-90ton heavy excavators.

Get the match right, and the ripper feels like it was born on your arm.

Material Strength and Build Quality

Cheap steel bends the first time you hit rock. We use Q355 manganese plate for the body because it flexes just enough without cracking. The 42CRMO alloy steel pin shaft laughs at side loads. After thousands of hours in quarries, these parts still measure within factory tolerances.

Tooth Design and Tip Geometry

- Single-Shank vs Multi-Shank Options: Single-shank rips the toughest stuff—solid limestone, permafrost, heavy clay. All the force hits one point, so it punches through. Multi-shank covers more ground in softer dirt or when you just need to scarify the surface before grading.

- Replaceable vs Fixed Tips: Tips wear out—that’s normal. Replaceable tips let you change the worn part in the field with a hammer and punch. Five minutes later, you’re back ripping. Fixed tips cost less up front but need welding when they’re gone.

Mounting and Installation

- Fitment Compatibility with Quick Couplers or Pins: METDEEM rippers fit KOMATSU®, HITACHI®, CAT®, DOOSAN®, VOLVO®, and most other major brands. You can order pin-on style or quick-coupler ready.

- Ease of Installation and Removal: Installation efficiency is critical, which is why METDEEM’s ripper design ensures easy attachment changes with minimal downtime. Our design uses only four main pins on larger models. Grease fittings are easy to reach. Swap from bucket to ripper in under fifteen minutes once you’ve done it a couple of times.

Why Choose METDEEM Rippers

Engineering Excellence and Customization Options

Each job presents unique challenges. For deeper frost penetration, METDEEM offers customized ripper shanks tailored to specific job requirements. Want extra side wear plates for abrasive sandstone? Tell us what you face, and we build it. From special tooth shapes to custom paint colors, we’ve done it all.

Proven Durability in Harsh Conditions

We test every new design in real quarries and frozen pits, not just on paper. Every METDEEM Excavator Ripper comes with a straightforward warranty: one full year or 2,000 hours against defects in material or workmanship. If it breaks because we built it wrong, we fix it—no questions.

Full Support from Selection to After-Sales Service

Send us a message, and you’ll hear back within 12 hours, usually much faster. We ask about your machine model, the material you fight every day, and how deep you need to go. Then we recommend the exact model that makes your crew smile at the end of the shift.

Conclusion

Picking the correct excavator ripper is one of the easiest ways to save time and money on tough demolition and trenching jobs. Think about your ground conditions, match the ripper size to your excavator, and choose strong materials that last. METDEEM gives you proven tools, a real-world warranty, and people who actually understand job sites. When the ground fights back, make sure you have the right ripper on the arm.

FAQ

Q: What size ripper do I need for my excavator?

A: Match the ripper to your excavator tonnage. METDEEM has models from 1-ton minis all the way to 50-ton machines.

Q: Can I use one ripper type for all soil conditions?

A: Different ground needs different tools. Hard rock and deep frost love single-shank rippers. Softer or mixed soil often works faster with multi-shank designs.

Q: How often should I replace the ripper tip?

A: Depends on how hard you work it. In heavy rock, check every 200–300 hours. Replaceable tips make the job quick and cheap.

Q: What makes METDEEM rippers more durable than others?

A: We start with a thicker Q355 manganese plate and 42CRMO alloy steel, then heat-treat everything the right way. Real quarry and permafrost testing proves they last longer.